| Date: 12-29-2024 | |

| Number of Hours: 3 | |

| Manual Reference: no ref |

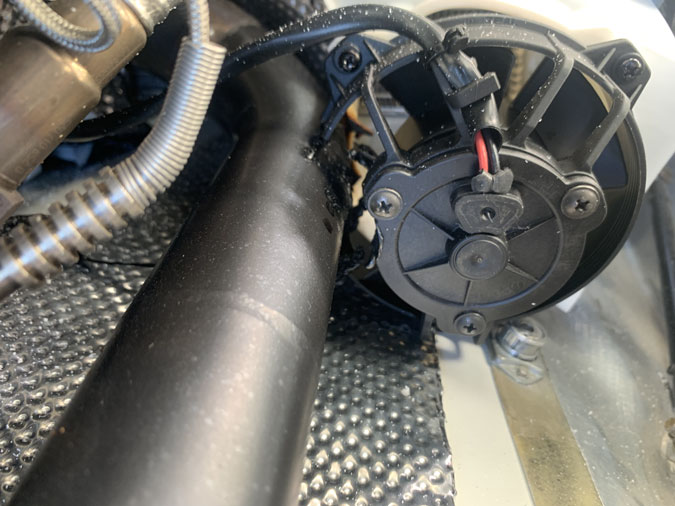

I used a lot of gaffer tape and spare heat shield material to secure the fans and shrouds for the next test.

You can see the fans really tightly in place. Its just a quick test and gaffer tape works on everything. I think they have some on the ISS (International Space Station).

Here’s a bit of a walkaround before I headed off to the runup bay for testing.

It turns out that gaffer doesn’t work that well when things get a bit hot. Goodbye expensive fan. 🙁

In fact I should have pulled the pin earlier.

After I shut down the engine and coolant pressure continued to rise. At 18psi it will blow the cap, or rather the bypass valve in the radiator cap with operate to send coolant from the expansion tank into the overflow bottle. I saw a bigger number than 18psi in the data.

If its still too hot, that overflow bottle will fill up and as a last resort it has a little hole in the cap.

My expensive 3D shrouds are not what they used to be. See item #6

A few lessons learnt.

1. If the test is showing high temperatures, just abort early.

2. Minimise the under cowl testing temperatures, I might be stressing wiring and other components.

3. Reduce the time in the idle, I REALLY don’t want to glaze the cylinders.

4. I need to reduce all this taxi time, so only necessary tests and finger crossed about the glazing.

5. I need to do better than gaffer for securing heavy fans onto radiators in high heat conditions.

6. 3D printed parts with cheap plastic are NOT heat resistant.

Ahh but I won’t be put off easily. Here we have another set of shrouds again nicely printed. The data from the last test was not useful because of the shroud failure. I want to know do these fans and heat shrouds work??

This time I got excited with foil tape, lots of heat shielding, cable ties and even lockwire.

Here’s a bit of a look around. Off I went to the runup bay again full of hope and good cheer.

The fans did sort of stay in place but the shrouds were again heat ‘effected’. I could use them again but its not a 100% seal. At least I got some data.

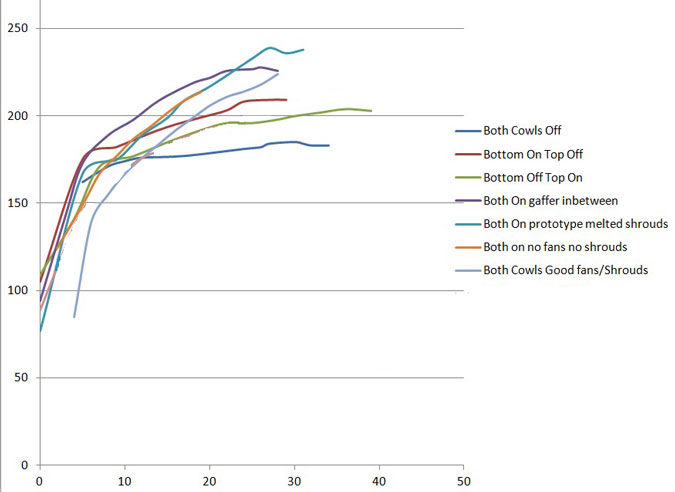

Yes my chart skills have improved. You can see Both Cowls on with melted shrouds and Both Cowls no fans is pretty much the same temperature. I want to be around 200F for take off so I have a bit of margin when the aircraft goes from idle rpm to full power. Its going to get hot, fast. I will test this in the runup bay and/or on the runway before first flight. I don’t want a boil over after two minutes!

The numbers we want to compare at ‘Both on no fans no shrouds” (orange) with “Both Cowls Good fans/Shrouds” (light bluish) The fans and shrouds give me only about 10F improvement and maybe 5 minutes before we get to the 200F at the 15 minute mark.

This tells me the whole fan shroud thing is doing very little really and given I want twice that time before takeoff and still be around 200F, I am nowhere near my design goal.

CONCLUSION: I need cowl flaps on the bottom cowl and maybe on the top too. I do want to confirm after getting the bottom cowl with cutouts for flaps tested with and then without the fans. With hot air escaping I would then find out if the whole fan/shroud thing is worth the trouble. I suspect not, but data is king.

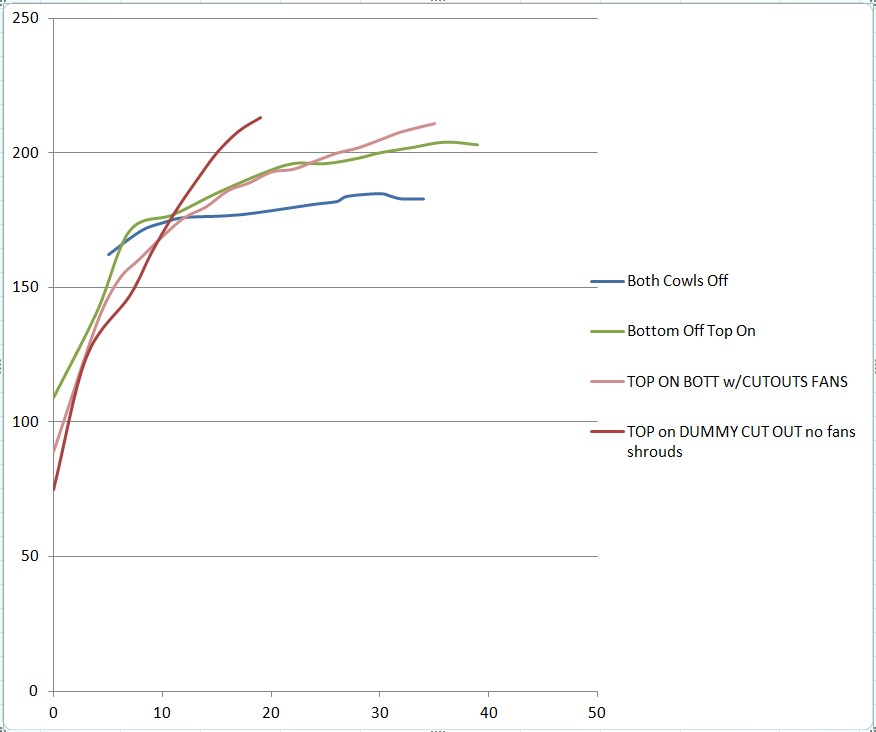

CONCLUSION UPDATE: But wait, its 1/1/25 and I did the test with the cowl cut outs and NO fans. I was completely surprised. The fans, now that there is a path for the hot air to escape do a huge amount of work unlike before the opening. At just under 20 minutes with fans 189F and without fans 221F and rising fast! That’s 32F difference. The oil was 200 vs 213 without fans again at only 20 minutes.

I did remove the fans for this last test and they are looking quite melted and sad. I am going to have to do the next set in Carbon fiber as a hand layup, the plastic is a big fail. I’ll get more of these printed in something I can use for a mold so at least it will give me a shape to work with.

It looks like I am going to need those fans and shrouds after all which is disappointing. The plan is to now go ahead with a dummy top cowl and do similar cut outs. I’ll have to make doors for them of course and get that all working in the mock up. I will then test again, with and without fans and shrouds and make a final decision. At this stage it looks like the fans are back in the mix again unfortunately. The doors and going to be very tricky to get working so that’s my January 2025 already planned out.