| Date: 06-13-2018 | |

| Number of Hours: 8 | |

| Manual Reference: no ref |

The last two days have been strake prep. I spent a lot of yesterday reviewing ALL the strake notes I had from other builders and forums. I have been a little conflicted on how to do the final prep work. In the early days guys got a couple of pots of epoxy, splashed it onto the inside called it good and that worked. Maybe… Other people have done this and got fish eyes… or areas where the epoxy just sagged away and had to do a lot of sanding to fix the problem. One of our gurus says no peel ply, add more thin glass instead to support a rich layers of epoxy.

Well after consideration I’m going multiple layers of epoxy, (no more cloth), not too thick and peel ply for each layer. This is a pretty big job and I think all the peel ply will need to be cut to fit for each application. That’s 80 pieces of peel ply cut to size! Yes 240 pieces for three layers. Did I mention the sanding also required?

Oh well, quit complaining and get on with it I tell myself.

As I prepared for sanding there were still a few jobs along the way. After cutting out the upper mouse hole exits post the hat top lips, I had all these holes. My thinking is that when it comes time to flox the top on I’d have to be careful not to let any flox fall in the gaps or worse come loose and make there way around the tank for a month before trying to block off or reduce my fuel outlet.

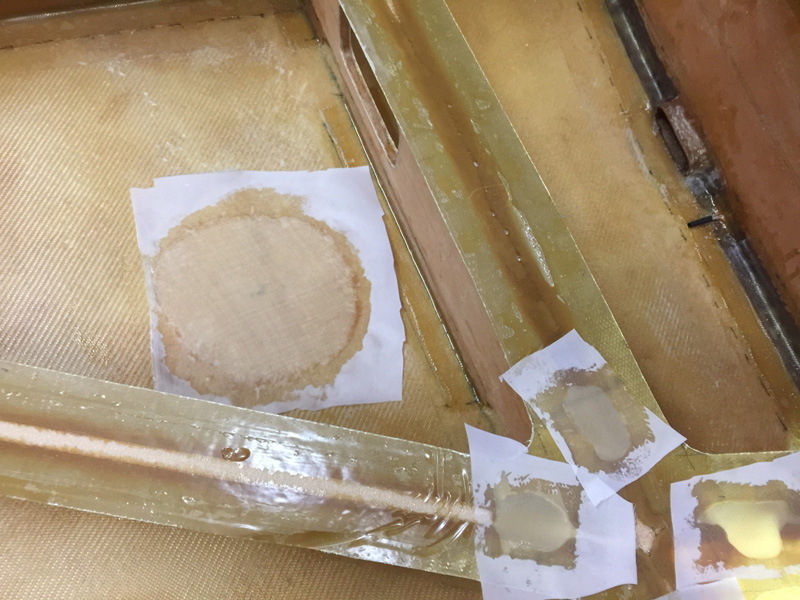

An easy answer was a single ply of BID over the holes as you see above, peel plied of course. Now I can run the flox full length without concern when that happy day arrives.

Another issue is fuel cap placement. I’ve chosen inboard and nearer the middle than plans. Yes my cap will be in the prop arc if it comes loose so I will make all reasonable provision so this will never happen. Secondly I want my cap at the high point of the tank so for the day of the Pacific Ocean crossing I can get ALL the fuel possible in the tanks. For regular filling nose down I can still get an awful lot in and can always use the nose lift to add more if the tank cap opening needs to be higher.

This all relates to that circle of cloth you see above. That’s a piece of Innegra which is tough like Kevlar but friendlier to cut and work with. You still want a WHY? OK what if some guy is fueling my plane when I’m not there supervising or even if I am and he or she sticks the fuel nozzle in too far into our 9″ deep tanks (8″ for you plans only people). Bang! It would be catastrophic if the strake was damaged so this is a little insurance for that unlikely event.

Drain hole slope. I tested what I have with water and each side just needed a little more micro in that corner as you see above. Otherwise the drain is working very well. I will test again before closing the strakes.

Now to the sanding. I’m using that trouble light, a vibration sander and 80 grit sand paper. While I’m not going for 100% matt I am wanting say 80% non shinny before applying the first lot of epoxy inside coating. Its not like a structural bond where 100% is necessary. I’m doing this to fill in possible pin holes and as a way of going over the glass work and treating any air bubbles or anything else I find. Someone said you need your best work here, so its extra effort. I do not want to be fixing leaks! I’ll do my reasonable best and see how it goes.

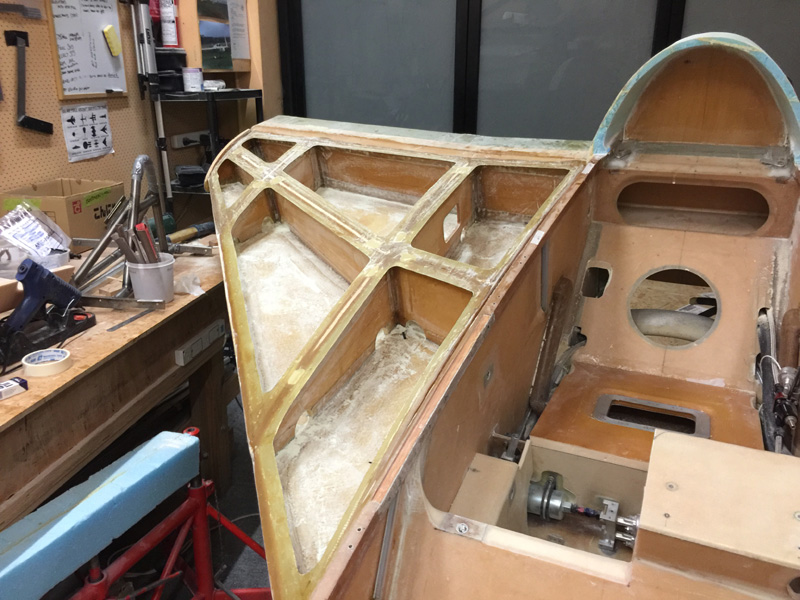

Right side just about sanded.

Left side just about sanded.

Both sides just about sanded. I liked this picture so bloggers rights to include it. More sanding and clean up tomorrow and I’ll make a start with the peel ply and lay down some epoxy. I have 12 compartments to do per side and I’ll just go in stages with small batches.