| Date: 12-02-2024 | |

| Number of Hours: 6 | |

| Manual Reference: no ref |

Identify Goals

The plane is almost ready for first flight. I have now done 11 taxi tests. It steers well at low speed , and we have ironed out a few small avionics issues. I still have a radio problem to solve. I’m really liking the bigger cockpit than my usual Long-EZ and the improved visibility.

All seemed ready for a fast taxi text except for one thing. It just gets too hot on the ground. My design brief is at least 30 minutes at idle revs with the engine not too hot for take off. Ideally it would never get too hot just sitting still but I’ll settle for 30 or 40 minutes as realistic behind a few Boeings and Airbus size planes in a queue. It may happen, I don’t need to wait for that scenario to sort out the issue.

If I flew now, and even if it was great cooling in flight, I’d still have the ground problem. I fixed that ground cooling later it might then not be OK in the air. This would make a first flight now, well, not useful. This time we have to go in order, fix the ground cooling issue, then first flights.

Identity the Cause

What is the problem exactly caused by? That’s easy, I have almost no air going through the radiators. Once flying there will be 100-200 knots of air roaring through them, in the taxi almost nothing! The prop on a regular plane pushes air through the cowls and cools the engine, on a pusher it does nothing you can notice.

Isolate the Issue and Collect Data

This was a series of four ground tests in the runup bay each from 30 to 40 minutes duration. I wrote down data at the time and also have real information collected every second by the avionics and recorded on an SD card.

I had install 2 X 5.2″ fans on the back of one radiator and one 5.2″ fan on the other. I had tested and found reverse flow or rather my smart avionics guy noticed it. He may read this so I’d better not take the credit. The fix was some gaffer tape. Now I have three fans flush to the back of the radiators covering 71sq” out of 207sq”. I’d also done one runup to 2300rpm while standing on the brakes. Wow did it get hot fast then! Usually I am sitting at about 860rpm which was the number I used for these four focused data collection tests.

Test 1 Cowls Off

Test 2 Top Cowl OFF Bottom ON

Test 3 Top Cowl ON, Bottom Cowl OFF

Test 4 Both Cowls ON

Simple Data Analysis

Simple Data Analysis

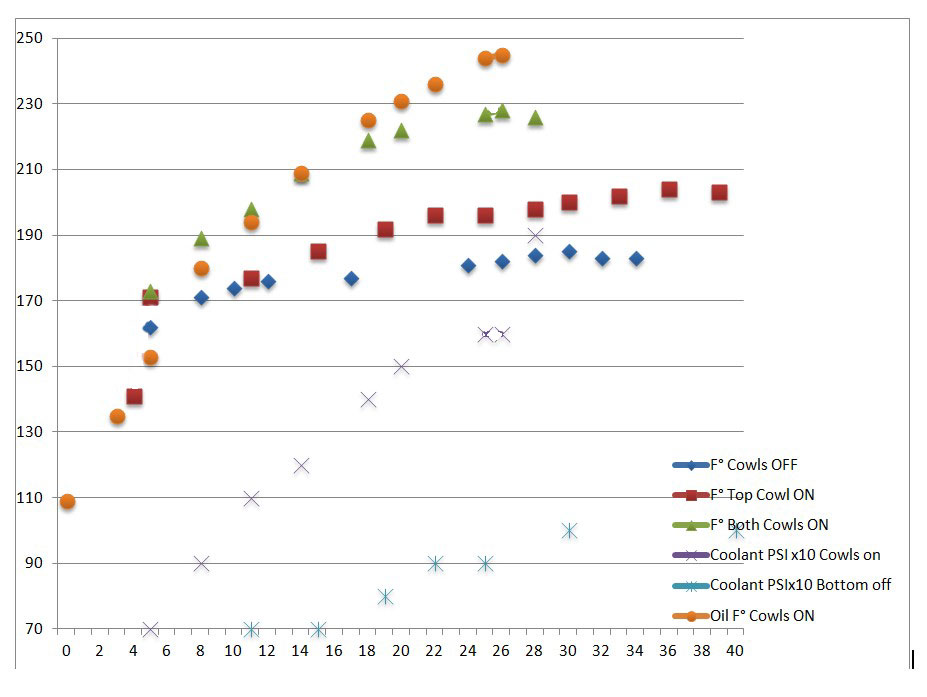

I’ll spare you the ton of information and just show this rough chart I drew up. Time is on the bottom 0 to 40 minutes and temperature in F° from 70° to 250° With a 1.4 bar cap (20psi) and the coolant in a 50:50 mix it will boil at around 250F°

You can see with both cowls, the green triangles, I’m heading straight for this maximum at the 28 minute mark and the oil, the tan dots, is getting close to maximum as well. In reality if I went to take off and raised the rpm from 860 to 2300-2500rpm the coolant would boil, probably before I left the runway.

Coolant pressure got to 19 psi with both cowls on. 20psi will blow the cap and overflow the coolant. Not good. Bottom cowl off and it got to only 10psi for the same time period. A huge difference.

Both cowls off, the dark blue, and life is good. Except I need the cowls on the plane for drag reduction! Top cowl on bottom off and I would be close to maximum temperatures at takeoff but its looking like possible if I could ‘vent’ the lower cowl and then seal it up again. They call these things cowl flaps. BUT wait! There is another issue.

Delta T

This is the difference between the coolant temperature coming straight out of the engine and the temperature after the pumps, radiators and the heat exchanger just before it returns to the engine. I haven’t shown the collected numbers but overall its around 6F° in flight it should be nearer 14 -16C°!!! So the first thing to address is the fact that the cooling system is not effective with the fans going. It should be better than this.

Possible Solutions

First I need to make the fans more effective and then test again. If cooling is still not good enough then some sort of cowl flap or vent system, probably in the lower cowl based on the testing, will be needed.

I’ll show you what we have been up to in the next post getting the fans to do a better job and how I have begun to set up a way to trial cowl openings without destroying my existing cowls. .