| Date: 04-05-2019 | |

| Number of Hours: 16 | |

| Manual Reference: 16-7 |

This is really a modification. Instead of the plans bellcranks and pulleys for the rudder cables I am going from the fuselage straight through to ‘present’ to the wing. This has been long planned without knowing exactly how.

After many many days thinking and looking I finally got my long drills out and made a hole each side. I’m partly in the longeron, then skimming the top of the spar without penetrating it and out the other side.

Having the Melvill cowls meant I had to make a faring and this turned out to be a great place to get the rudder cable conduit through.

I dug out a bit of the pour foam to make a place to get the cable through. Now I realised its best to get the tubing sitting right on top of the spar. I may need to add some cooling air here so I like knowing I have this option with no ‘cable in a tube’ in the way.

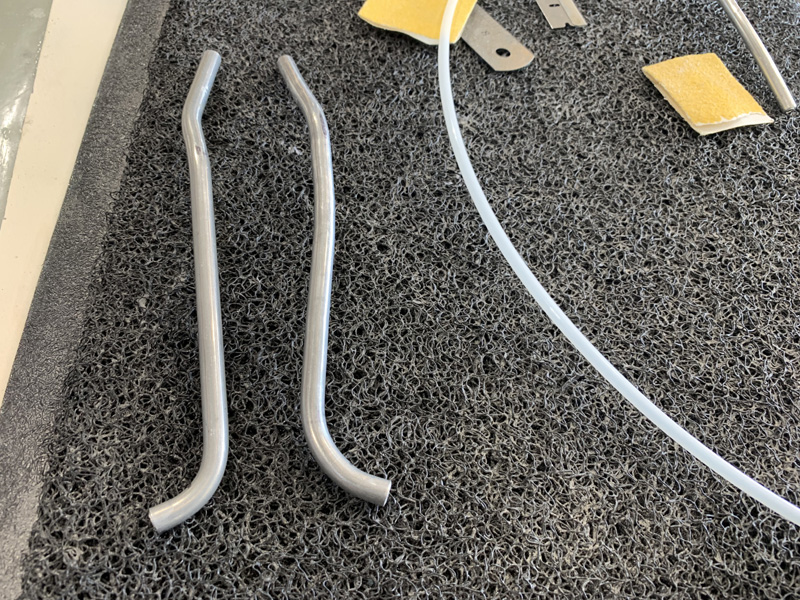

I used some soft 3000 series tube to make a ‘model’. Then this is in 2024 T3 left over from the canopy controls. The tube is the perfect size to contain the nylaflow inside it.

This is roughly where the pipe will go and then pointing directly at the wing cable exit. You might notice I’ve really cleaned out a lot of the pour foam. I initially left it as I felt it was adding strength in case I rested on the bulge during maintenance. It is very strong with very little foam, so who needs the extra weight?

I tested earlier with a bit of tube and the cable slides perfectly around the corner with very little resistance.

After a LOT of work and checking I finally floxed the ‘outer’ tubes in place.

I added a piece of BID (2 plies) so there will be plenty of strength for when I introduce the nylaflow into this area.

A few words on those AN111-4 fittings. I found that if you swage it up close and tight it looks like it would be a lot of strain on the cable turning so sharply.

I found that about this much slack works out pretty well once you get the nicopress tool on it.

This is still very secure but I believe not as much strain on the cable. Just my own idea, I’m not a cable guy. It just seems common sense.

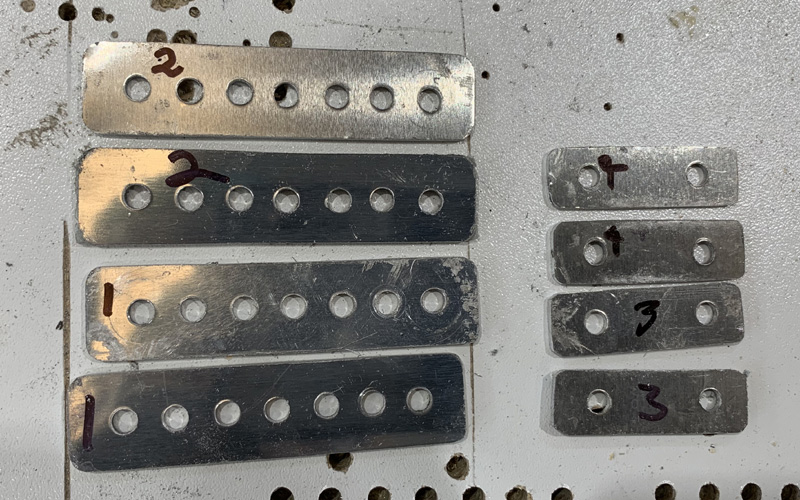

While I was endlessly working on the cables I made up a set of quick release joiners and a set of rudder position cable length adjusters. 2024 T-3 and .063″

Although without the nylaflow in the tube yet you can see that the fitting is well clear of the upper cowl line. I might add I’ll be changing the fuselage side fitting to the AN111. I think I need 8″ of cable slack to get the rudders off without cutting the cable each time. There is very little margin here.

I have the idea that this would be a great place to put the cable length adjusters INSTEAD of the smaller quick release. This makes more room up front where the special double direction spring has to go. If I go with this I will have to redo all the cables and make the adjusters shorter. Shorter adjusters is kinda not the point! So I’m still thinking on this one.

Having done all this work with the plans 1/16″ SS (stainless steel), I am now told by real ‘experts’ that I should have used galvanized 1/16″ cable instead. I’m nearly convinced, so I just might trash all the work and go again. It will be very quick now I’ve sorted out the problems.

Another issue is that I’m unhappy with my rudder pedal position. I have plans measurements but they are not as comfortable as my flying Long-EZ, so I’ll be looking at sorting this out. Maximum comfort to reduce fatigue is very important on this build.