| Date: 04-18-2018 | |

| Number of Hours: 12 | |

| Manual Reference: 21-3 |

Over three days I’ve laid out a strake rib grid and got the first two of the four glassed in place. Finding where ‘in place’ is was the first task. I’ll put a little detail here as this was working quite differently to the plans method.

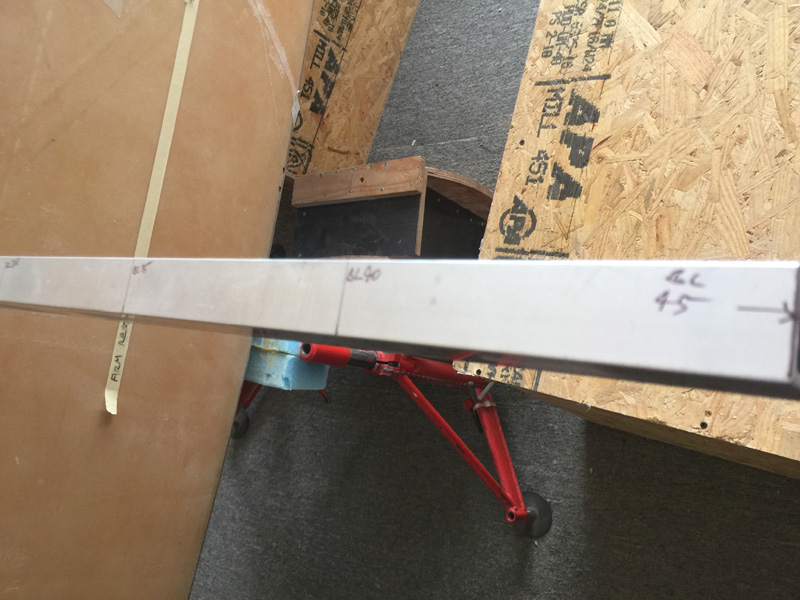

First up I reestablished the center-line with a laser. This was really just a check as I have lines marked already. I wanted a beam forward and aft so that I could get the 4 ribs parallel relative to the aircraft center or B.L.0

Once my beams were in place, just some box aluminium, I marked out the butt lines in 5″ intervals with an extra one at BL23. This and BL45 are where the ribs go.

I spent a bit of time on this and proof that I was at least square was found by putting a builders square in the corners. I was about .1″ out which seems to be my usual tolerance on this build. For once I wandered around and tweaked the positions until I had 100% square all round. I then checked and rechecked various angles and finally called it good. Of course my fuselage was already leveled side to side and front to back.

Note the cross beam in the pic above.

This cross beam is my leading edge point for the strakes. It comes from the fuselage where I’m above the W.L. 17.4 and then blends back to it at the wing.

I just set a block up so my beam sits at the right height and horizontal location. Hot glue yet again did the job.

Here’s the outboard edge. That outer point, on the outside of that wing rib is exactly where the wing sits. I’m having thoughts about the plans fairing block and I rather like a clean angle change here rather than a blend over a few inches. I believe that this sharp change is better in terms of less drag. I will do a little checking with the ‘experts’ before deciding.

I had to angle the rib tips for it all to work.

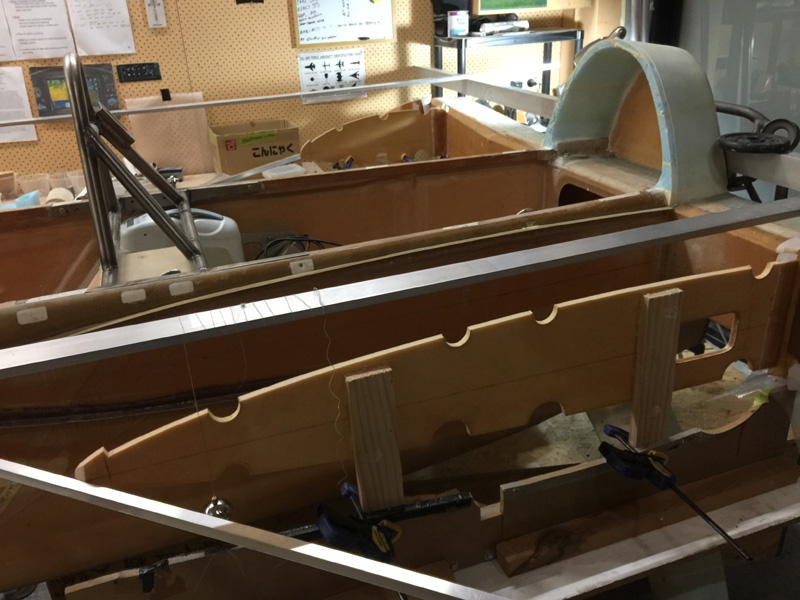

Here’s the left BL23 rib in place. I just used what was at hand. I had the canopy box. On top of that a stool I made which is just handy around the workshop. On top of that were a part of the forms I made when putting the wings onto the spar and finally a bit of timber clamped in place. Whatever works.

I did run around with my hot glue to secure it all. I used the usual two ply of BID tapes at 45 degree bias, the fuel safe epoxy and some peel ply. All these plies are a little bit wetter than I normally do. This is taking a bit of getting used to! I know I’ll need ‘wet plies’ later on.

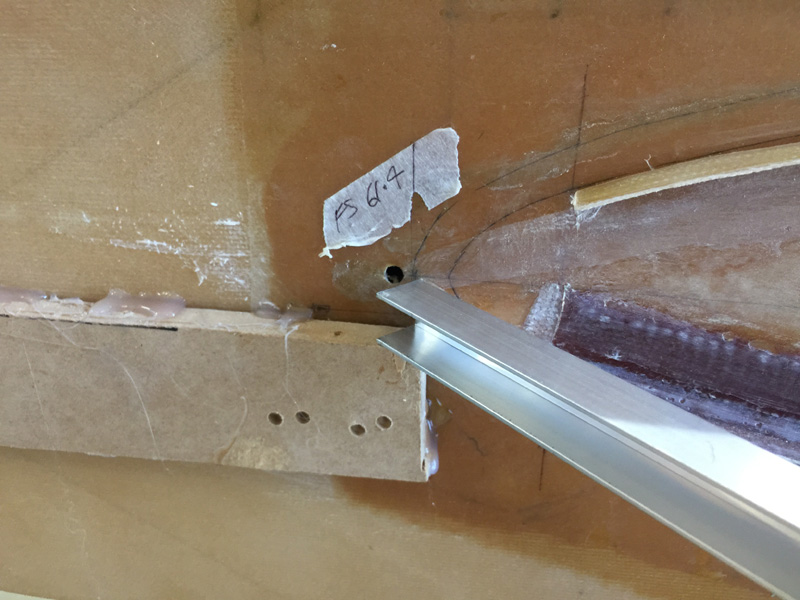

This is a close up of the job showing the plumb bob in use. I had a line on the fuselage for BL23, then I’m using the beam the ensure the datum is carried forward to the front of the plane’s cross beam and of course that I remain right in line with it (plumb bob) all the way to the tip of the strake which is where the cross beam lies.

This might give a better idea of what I’m saying about being in line with the BL23 marked out on the grid of aluminium beams.

Here’s my corner work. I’m going to have to be extremely careful with this join for now. Once the floor is on it will be well supported. Until then I don’t want to ‘delam’ it with a careless bump! I will be putting temporary stringers in to reduce the load here.

With BL23 done I knew that the BL45 on the other side was quite achievable today, even though the sun has long since set. It just so happens there is a workbench under that Butt line. Well nearly… All I had to do was screw a bit of board on to extend that point and I had an instant table.

I grabbed a bit of wood, hot glued a base and added a couple of clamps to have my ‘rib holding system’ good to go.

After I was happy and everything prepped, all the bits got the hot glue treatment except where the epoxy and glass goes of course.

Here are the two ribs set up. Two down, two to go tomorrow. Then we will look at the cross bracing.