| Date: 11-22-2014 | |

| Number of Hours: 10 | |

| Manual Reference: Roncz B sheet |

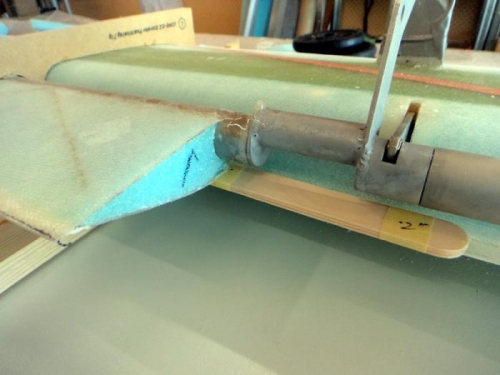

The setup was still not working out as I’d missed an important factor. I also need to ensure I have a 0.2″ gap when the elevator is in the zero position as well as the 15 degrees up and 30 degrees down shown in the plans and on the templates.

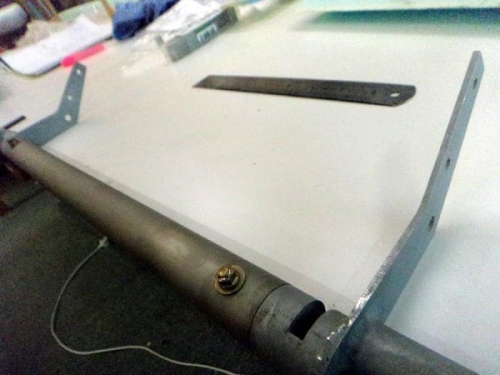

So more hours of attempted setups. The torque tube joins failed a few times so I got to play with them a little more. I did decide that the two center bolts could go in, they looked pretty easy and I was confident now that these were in the right place.

What followed was a lot of playing around practicing my drilling to ensure I was in the middle of the tube. I set this up on the drill press, something that would not be possible with the elevator to NC12 join but I wasn’t up to that one yet and still relied on the 5mt glue. I progressively opened up my two holes and it was all good. I used slightly less bolt length than plans for the AN3’s I could be within spec with thin washers. Another weight saving!

Then more elevator trail setup practice, hey it wasn’t even dark outside yet. I still wasn’t within range for the elevator movement.

Ensuring the .020″ gap

Check that gap

A little hardware in place