| Date: 07-30-2019 | |

| Number of Hours: 34 | |

| Manual Reference: no ref |

I’ve been about a week on this part of the pant refit. While I was also working on the canopy fit this was the main task every day.

The back half of the pants being only two ply weigh very little. They also tend to oil can and will not be strong enough. I decided to use the technique from the Chapter 3 Education section of the plans. This has a bit of foam glassed in place that becomes amazingly strong.

I started just making up a foam wedge as you see above, They are so light a breeze will blow them away. I did one side, let it cure and then turned them over and did the second ‘strips’.

After microing these in place and after that cure I covered them with two plies of BID. I probably could have just used one ply in retrospect. Wow suddenly I have very strong rear wheel pants.

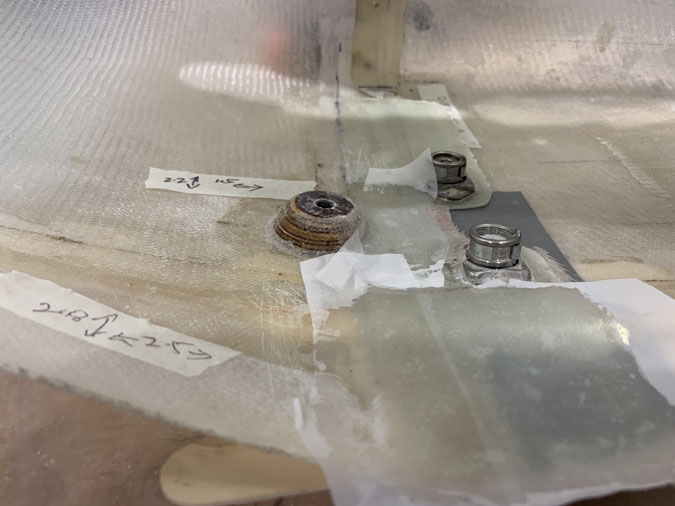

The next issue I knew was coming. As I am insisting on the rear pant section being the ones that come off and on with camlocs. Guess what? I just miss out on easy access to the tire valve by about half an inch. I could get a filler head in there but it is tough. I made a cutout for access. Easy, except I now have a hole in my pants. Yuk yuk… not all that funny.

Here’s the problem better illustrated. Of course this is all part of the plan.

Meanwhile I had to fix another problem. Where I had added glass for the camloc lip right at the bottom it had set about .25″ inboard. This is exactly where the pant and tire are close, I lopped off the offending glass and added more plies sitting correctly to both pants. At the same time I added glass on the inside of that cutout to make a lip.

This might be easier to see, extra new glass on the bottom of the pant and a whole lot of lip glass in the middle. That lip is needed for the next outside ‘tab’ layup.

Here’s the outside tab that will sit in the lip.

Yes its a mess. I also added to the ‘tab’ outside with some extra flox so I could get the shape more exact. That initial tab layup was three plies underneath and one on top to make a sandwich.

Clear as mud? Well here’s the lip around the tire stem cutout after some cleaning up.

Here’s the tab after a bit of a clean up as well. It will be ‘pretty’ very soon, I promise.

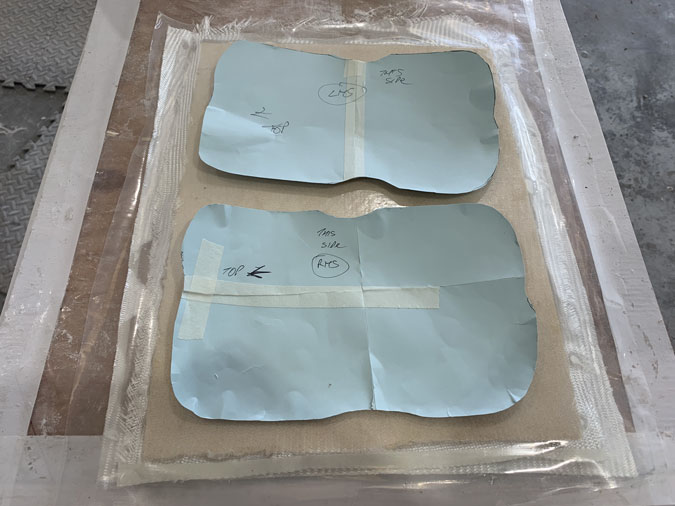

Meanwhile back in the rear of the pants, more was needed. I made up a slab of foam with just one ply a side and that has had a few days to cure. The concept here is that I need to close off the rear pant about 2.5″ back from the lip cutout. This is so that it doesn’t fill with mud and FOD or even snow from less that ideal runways.

Above is the slab of glassed foam and paper cutouts I made of the pant openings a couple of inches in.

After a bit of trimming you can see I’m on the way to a good fit.

After more trimming I microed the baffles in place. After that cured I added one ply 1″ tapes to finish off. Wow those back halves are rock solid and still not too heavy.

Lots more to do yet on these wheel pants. I spent a couple of hours fitting them and opening up the tire area. Now I’m not happy with what I just had to cut away to get the necessary clearances. Of course I have a plan to correct this.