| Date: 07-14-2019 | |

| Number of Hours: 20 | |

| Manual Reference: no ref |

This refit continues, bit by bit.

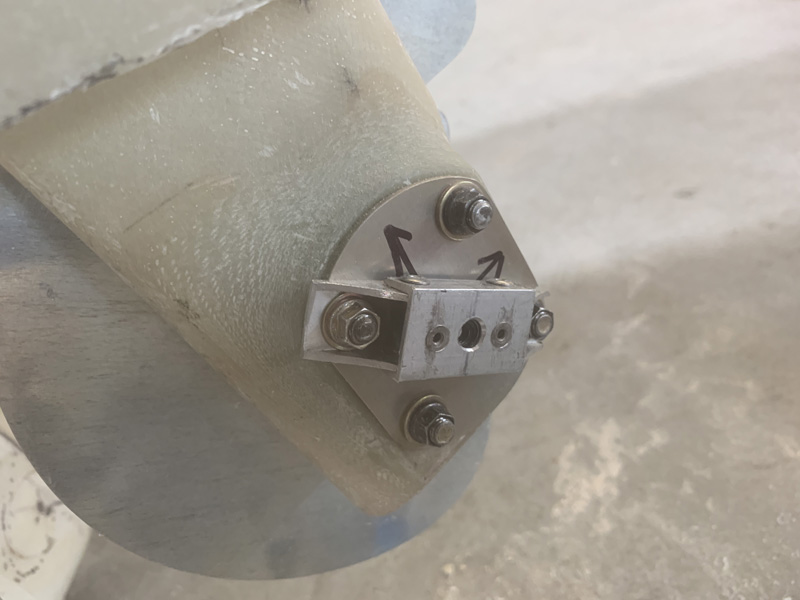

Remember this new nutplate fitting? I then tried to fit a nutplate inside and it was about 1mm too narrow. Yes I checked before I made it but I was still wrong. Yes I only had to make it in two parts because I couldn’t get a piece of box aluminium the correct height as I did for the other gear leg.

This is the remake of that which works out and gobbles up another hour or so. Maybe I could have made a hat section out of steel and careful bending? Well maybe next plane (HA!) or if I get some sheet metal skills. For now cut and shut with existing pieces is more in my wheel house. Probably weighs less in ally and doesn’t need a prime and paint either.

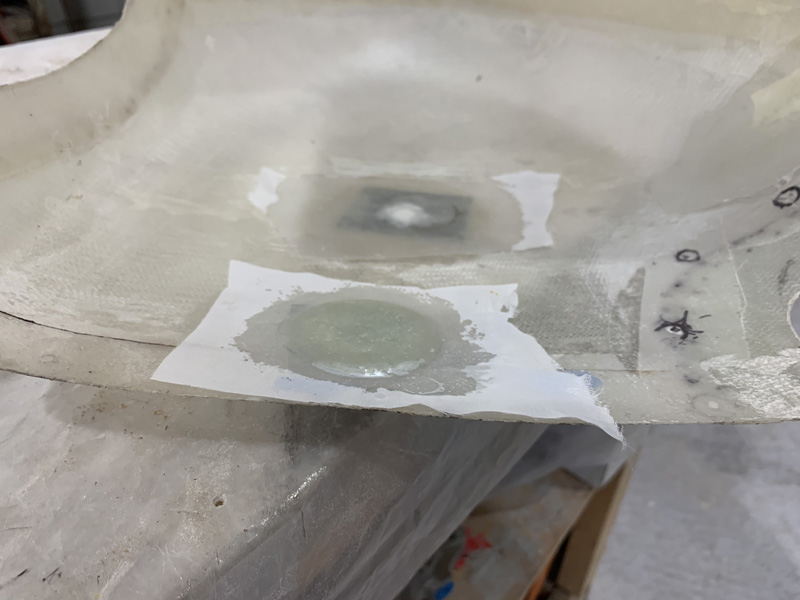

The next little issue is that I need to have the pant thick enough to do a counter sunk hole on the outside so that I have minimum drag here. Why have a screw in the breeze if its not necessary? I also need slight padding to manage the gap between the fitting on the strut and the inside of the pant as you see above. This way I can exactly control how the pant sits on the side.

I went for a 12 ply layup as thick enough. I tried doing it in one go and threw that mess away. Making 12 separate one ply circular layups on plastic and foil and then stacking them one by one works for a really tidy result.

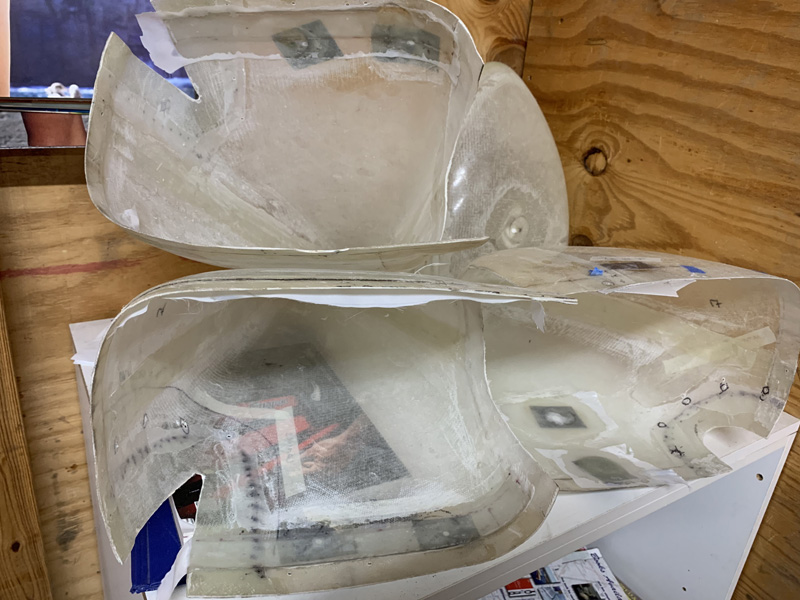

Here’s another issue after cutting away the old hard points that were not needed. The sides of the pant are was not thick enough to support the coming hardware fittings so I’m adding a three ply BID strip to the front halves in four places.

I’ll have to add to the top section later as well depending on how other things work out.

I also has to do a couple of 1 ply patches over some old hardpoint holes. They got some micro in the holes as well. This seemed enough for this cycle and the whole mess got to sit around for the epoxy to cure.

Next up I refitted the pants and added a few more clicos. At this point I’m satisfied that the pants attachments work with the new small gear leg brackets. They are rock solid and all lined up OK.

Now it would have been great to do the next part on the gear leg but there is no access. I pulled the pants off and reassembled them with clicos, hot glue and sticks.

Here we are on the inside. See that long flange on the right side. I really wish that was on the left side.

This pic shows one of my 12 ply hardpoint layup spacers too. Anyway, with the pant assembled from the outside I am able to remove the flange. Yes it was a little tricky and I had four of them that had to go… but not at the top. I’m hoping my idea works out for that area.

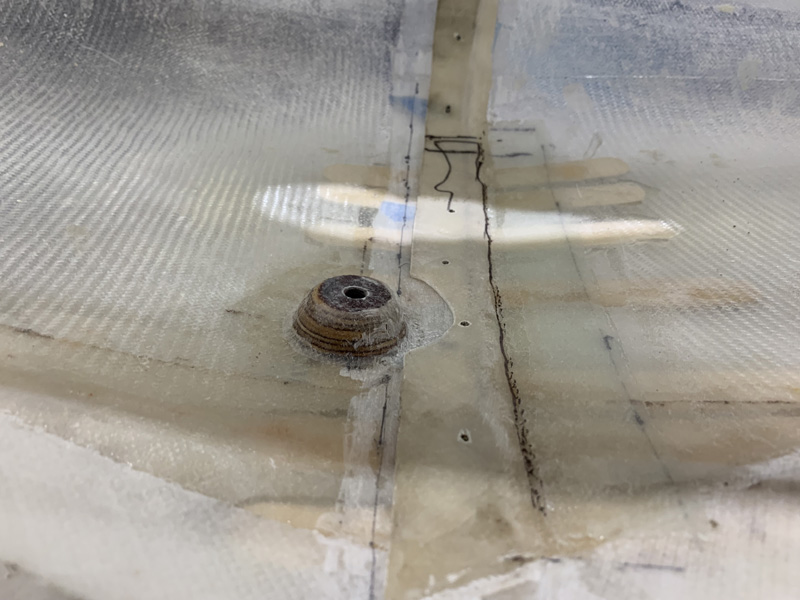

I’ve gone for a six ply flange. Here it is above just before I cut it into four pieces. I still really like the layup on plastic and foil method.

Here you see one of the four new flanges installed.

I’ll give it at least two days before trying to get the halves apart and find out if I’m on the right track with this new attachment plan.