| Date: 01-15-2018 | |

| Number of Hours: 12 | |

| Manual Reference: 18-5 |

The task was just to get the inside of the turtleback foam down to 0.5″ and lay it up with one ply of BID, internally. A quick three days work.

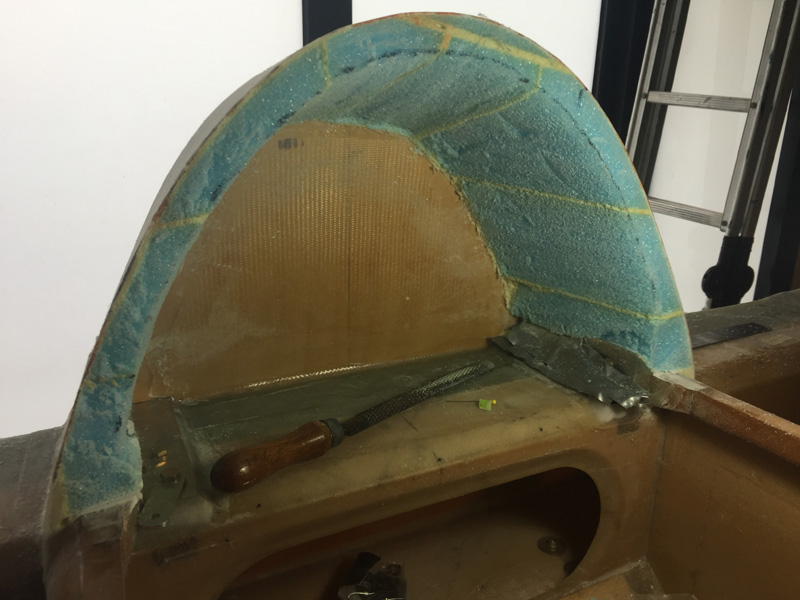

You can see above there is a bit of shaping to be done.

I used a hat pin as a depth gauge as you can see in the pic.

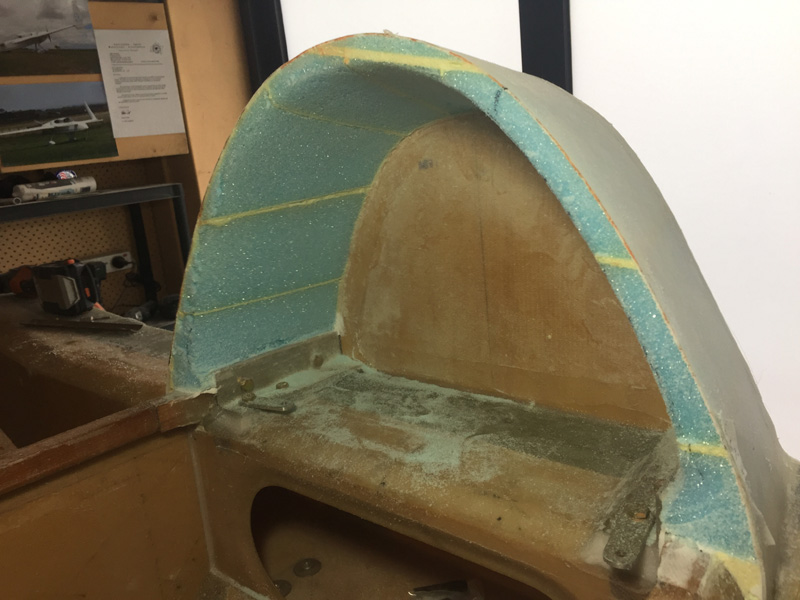

It took quite a while because I had to dremel the yellow glue joins down below the blue foam to get even sanding.

I went for .7″ rather than .5″. For the very minor extra weight I think it is worth it for a stronger rollover here. If the plane is ever inverted this will be where the weight is partly taken.

I pondered for some on this inside ply of BID. It would be much easier to do it if the fuselage was upside down. I decided that was too much trouble. I wetted out the cloth above and the inside of the turtleback with pure epoxy. Then I waited nearly an hour so it was just a little sticky.

Here we are after the peel ply. It worked out OK but was a little challenging.

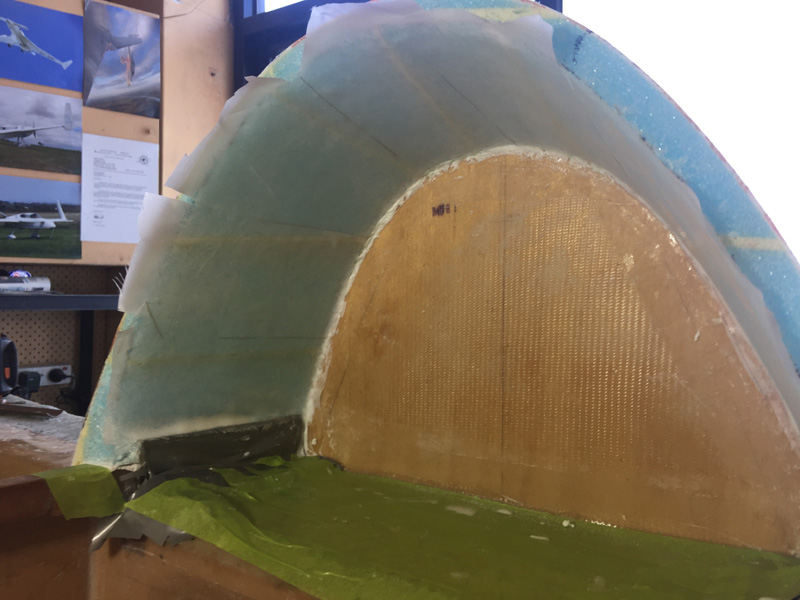

The next day I prepared a BID tape to lock the inside of the turtleback onto the firewall. Plans have you do this with the single ply in one step. I could see it not working out as well, so went the two stage method.

That’s it for now, nicely trimmed and the tape at the back. I’m not sure how I’ll do the lip but it is advanced enough to keep going. I want to get the canopy on the hinges first. The turtleback despite only one internal ply feels really strong.