| Date: 10-20-2023 | |

| Number of Hours: 20 | |

| Manual Reference: 23 |

The replacement sump finally arrived. I’ve removed the old sump and temporarily installed this new one. There was an issue with the entrance to the induction. I spent 6 hours on that alone smoothing out the area that had been attached with a rotary tool. The air needs a smooth introduction to induction after all!

A few more hours sorting out other issues and I have my new sump so the work can begin. It does fit the plane beautifully and gives me much needed space that the other sump was taking up. I can even put the lower cowl on with decent clearances.

The first major task is to size the radiators so I can get them made.

I worked with cardboard to try and find what I thought was the maximum shape possible to see what I had.

The two sides are quite different due to the offset cylinders and various pipes slightly in the way.

I took the cardboard, after many hours of fiddling, down to my radiator guy. He said my shapes were not possible. Woooow… So I returned to the workshop looking for plan B.

As you might see, lots of changes get made to my cardboard shape.

This is getting pretty close. Unfortunately all I can do is a long thin radiator. About 6″ wide by 19″ long, give or take.

The same on the other side, long and thin when I have only a 4″ triangle of incoming air to somehow get to the face of this.

Here you can see the inlet size.

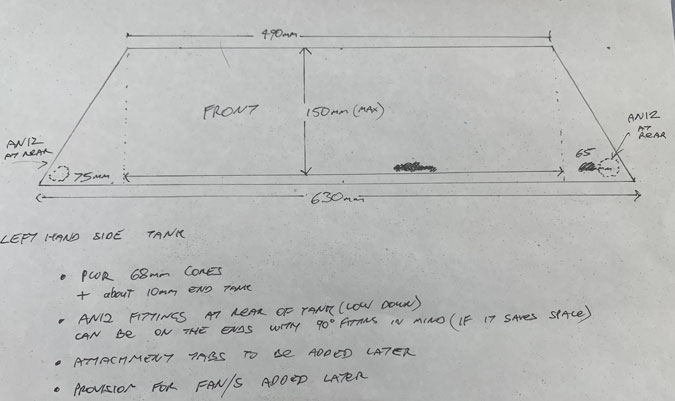

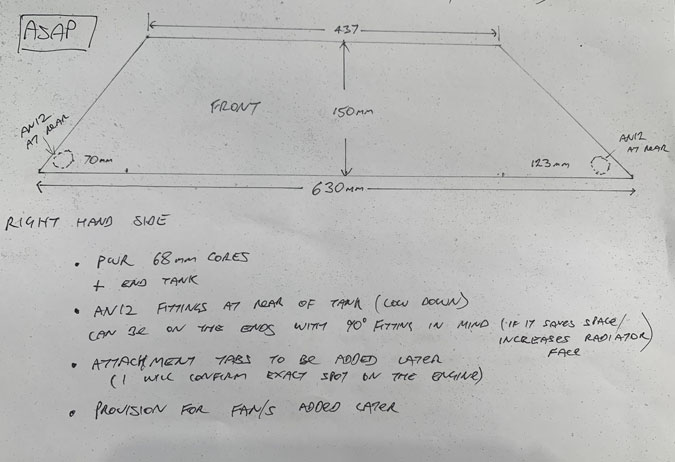

After quite some work and more fiddling I have come up with my two radiator shapes in foam. The right is only slightly smaller than the left. These are 68mm thick which is the size of the PWR high performance radiator cores that I hope my radiator guy can order. I did take them down to him with my measurements, but he was away until next week racing cars interstate. Good for him!

OK, not exactly a computer model in CAD.

In summary. We have the cores at 68mm plus about 10mm more thickness at the ends where the tanks go on. These will be cross flow radiators and include the tank size which needs to be large enough for the AN12 fittings.

They should work out at around 210 square inches of radiator face area.This might be enough IF I could get the air evenly over the full surface. I am going to build an enclosed plenum which should help a tiny bit. I’m also moving pipes and things on the engine to get maybe an extra inch back from the openings. I am really going to have to work on getting the air out which might help a little.

To be honest I am concerned about this cooling, I will be delighted if the first iteration is successful.