| Date: 02-04-2024 | |

| Number of Hours: 12 | |

| Manual Reference: 23 |

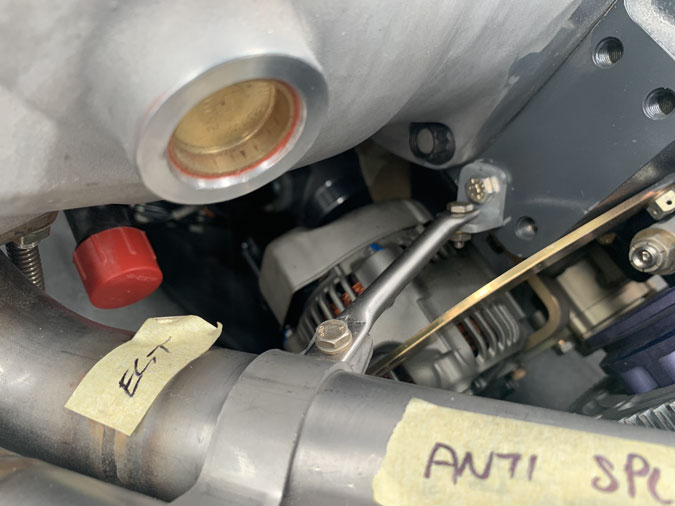

My exhaust ends move excessively. They have slip joints at the engine but of course they need securing at the ends as well. I took a video of the movement and sent it to the exhaust manufacturer. He replied that this is normal but I also need to stop lateral movement. He suggested something that attaches to one of the rocker covers.

Easier said than done.

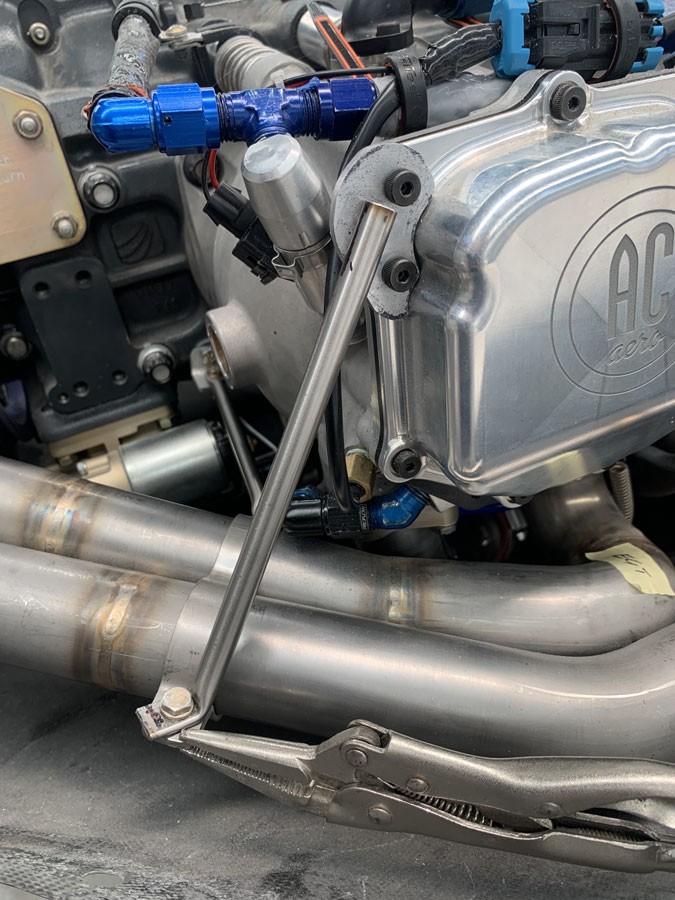

Hers the first support I made. As much a poof of concept as anything else. Its about 10mm diameter stainless steel pipe with the ends squashed to make a fixing point.

This is closer up and its working quite well. It has stopped the side to side movement but we still have a lot of up and down.

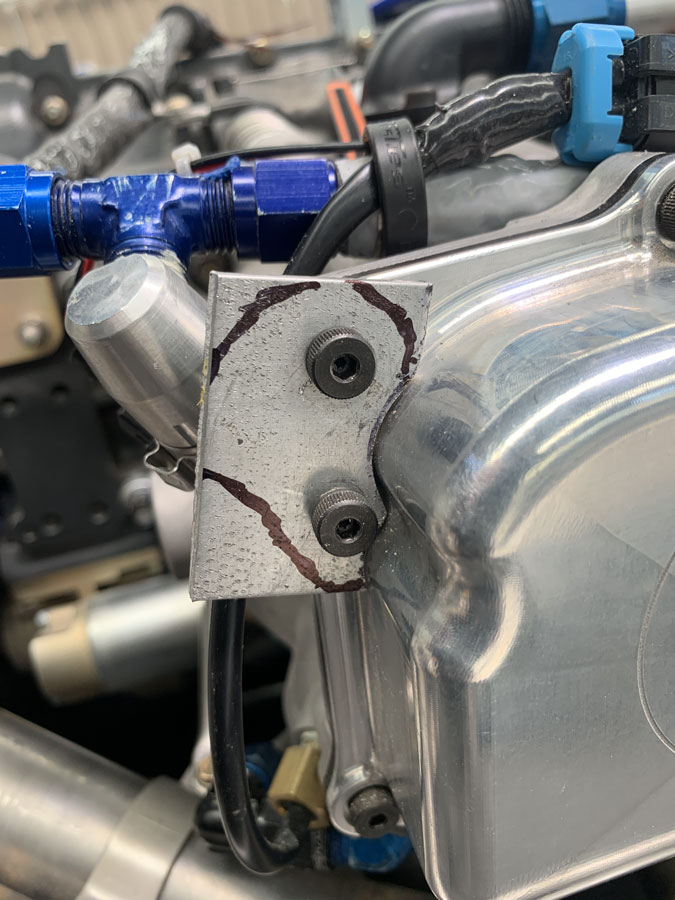

These weird things are ‘shoulder bolts’. I need ones with a longer shoulder to fix a plate onto that cover. I spent some time online and ordered what I though were the right ones and then waited a few days. What arrived were long enough BUT the thread was smaller. I thought I had it right. I ended up going to a specialist bolt place in person to discover the size I want is unavailable in Australia. Great…

I did buy the correct thread and shoulder length, its just that the shoulders are too wide. The very skilled machinist at the hangar is going to make the required adjustments. My $2 bolts are going to cost a bit more now. The up side is that I can keep working even if the old bolts don’t engage fully.

It took a bit of work and two tries to get this plate to fit.

After a clean up it looks better. The connecting support pipe also took a couple of tries. I was going to use a 90 degree bracket but it was a problem getting something in stainless, I have plenty of angle in aluminium. I don’t see that dissimilar metals here at the hot end is a great idea. The rocker covers are aluminium so nothing is ideal.

Here we are all in place. It is better but I’m still not happy. There is a bit of up and down movement despite the two supports. Given we have a slip joint at the engine end I think this opposite end of the pipes should be super solid. It looks like I am going to need a third arm onto the plate. Depending on what interference that has, I may have to move the pipe bracket down and inch or so. This would mean I have to remake the two existing brackets a little longer. The ones that I just finished today. So be it.

Meanwhile on the left side I just have one bracket at the moment. I’ll have to make a similar rocker cover attachment plate and hang from that for the second ‘arm’. This side is shorter due to the offset cylinders and the pipes have far less movement. I may be OK with just one more bit of stainless rod here. I’ll just make one and give it a try. Experimental aviation is all about the wiggle sometimes.