| Date: 05-23-2018 | |

| Number of Hours: 8 | |

| Manual Reference: 21-3 |

Today was prep and execution of the bottom outside skin of the right strake.

Yesterday I made up the two fuel drain hardpoints. 1/8 NPT holes in 1/4″ 2024T3 Aluminium. I alodined these after I cut them out and thats about all I did for the day, on the actual build.

Today was a late morning start into trimming and prepping the strake for its skin.

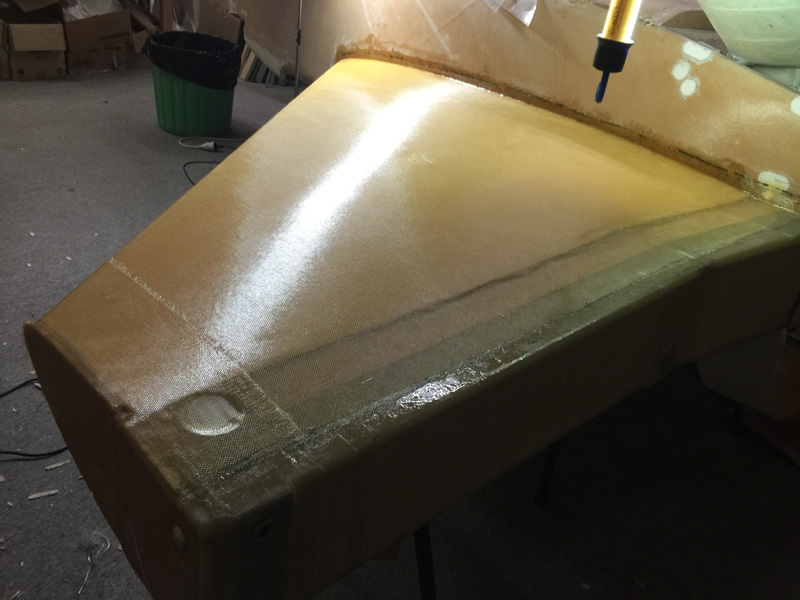

I made an insert down to the glass for this hardpoint and then made it a bit smoother round the edges after this picture.

Finally with the strake sanded and measured and the layup planned. I microed the foam and used a little flox at the edges and for the drain hard point. Next was the first ply of UND and really careful attention to the bias direction. Its very easy for some reason to get this wrong. I really like working with UND, it just seems to behave itself better than BID and if you spend the time you can get it sitting nicely.

Once I was happy I wet the glass out using a roller and trimmed the edges.

The second ply I had all planned to roll out a ply of UND using a cardboard roll as you can see above.

This is one way to get the glass laid out close to where it needs to be. As it happens I had the room quite warm and the cloth was easily moved into position anyway. I think if you don’t have enough heat in the room with EZ-Epoxy its not too friendly.

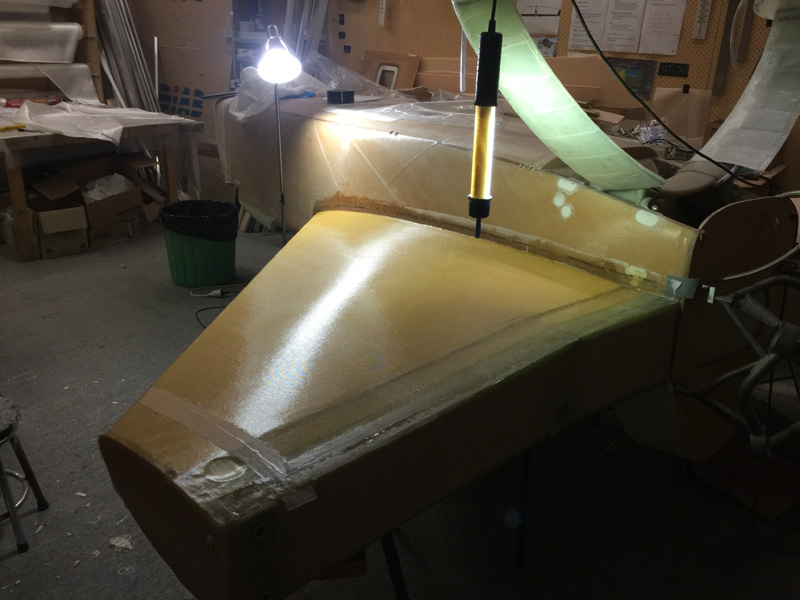

This is with the three plies down and sorted out. That last ply is just 5″ at the outboard end.

My curve towards the leading edge worked out well even though I’ll need a little filler when I put the ‘D’ section on. Structurally it looks good.

From the afternoon start to finishing with the peel ply, its pretty dark outside now and a long day.