| Date: 09-16-2022 | |

| Number of Hours: 15 | |

| Manual Reference: no ref |

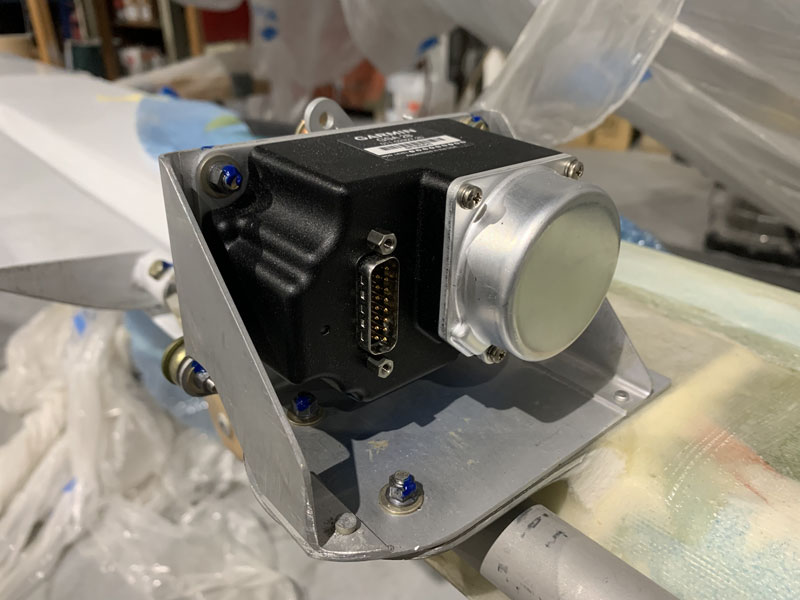

Its September 2022 and I’m still waiting on the engine. It is time to do some ‘final’ set up work on various systems. Here I spent hours on the canard and put the servos back in. Both Garmin servos have been replaced as they were faulty from day one. We didn’t find out until we hooked it all up to the installed avionics. The warranty goes from the purchase date, not the installed date on ‘experimentals’. Certified purchases get warranty on THE SAME item from the installed date. Hmmm.

I ended up paying a relatively minor amount after much ‘discussion’. Now Garmin will replace any servos as so many have been showing up faulty. They will be fixing their production issues I’m told.

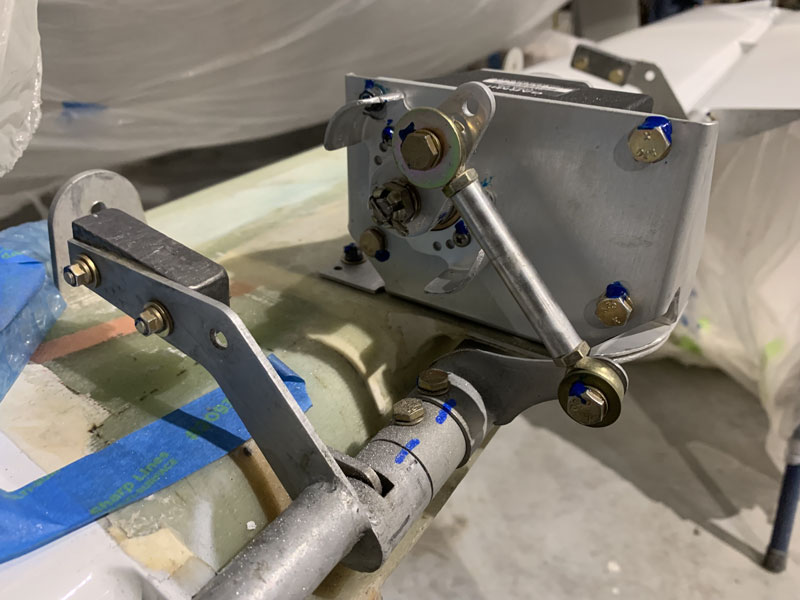

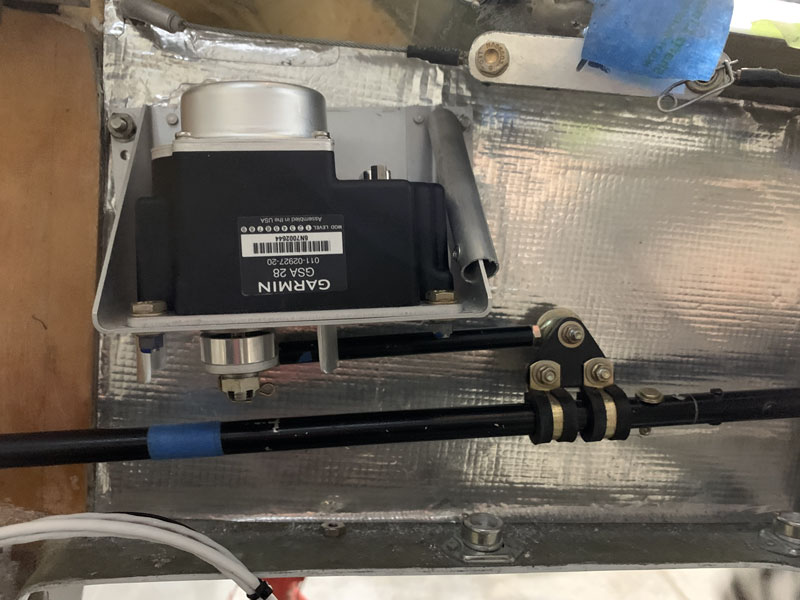

The pitch servo now in place. The blue torque seal is a ‘code’ to say ‘I have done this bolt and nut up to spec’. The idea is that when i am ready for inspection I’ll know what needs to be tightened or checked and what has already been done.

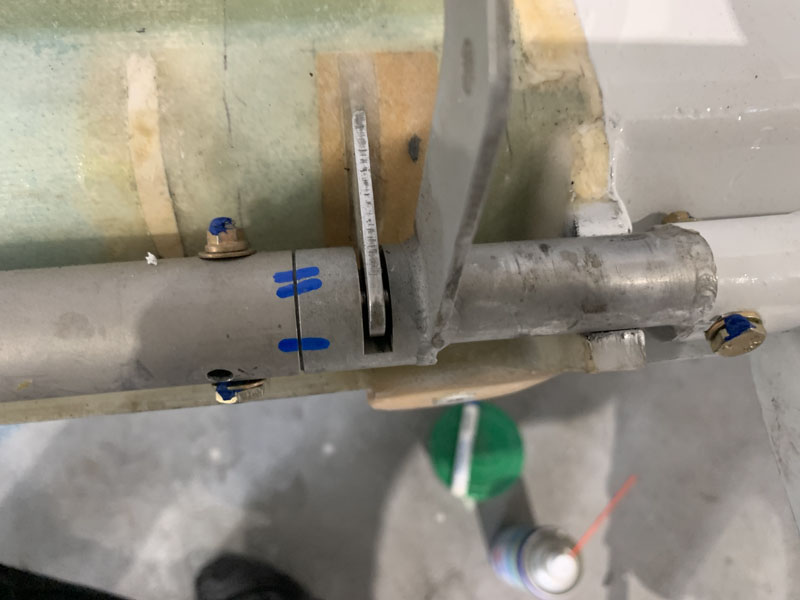

The blue lines on the tubes are in case I have to disassemble them so I can get things back to the same place without a lot of refitting. This setup with the arm ensure it can not lock over center. Its on the inner bolt hole of the arm according to other canard flyers who say this is the best place.

I had to tweak the hard stops for the servo which guard against runaway. There is a very wide throw in both directions on this elevator system. In flight with JZE I use very little of it.

I had these apart a while ago and it was very easy to put bolts in different holes. The problem is everything nearly works…but not quite. The blue paint lines should help if they have to come apart in the future.

There is some friction in this elevator system that I am not happy about. It might make no difference.. or maybe it will. The fix is to reduce the excellent fit of the phenolic runners. That’s where its grabbing slightly. To do that I need to get the hinge pins out…again. Its a horrible frustrating and difficult job. Did I mention, horrible.

Ok I am thinking about doing the fix… or maybe see if it is in fact a problem during test flying. It will either feel a little stiff or not be noticeable at all. It will not be a safety of flight thing. it MIGHT be an issue near the onset of flutter. I don’t know… so I’m seeking advice.

Good access for the nuts here.

This is the roll servo

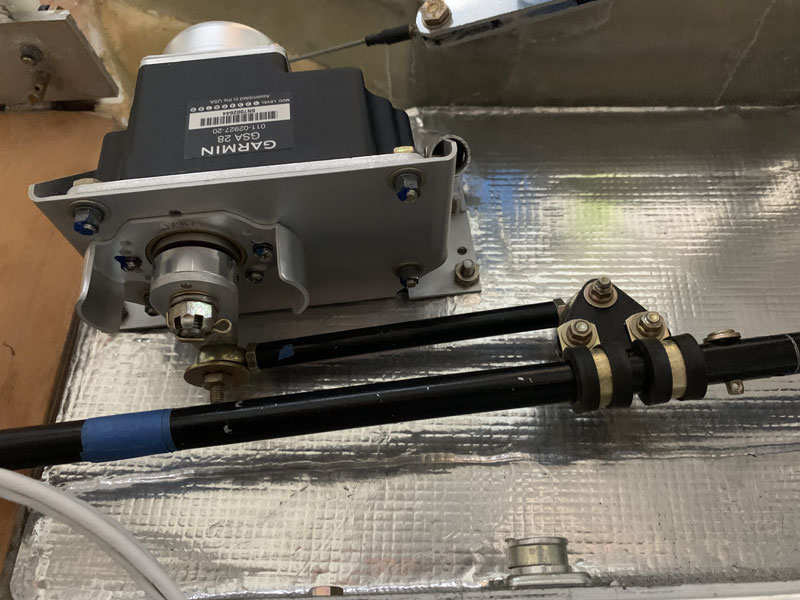

Roll servo again, note the guard I have in case the rudder pedal cable gets too close. I don’t want a sharp edge wearing away the cable over time.

This is the roll TRIM servo and spring. Not yet tightened up but ready to go.