| Date: 09-29-2015 | |

| Number of Hours: 10 | |

| Manual Reference: HP Rudder R1 |

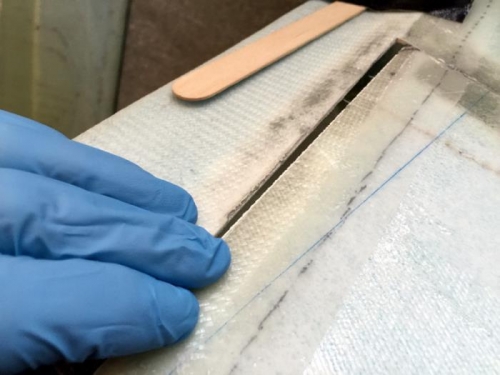

Over a few days I first cleaned up all the edges and had a good fit for the rudders. I soon found a problem, not completely unexpected, in opening as you see in pic 2. I chose to make the rudder top and bottom cuts in line with the airflow rather than at right angles to the hinge line per plans.

This means that as the rudder opens it scrapes at the rear end on the lower winglet. It took a bit of thinking to find a solution. I knew there was one as I’ve seen this configuration on another EZ. Going the route with the least work I have cut back one edge of the lower part of the rudder as you see in pic 3. The gap is what I will address later.

I’ll have to add some glass to one side of the lower winglet. It will work out well. I’ll wait until the rudders are on and hinges set in place before doing this so I get the optimum close out. I’m not sure if I also need to adjust the top of the rudder in the same way. There needs to be about 1/8″ clearance so we will see later what is needed.

I have to add how much I like just holding these rudder and working with them. They are amazingly light and strong. That said it has been a real bear and many hours are going into sorting out this part of the build.

Trimmed to fit

An opening issue

An offset solution