| Date: 05-24-2012 | |

| Number of Hours: 10 | |

| Manual Reference: 5-3 |

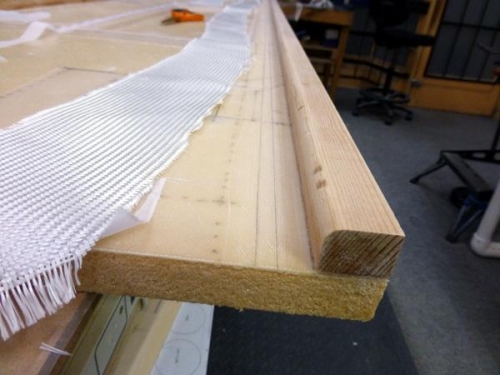

Just one ply of BID at 45 degrees bias over the entire top longerons. This was a little complex as it needed only a half inch on the side and tight bends. Peel ply was needed for some areas and I also peel plied the entire length but just at the fuselage side edge to prevent delam and any stray fibers given this is inside the cockpit.

The top longeron edge was first radiused by a fellow builder and his laminate cutter size router (I need one of these), After a clean up I prepared the glass in two pieces with the join to be hidden by the front seat.

Pieces were prepared on foil first. Then these were cut and carefully positioned on the longeron. When I was happy I removed the foil, stippled things down, trimmed the outer edge, stippled again and then added the peel ply. It took most of the day.

Top longeron shaped

BID on foil

Laid up and peel plied