| Date: 02-05-2024 | |

| Number of Hours: 6 | |

| Manual Reference: 23 |

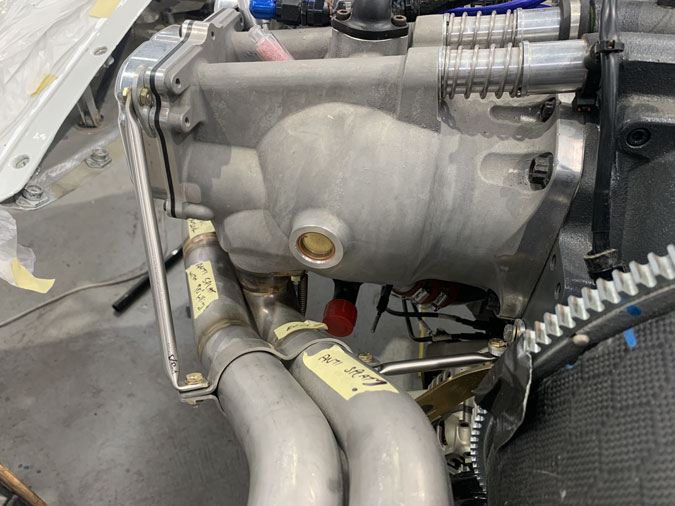

Here we go for the almost final securing of these exhaust pipes.

I wasn’t happy with the movement with just two stays so it had to be a third one. You can see the triangle shapes so it has to be secured right? …and it is now rock solid. We do have just a tiny bit of wiggle left and thats what you want to prevent the pipes from cracking. Maybe I’m wrong and they can flop around more. The amateur engineer in me just didn’t like it.

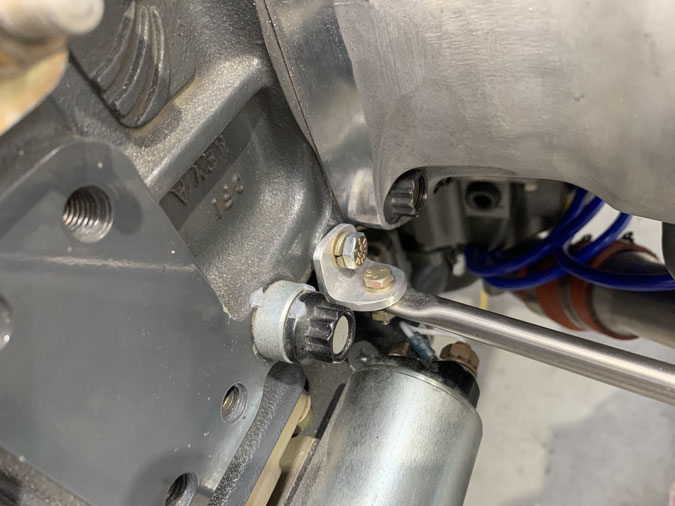

I’ve tidied up the fittings a little. I’m sure they will come off and on a number of time yet. I am still waiting on the new machined shoulder bolts but the old ones are fine for getting things in place.

I did have to make a new bracket just another hole width towards the outside now I have two stays on the same fitting. The nut is pretty close to the injector but they are NOT going to touch, both are very rigid in place.

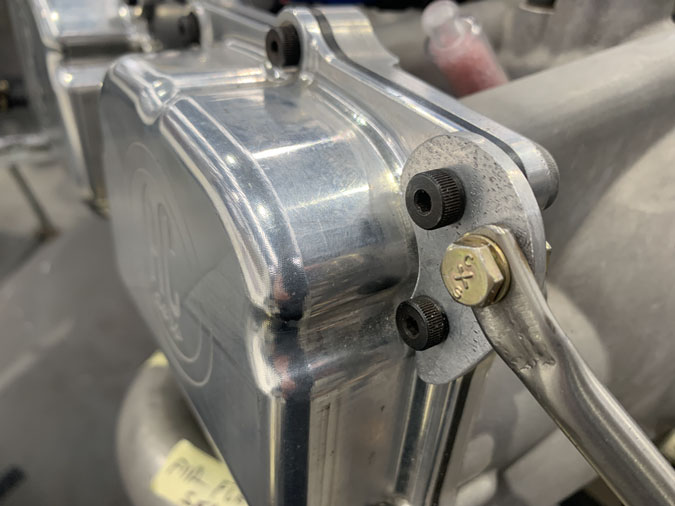

I hope I won’t see any cracking with these angles. If I do I’ll convert to angle fittings and an extra fastener set. This stainless is very strong, it should be OK as is.

Now over to the left hand side where I had just one stay. I’ve added a new rocker cover plate and one more upright stay that was a bit tricky angle wise.

The engine case fitting has been tidied up.

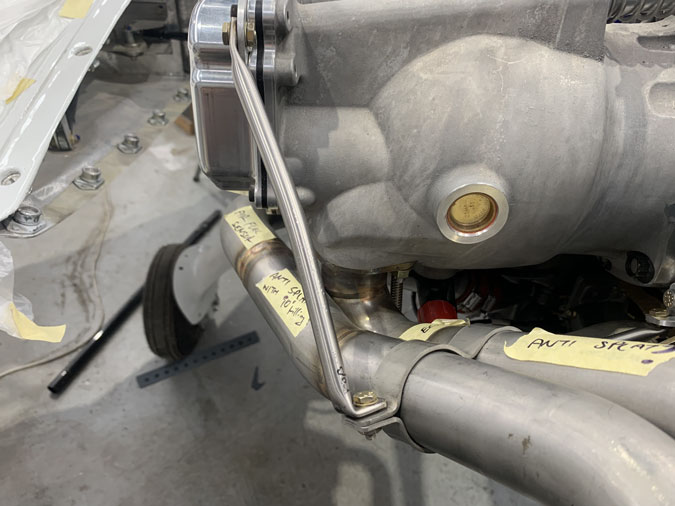

This bend is no accident. I wanted the angles correct so the hold on the pipes was ‘relaxed’. It took a bit of doing. It is attached to the outside at the top as I have minimal clearances on the inside of that bracket…without making a bigger bracket.

Its pretty small and tidy here on the rocker cover plate.

Overall I’ve never seen stays on the end of the exhausts on a 4 pipe Long-EZ as I have here. Well I make no excuses, this is what this particular build needed. Most people seem to bracket or secure the pipes off the air cooling baffling. I don’t have any of that stuff given that this is a liquid cooled beast.