| Date: 04-16-2018 | |

| Number of Hours: 8 | |

| Manual Reference: no ref |

The upper section of the strake shelf was next.

I again very carefully hot glued the conduit to the curved line of the strakes drawn on the sides. The top section curves away so I needed to hold the conduit horizontal. This way I’d get a shelf at the right angles. It just took a little longer than the bottom but it wasn’t difficult at all.

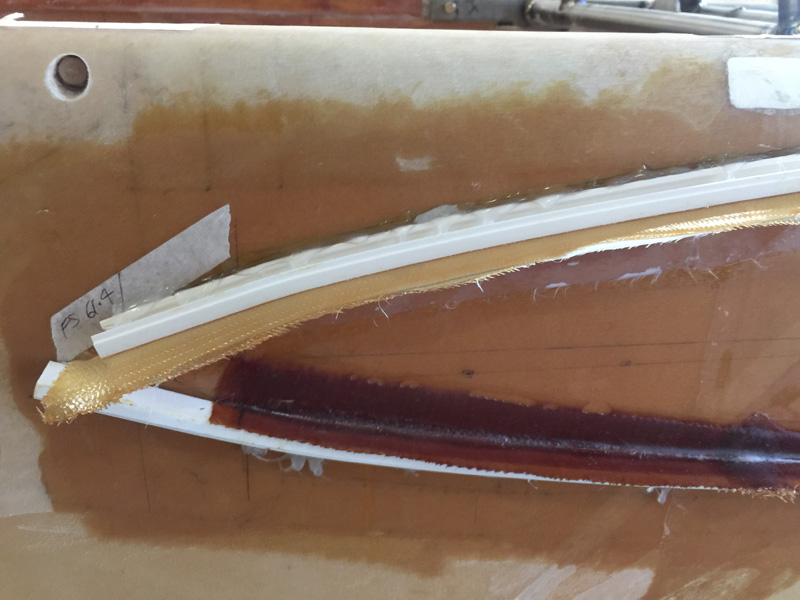

You can see we get a really nice even curve with this method.

I prepared the 3 ply of BID on foil as usual. It was a bit more challenging upside down but it did stick there.

Amazing how the epoxy will let you work inverted. I peel plied as usual with two strips so that the inside corner was not compromised.

This is after the cure and a bit of sanding to clean it all up. The plastic conduit came off easily and I have an excellent ‘shelf’ made from glass and fuel safe epoxy.

This gives a feel for the strake shape. Not at all like the plans flat top.