| Date: 05-08-2019 | |

| Number of Hours: 12 | |

| Manual Reference: no ref |

This RAM air idea came from James Redmonds excellent build site for his Berkut, a larger version of the Long-EZ. That said I have a slightly different take on it to suit my particular Long-EZ build. This modification I expect to add at least .5 inches of Manifold pressure in all flight situation, for ‘free’. That should be well over 100rpm just by making the engine intake more efficient.

The Mike Melvill designed cowls with armpit scoops leave the bottom of the cowl free for an intake separate from engine cooling. That’s a golden opportunity for an engine opportunist like me.

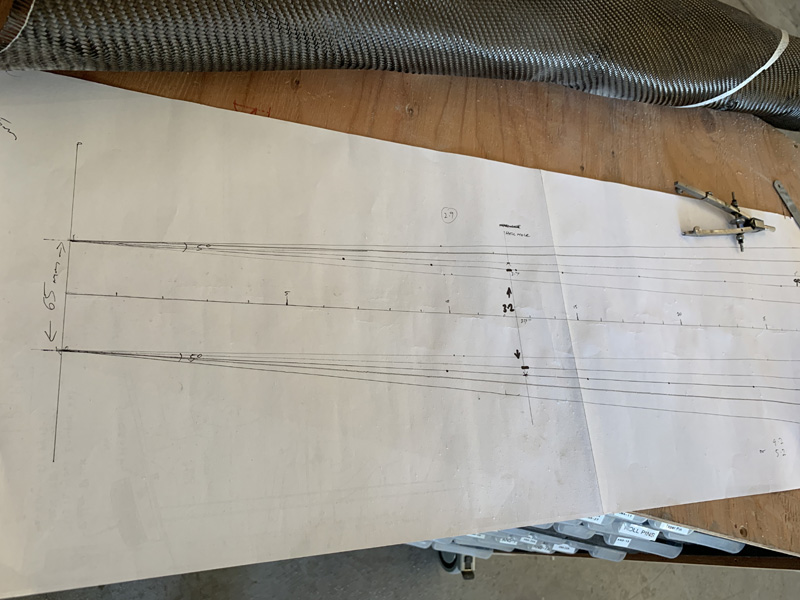

The rules of fluid dynamics tell up that we need to keep scoops less than 11 degrees total side angles or as they say ‘included’ or 7 degrees if only one side of your duct slopes. If you go past that the air goes from laminar to turbulent, no good for our intake into the engine. We want to gather the air, slow it down with expansion and increase the density, like a supercharger on tranquilizers and without moving parts.

I first worked with a protractor and the scoops looked too big. I went back to school triangle trigonometry (via google of course) and the scoop angles started looking correct.

I used some blue foam left over from the wings and marked 65mm being the likely fuel injection air intake diameter. The other end was just as big as I thought I could manage to still fit into the cowl. The duct worked out around 30″ long.

Here’s where it will go and as you see, its not a fit yet.

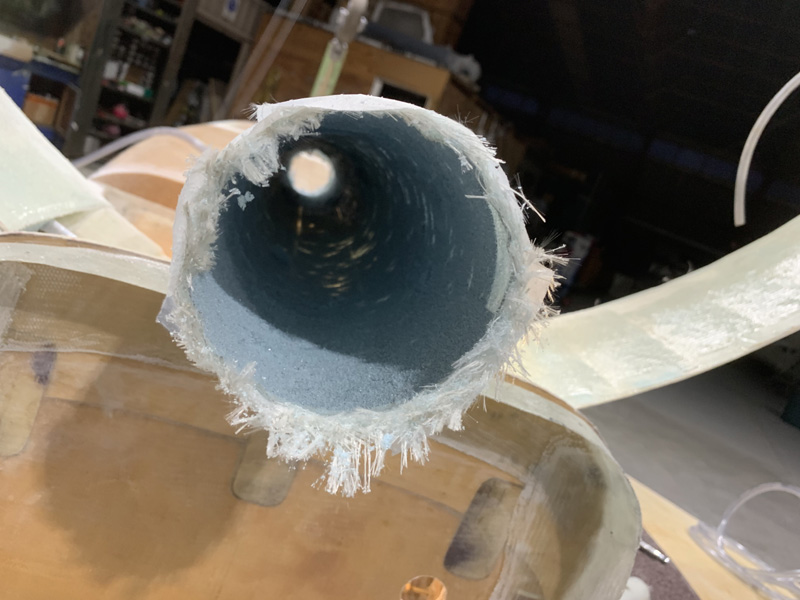

To my surprise I made a really good plug with a long sanding stick and a makeshift jig.

It will be fitting here, eventually.

I covered the plug in grey duct tape and used some jigs from when I made the fuel pipes and an improvised work bench. Fortunately I’d had five guys help me pull the wings off and invert the fuselage a few days earlier.

I used UND for the first ply, then two plies of BID. Yes just that part was four hours. Why am I so slow? Who cares, it ‘got done’.

Peel ply went on at the end which again took a while but will be worth it. Unlike others, I want to retain this duct shape for the air inside and treat the air outside the duct with fillets for blending into the fuselage. This slightly more difficult path I hope might get me better than +.5MP (manifold pressure). I guess I will never know because we will not be doing a no scoop/scoop double blind test. ….Sorry.

Today I scooped out the insides of the scoop. Another day or so to cure and I’ll try to get the grey duct tape release out. Piece of cake.