| Date: 06-02-2019 | |

| Number of Hours: 15 | |

| Manual Reference: no ref |

Over the last few days the scoop plan is coming together.

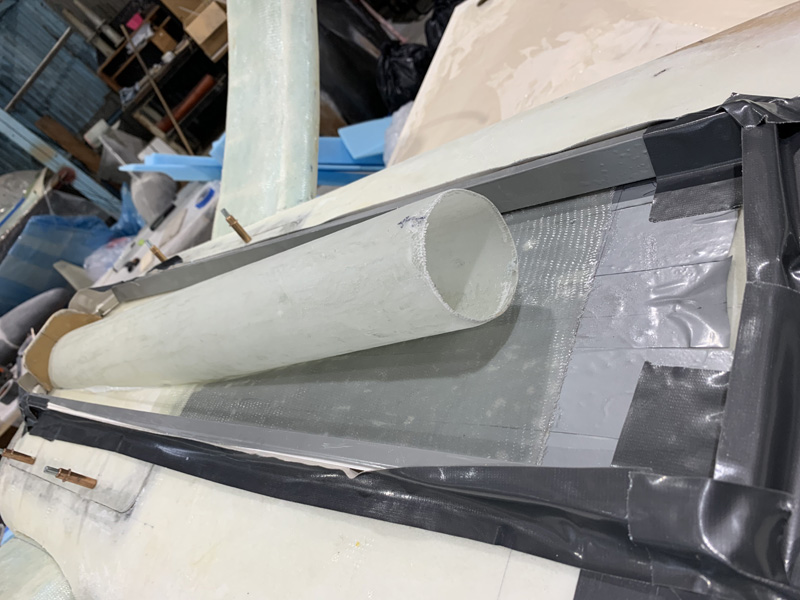

Given the scoop is now microed in place onto the hatch cover, I now needed a base to build the fairing onto. This base has to join to the hatch but not to the bottom of the fuselage. I went for two ply of BID and the usual grey duct tape for release.

I then got creative with the idea that if I introduced the pour foam while the glass base was wet something good would happen. Yes the foam as it expanded would push the glass onto the base of the fuselage and reduce the air gap that may have happened otherwise.

As it turns out this worked about 80% but I had several hours of getting the newly made cover base released from the fuselage. It came off eventually with no damage.

This seemed like a good time to trim the inside foam of the hatch lid to something more manageable. When this was done I gave it a coat of micro to act as a hard shell for when I glass this underside.

Yes while all this was happening and I have also been doing the fill and sanding of the stakes. Another need was to make a lip for the scoop to seal against. The initial layup was done from under the plane through the hellhole. Not ideal. I’ve followed up with a three ply reinforcement as you see above. The fit is excellent.

More time in blending all that pour foam into a minimal side fairing.

Once shaped I have again gone for the micro hardshell method. I’ve added a little meat to the entry point as well, I want to make an optimal edge here.

This is a side view to show the angle of the scoop to the fuselage bottom. Its a compromise of the 2 degrees nose up fast cruise angle, climb angle and minimum wetted area for the fairing to cowl intersection.