| Date: 06-10-2019 | |

| Number of Hours: 16 | |

| Manual Reference: no ref |

Over this last week I’ve been sorting out this RAM air and hellhole cover while still sanding and filling the underside of the strakes. Thats the gift that keeps on giving.

I felt the sides of the ram scoop at the base were not strong enough to hold the hardware so this received another 3 plies a side. I had previously glassed over the ‘scoop to base’ edges as well.

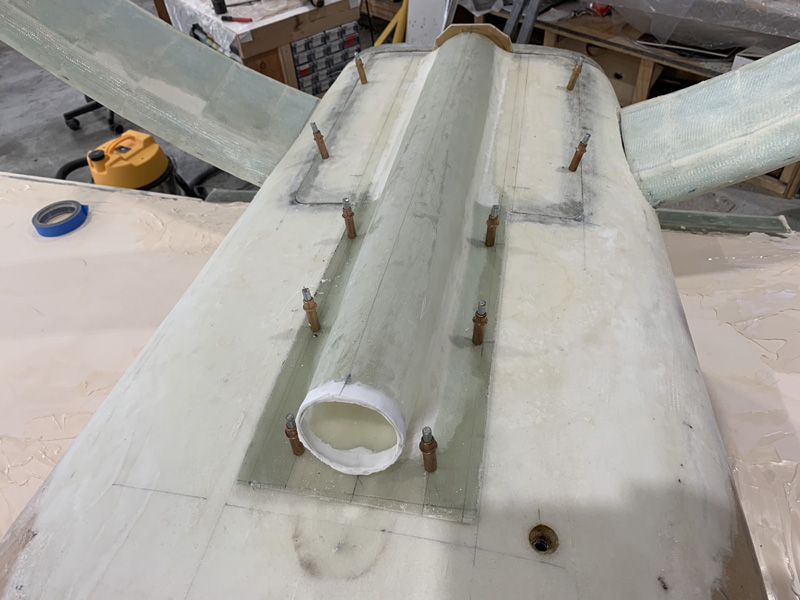

After quite some thought I positioned where the fasteners had to go and clicoed the scoop in place. All was good.

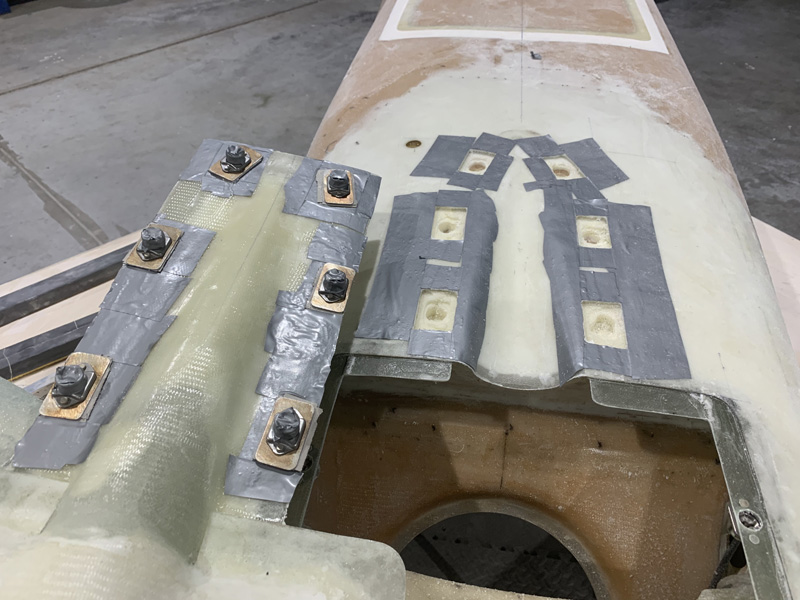

Next up the process of making the nutplates you see above, I have an alodine pen as well which was an easy way to get a coating done. I did roughen the plate surfaces as they will be bonded to glass and micro. I used a router and cut the position slots by hand. Then it was a little more time positing the scoop to ensure I had the foam receiver spots in the fuselage big enough.

First up was to micro in the Camloc receivers so to ensure I could get the scoop off after the cure.

Once the top was off, I added a little more micro around the nutplate edges and then two plies of glass and peel ply. These are not going anywhere now.

The scoop and hatch top assembly could now get a little tidy up. You might notice I have a bell mouth entry made for the narrower end of the scoop. I’m told this will assist airflow.

In place with the Camlocs positioned. They will get a final fit after the filler is done.

I do have a bit of a lip to blend in from the top. I could have easily made a joggle but didn’t think of it. That would have been better than having to fill and fair in a more ‘fulsome’ way. If you are about to build a scoop and reading this, I’m sure you will do better. There is still a fairing to build on the cowl bottom before I trim the end of the firewall. We are pretty close to having this scoop and lid all done.