| Date: 08-01-2020 | |

| Number of Hours: 32 | |

| Manual Reference: 10_1 Roncz Plans |

The 737-800 has three Vortilons per wing, so why wouldn’t my Long-EZ?

When the original GU canard was updated with the ‘Roncz’, this new canard created more lift. My understanding is that this narrowed the gap between when the main wing stalled after the canard stall. To increase this gap and retain a very safe flying quality of the aircraft, the main wing efficiency was improved with these little ‘fences’.

I am making them now so that they can be painted separately and then installed after the main wings are painted. This way if they ever need to be removed, say if one was damaged, its not a repaint of the wing.

You can always tell a Long-EZ owner at the beach, that will be the person with the deep scars in their back from bumping into these things while working on the plane. This is a vortilon on my flying Long-EZ. I’m sure DNA testing on the very worn tips would detail the previous three owners …and myself.

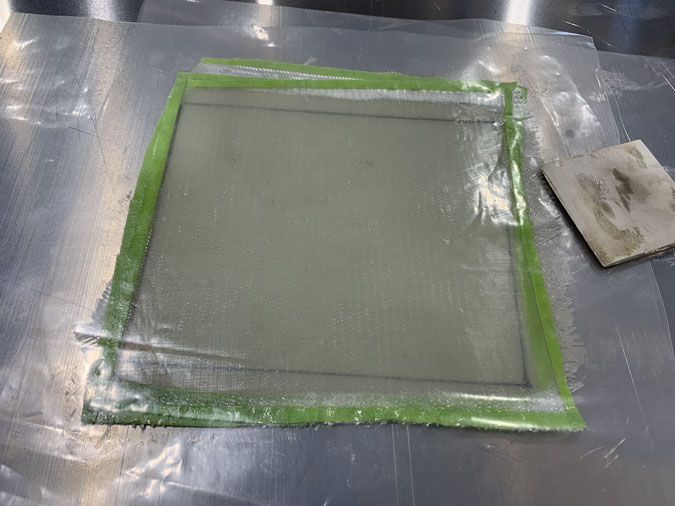

We start with 4 plies of BID at the usual 45 degree bias.

Fortunately my flying plane came with the Roncz canard plans in full size. On that plane it originally had a GU canard and the builder made another one as the upgrade came sometime after 1980. He had #74 plans so it was pretty early on.

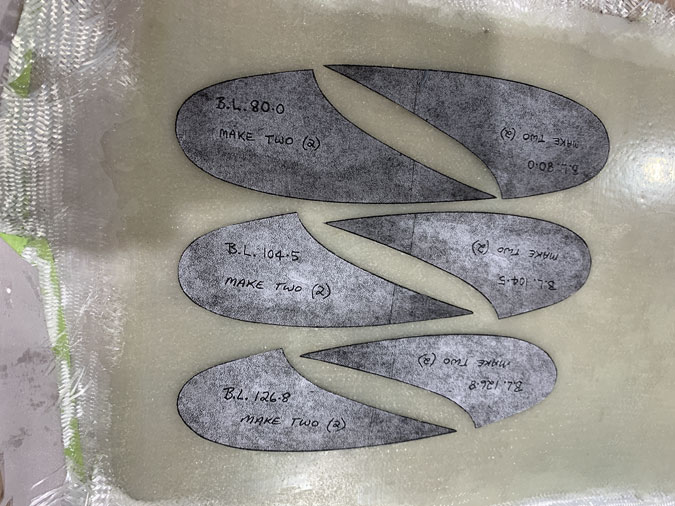

I just did a copy on my printer, cut them out and glued them onto the cured glass ready to cut out. Easy.

Here we are cut out. I was a bit disappointed that the center line was not drawn in on the plans. I had a go on my own. This is meant to line up with the longerons. The metal piece is a template that gets you the correct angle for installation. I used some scrape aluminium.

Their position on the wing is fortunately given as a measurement along the leading edge and very easy to set up per plans.

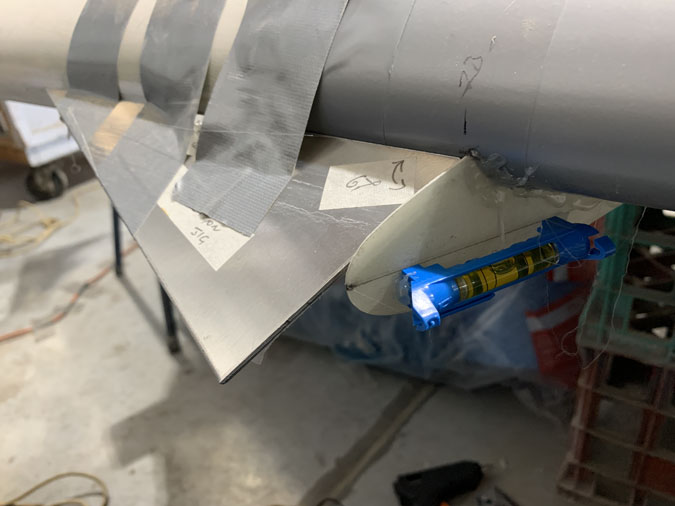

Oh boy, another exercise in herding cats. How are you meant to line everything up, hold it all in place and glass the things on? I got the wing set at zero degrees by realizing the winglets are at 60 degrees and so very easy to rig level.

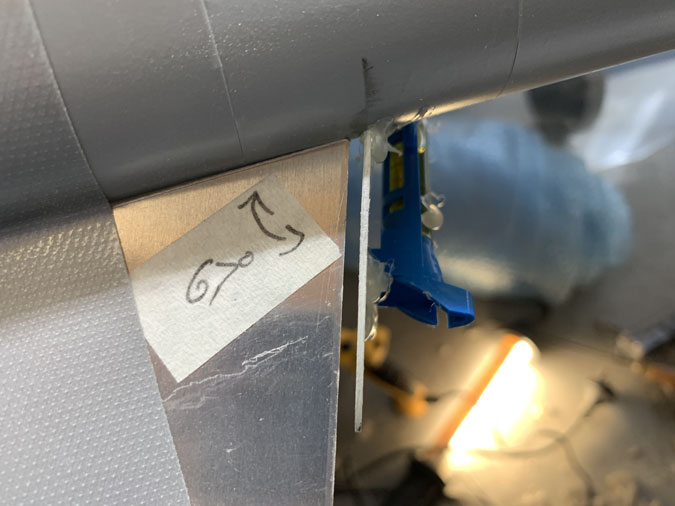

I had this idea of hot gluing the above little blue level to the centerline I’d made. Good idea but if the line is a fraction out then the bubble is WAY out, and I was really only eyeballing that line.

My process was to get that vortilon hot glued in place on one side and then glass the other. After cure I could carefully remove the glue and then do the opposite side.

Haaaa but where is that jig going? I decided it needed to be right on the center of pressure of the wing (leading edge) and parallel to it as best I could make it. Otherwise the gap you see above would not be consistent and wouldn’t have my 67 degrees.

Each side gets a two ply layup to connect it. We just need .4″ on the sides for attachment.

Once both sides are done its fun and games getting the thing off! Yes I used the usual grey release duct tape. As the nose wraps a little it is not as simple as you’d think.

After a bit I understood that the main thing is the angle to the wing. The angle of the vortilon relative to the longerons is perhaps less critical and maybe thats why it was not drawn in on the plans. It turns out if you have profiled your wings correctly and made the vortilons to plans they tend to sit in the right place anyway.

I got less anal about the waterline and found that if I used a mixing stick I would get the vortilon nice and straight. I’d made one that ended up with a bend so got to do another. <sigh>

Without the bubble level I could do three at once instead on one at a time. Much more efficient.

Now here’s a tip. When you make the two sets there is a left and right of course. They are not the same. You need to ensure that the 67 degree jig tool is on the correct side when you are setting them up. They can go either side on both wings!

So you might consider which way the vortilon is pointing when you make them. Otherwise you might have to make an extra set! That is all I’m saying on the matter, I make no admissions.

Here we have one of the six cleaned up and almost ready for paint.