| Date: 01-21-2015 | |

| Number of Hours: 10 | |

| Manual Reference: Roncz C sheet |

After much thought and exploration I’ve decided on a 2″ wide faring at the fuselage. This is to hopefully maintain attachment of the air around the sides which would otherwise have been disrupted by the elevators.

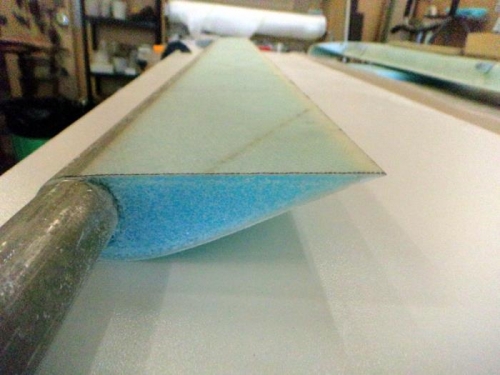

I spent quite a while working out the distances and finally marked out the elevators and did a rough trim as in pic 1. Then a very careful time with the permatgrit files working back to the lines. Once happy I cleaned off the two ply of glass from the torque tube that was exposed, another couple of hours work. Then I made flox corner ditches as you can just see in pic two, that was about 10 minutes….

The layups here would once have seemed complex but now its just fun. I slurried the blue foam, did pure epoxy on the cleaned metal and straight glass in the troughs.

Next up was my flox mix which went in nicely. Finally I’d made a template, marked out two of them on foil, wetted this out and then cut them out with my pizza cutter. Finally I applied the foiled glass, removed the backing and ensured things were down without air and not too wet. As usual paper towels came into play.

The next day after cure I cleaned up all the edges with files and sand paper. All done as you can see in pic three.

Mark and rough cut

Prep for glass

Sealed and trimmed