| Date: 11-09-2011 | |

| Number of Hours: 50 | |

| Manual Reference: no ref |

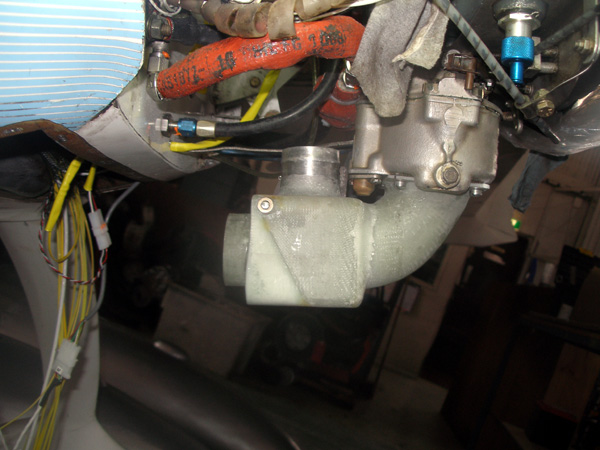

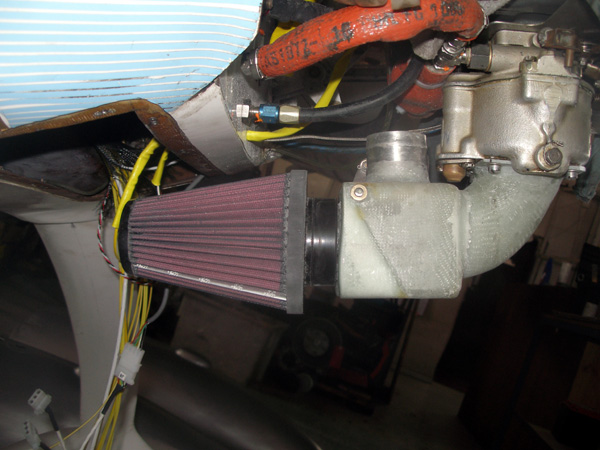

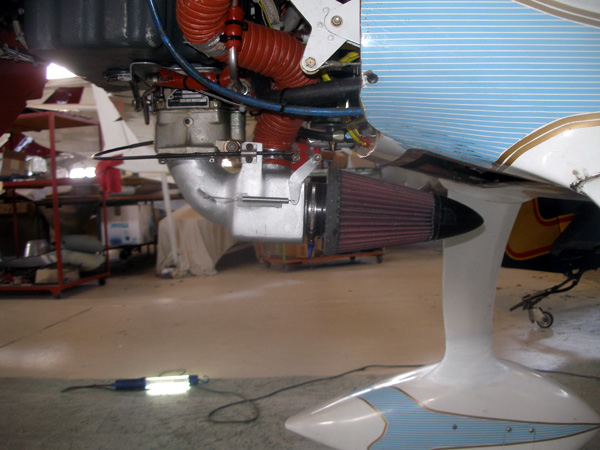

Way back in 2011, my flying aircraft, a Long-EZ, overheated after some engine mods and this needed addressing. I had put in a large air scoop to replace the plans air filter that sits on the firewall. I wanted direct air as this I had read can give an extra 60-80 static revs. Who wouldn’t want that? The problem was that the scoop I choose, which was a sort of ‘off the shelf’ item for an EZ blocked a lot of the cooling air to my cylinders.

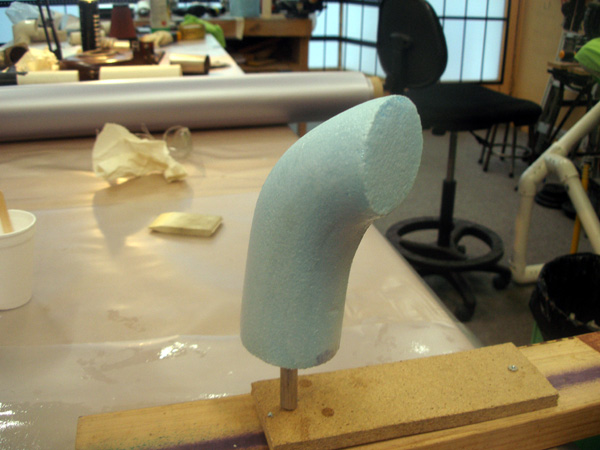

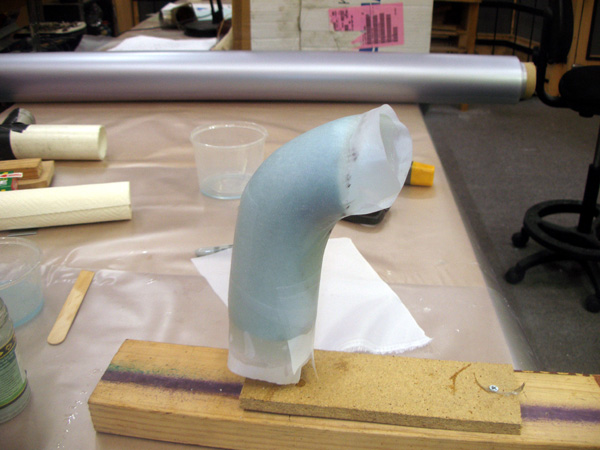

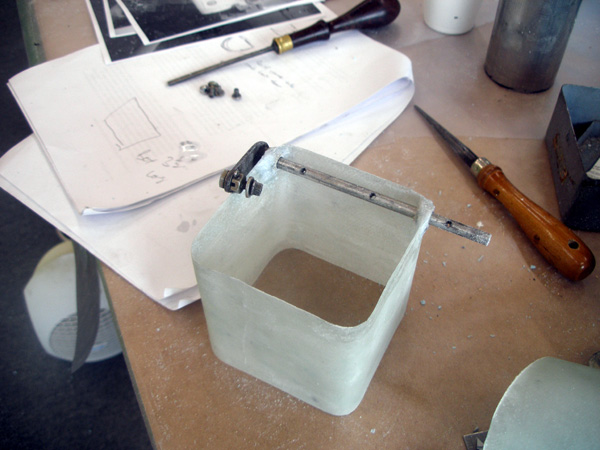

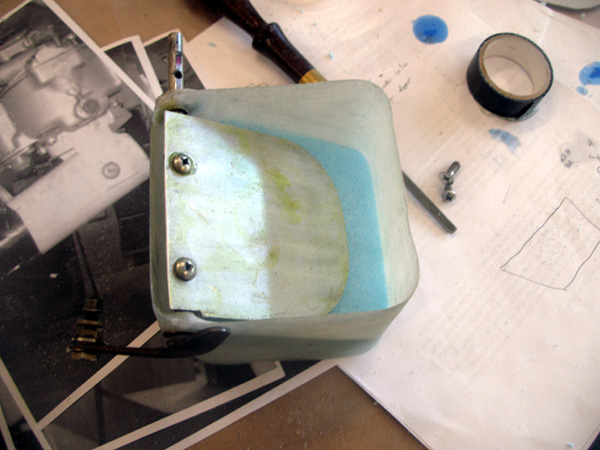

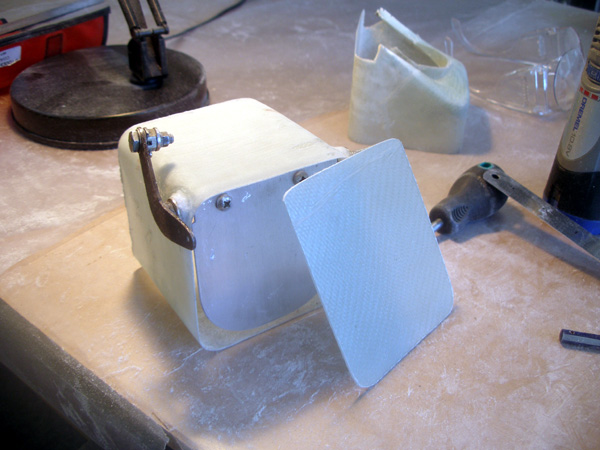

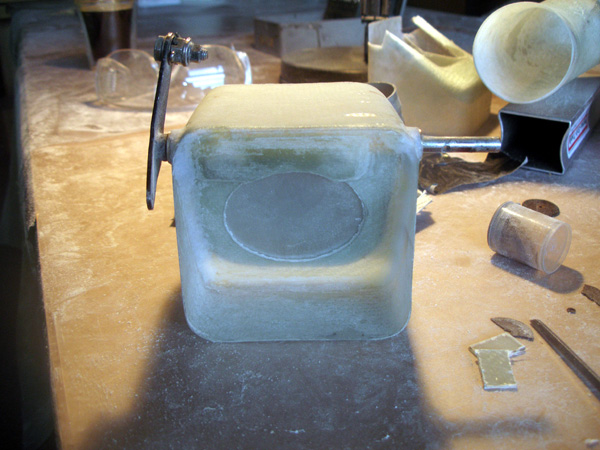

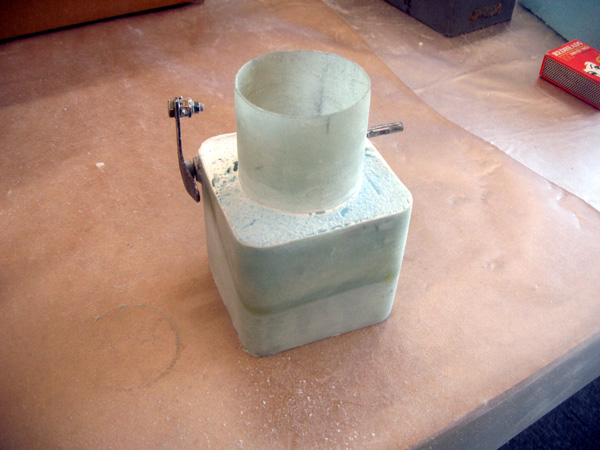

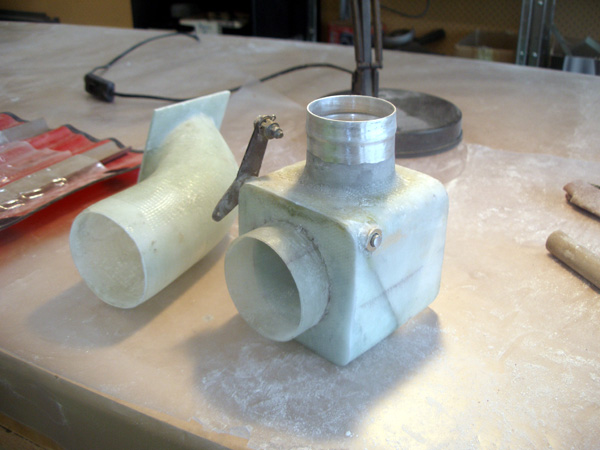

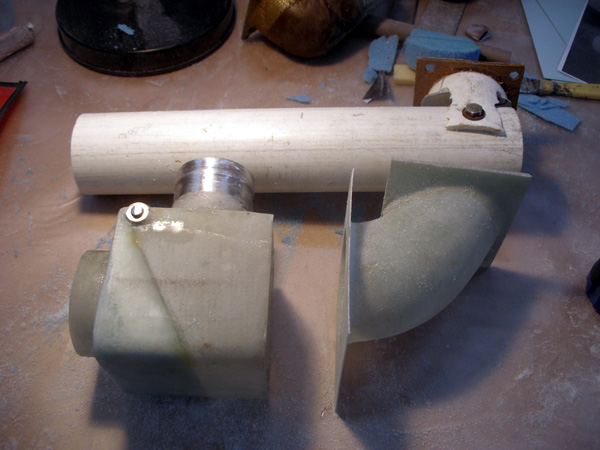

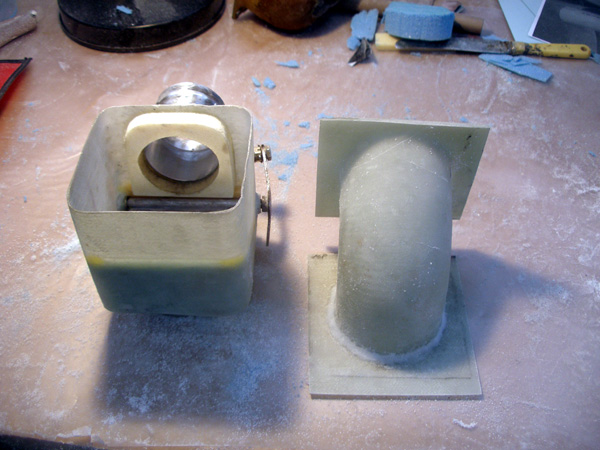

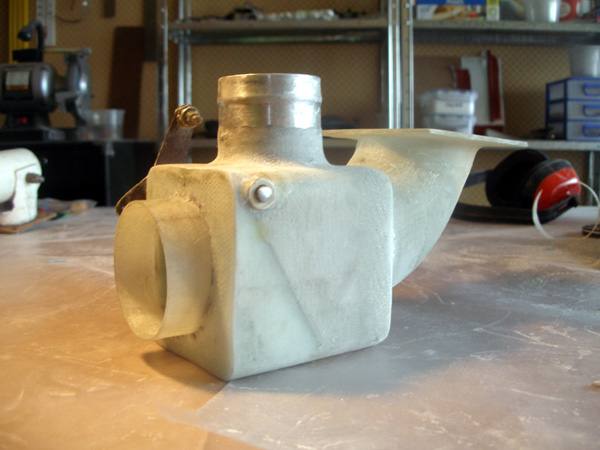

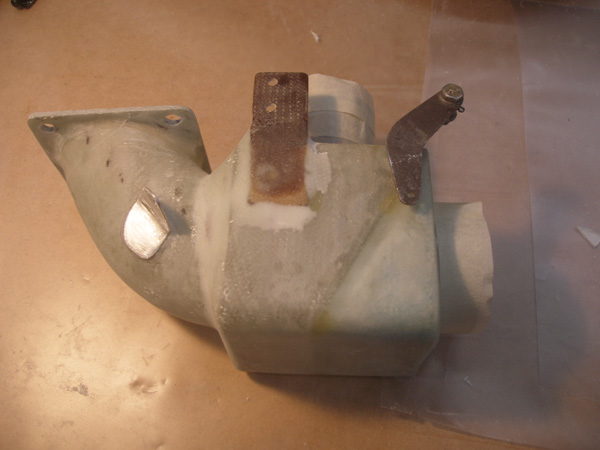

I needed a smaller footprint! So I had a go at making my own box. I wasn’t quite sure how to do it and the design evolved as I made it. I did know that a minimal foot print was the goal and something that I could put an air filter on. I have 79 pictures below to show the process from start to finish.

Almost every step was something new for me. I had done the Chapter 3 education in the Long-EZ plans but that was about the extent of my experience then. Shortly after this I started building the new Long-EZ from scratch, I think the process of this little project helped my confidence to have a go at the crazy big project.

You might ask did this box thing work? Yes, I did achieve a measurable 60rpm static improvement.

After a few years the inserts for the hinge pins were getting oversized or rather oval and loose due to air frame vibrations. I found some bronze inserts in the Aircraft Spruce catalog just the right size, cut the old ones out and floxed in the new. So far so good.

Most of the silver paint has come off. There is a bit of oil and sometimes fuel in that area. If I was doing it again I might use a proven fuel safe epoxy. I think I used MGS in this case and it seems fine so far. I have well over 500 hours on this box now and might do something similar if I had to a second time. Hopefully I could buy something off the shelf, this was a lot of work but very educational at the time.

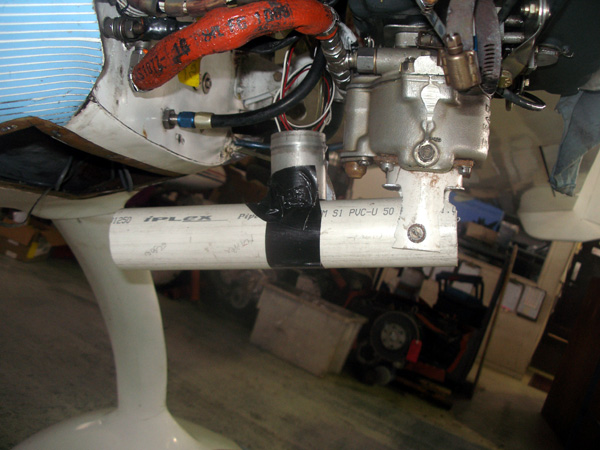

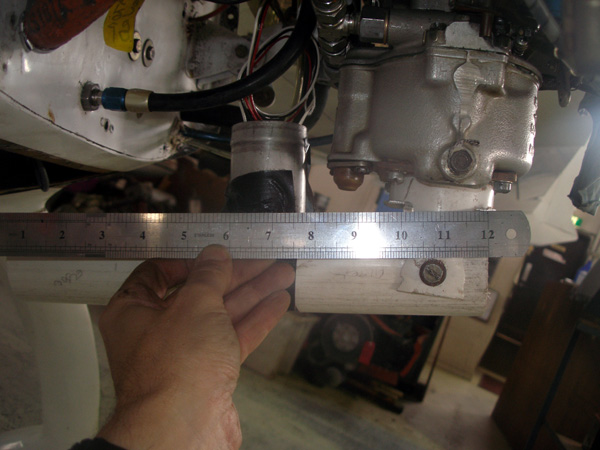

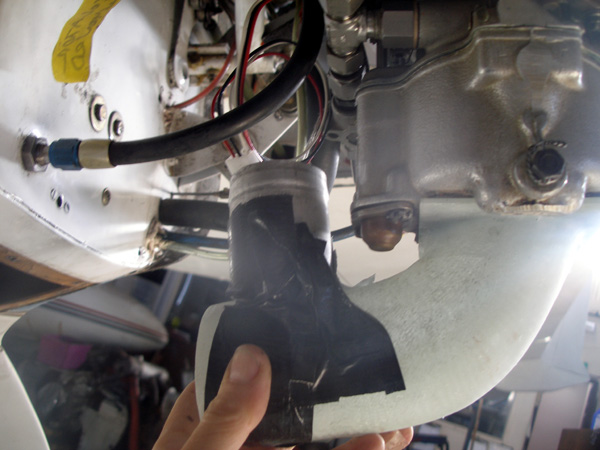

Here’s the first pic which shows that I have made a mock up to get the pipe angle right. The pipe has to point into the middle of the P51 plans style air intake and there needed to be room for the pipes to go on. I used a hinge as you can see that I could tighten and then gaffer tape of course. I don’t think I need to say anymore the pictures that follow tell the story.