| Date: 12-01-2024 | |

| Number of Hours: 0 | |

| Manual Reference: no ref |

Build start DEC 1 2011

Today is DEC 1 2024

The workshop build log now shows 16,088 hours of time over the last 13 years. This is nearly 5 hours a day for the last year, no wonder I feel a little worn out. I really pushed as hard as I could everyday to get the just delivered engine installed, the aircraft ready and first flight done before today. No so.

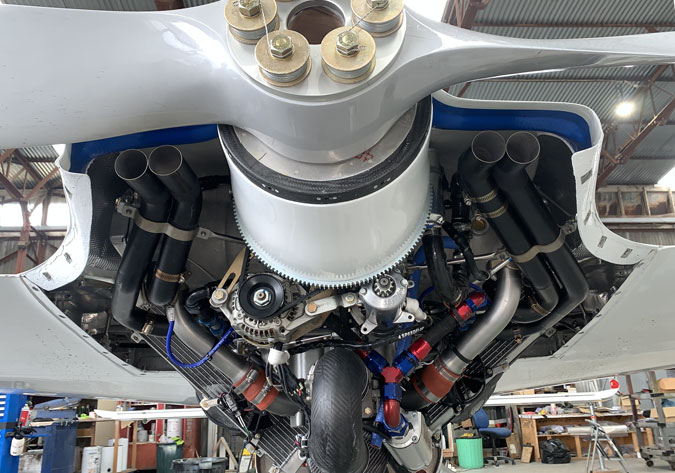

The engine is installed. It was a HUGE job. I ended up ditching the coolant related fittings I’d bought with the engine for better quality Aussie made performance car parts. The radiators were finally finished and mounted as were the coolant pumps and fans. One task seem to lead into the next as I had to find a way to fit all this ‘stuff’ under the cowls.

A lot going on here up top.

A lot going on down the bottom.

There was also a lot of wiring work under the plane and on the inside. You can see where the two water pumps ended up too. Of course the firewall titanium and fiberfrax installation was all a part of this years jobs before the engine had its ‘final’ install.

The cockpit was ‘finalised’

The panel done with all the sensors now hooked up and quite a list of other things. The last big phase of the wiring marathon. Weight and balance happened along with fuel calibration.

This is one of 5 pieces of paper which declares that I have a real airplane that is legal to be flown. That was a big day.

The cowls have been painted and other jobs that were all a much bigger job than I thought. This is nothing new. The exhaust pipes had to be repositioned to be central to the cowl openings as well, one of many tasks so near the end of the build.

The engine does run. It probably cost me around 4 months and a lot of grief to get it going after the installation was completed.

First up, the supplied flywheel did not have the magnetic timing triggers in the correct place. It took us some time and many rabbit holes to find the problem. We eventually confirmed that the magnets were moved to the right place and the sparkplugs firing correctly. The engine still wouldn’t start or run properly.

This was when ring gear teeth and starter motor gear were destroyed during our start attempts. That turned out to be a fuel mixture problem which led to significant backfires and the parts loss. In the end I replaced the lightweight Skydynamics flywheel with a more standard Superior part with the magnets preinstalled by EFII. I also replaced the BandC starter with a Skytec.

It wasn’t cranking well either. That needed the 4AWG cable replaced with 2AWG and along with a new starter that one was solved. In fact that was the only fault that was down to me and just a small delay on the journey.

This fuel/timing problem was the fuel ‘map’ that came with the engine. It was just plain wrong. Eventually a race car guy was involved and we tweaked the numbers to get the engine going. I finally obtained the map that the engine was run on in the USA test cell. That didn’t work well at all probably due to the different induction used. The next map was from the same engine as mine with the same induction and this is ‘usable’ but it will need a lot of work to get right in later testing.

I will give a big shout out to ‘Simon’ my avionics guy and friend who has been fantastic on this journey. He is well experienced in cars and airplanes and stuff with engines in general. I probably still couldn’t fix a lawn mower on my own. That said, I know more than I used to.

Here is the first taxi a month ago, Nov1st 2024, with the plane moving under its own power for the first time. Certainly a milestone, second only to first flight.

What now? I thought I’d be doing first flight before now but the engine does not cool well on the ground. This must be solved. The standard I want to achieve is 30 minutes at idle without the engine being too hot for take-off. Cooling in the air is another unknown. I am going with the idea that if it is controlled on the ground with hardly any air through the radiators, it is going to be within temperature and pressure limits for initial flights where I’ll have 100-200 knots of air blasting through the cowls.

At the moment I am gathering data in various configurations in the runup bay. From here I can make decisions and retest. It might be a long road again. Of course there is nothing to do but continue.

After 18 years and a lot of flying, JZE will be sold soon and my new ride will be ‘The Beast’, XEZ. I’m looking at just a few more flights in the old plane to retain my currency. It is time to move on.