| Date: 05-19-2024 | |

| Number of Hours: 18 | |

| Manual Reference: 23 |

If I find myself stuck waiting for a clearance for with the engine running, I have concerns that things may get too hot. Being a pusher I don’t really have good flow through the radiators until the plane is flying. The possible solution is a small fan on each side. When at idle revs I hope this will keep things under control.

The fans rotational speed and when they operate is automated, just like it is in a motor car. I don’t need a manual control, just like we don’t in our cars. The temperature sensor will talk to the fans and the water pumps too and the device will work it all out. All I have to do is set up the controller to some preset temperature.

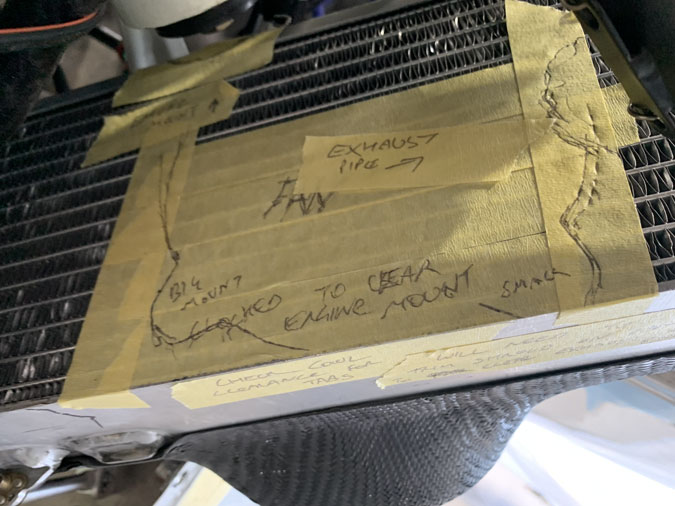

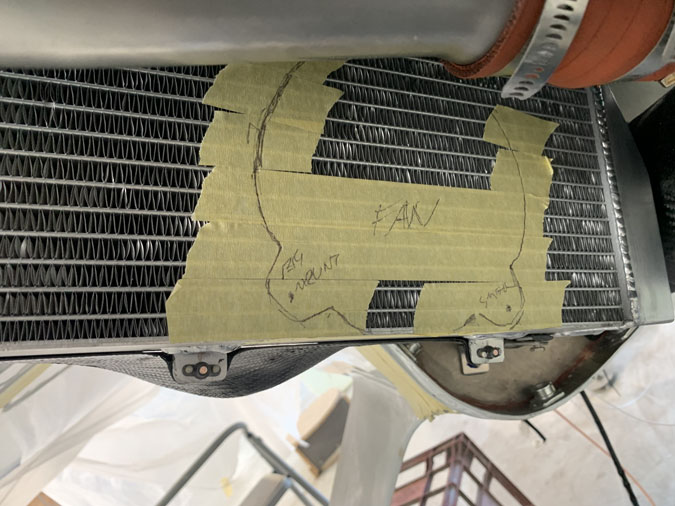

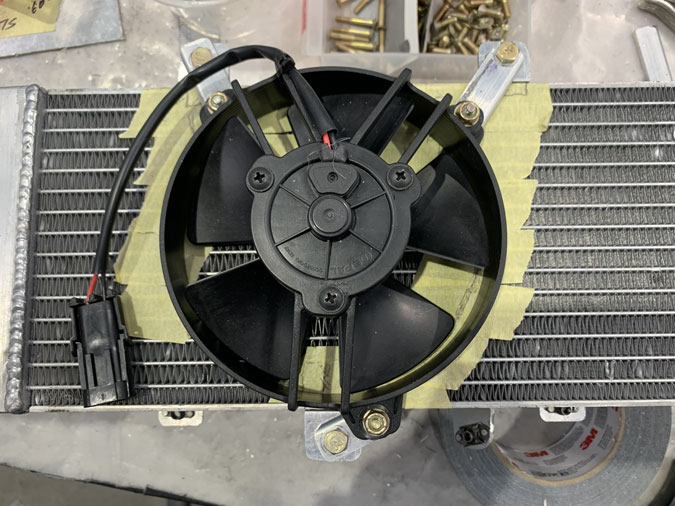

While there is an optimum place for each fan that I had in mind, reality told me the only places they might fit. As it was I had to move an oil line which required replacement.

Each side was marked with the footprint that fits a fan and in what orientation.

Pretty simple really.

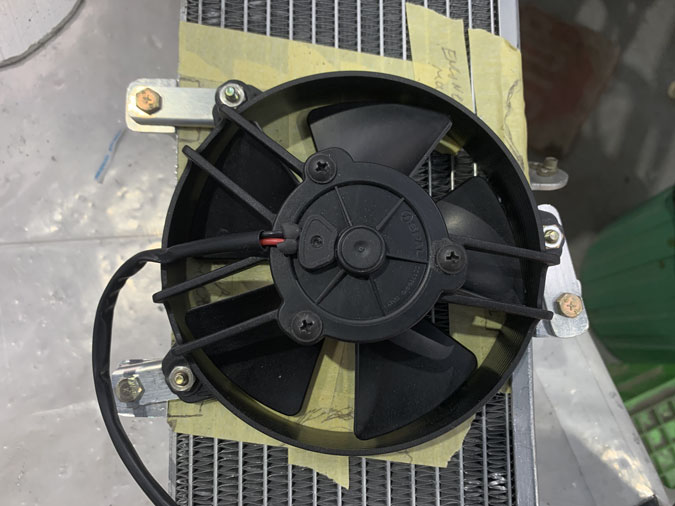

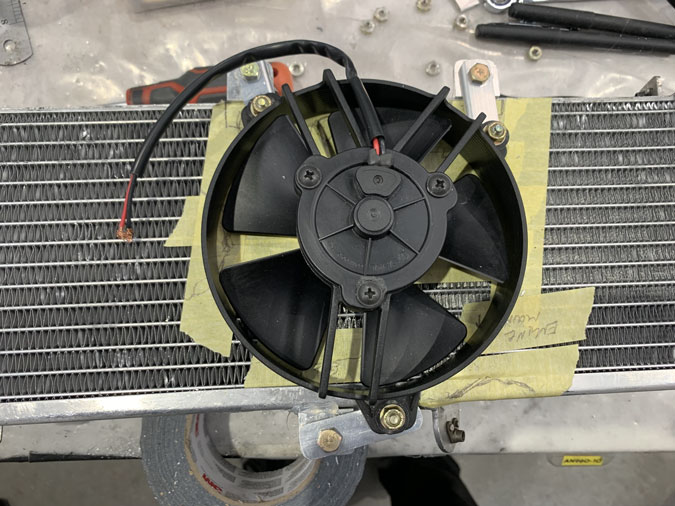

How to mount these things has been on my mind for months. It turned out to be simple, in a way. I have gone for 2024-T3 to make the fittings.

It turned out to be some 90 degree angle and an offset strap.

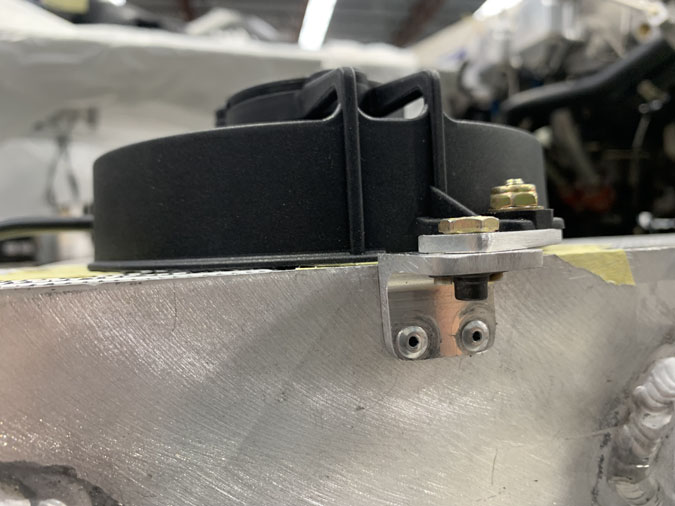

With these offsets I can position the fans exactly and the fasteners don’t bump into each other. Yes I did change the nuts to locking nuts later. This is just for the setup.

I can set the height of the angle pieces exactly and then my plan is to very carefully rivet them in place. After that it can be welded properly. This time things will be exactly where I want them rather than trying to fit in with however the welder ‘places’ it.

It might be clearer in this picture. The next step is to get the pull rivets in place without penetrating the radiator flow areas.

I made a little drill stop but it was still a scary process. One slip and I have a leaking radiator.

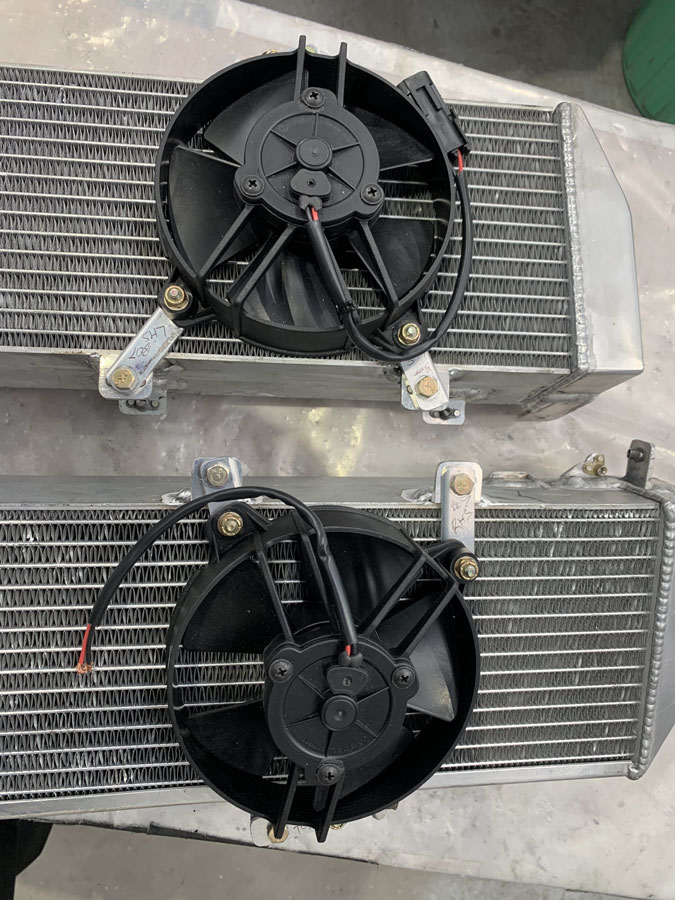

Each fitting now has a couple of pull rivets. These have positioned the fans exactly where they need to be ready for welding.

My slightly strange solution is now in place.

The next step is the welding and then I can remount the radiators. They might need a little trim around the exhaust pipes and perhaps some thermal shielding.

The welding was pretty poor but it will hold. I cleaned things up as best I could. I’ve since trimed one of the fan shrouds so it fits better. I might add some shielding later.

With the fans done I went back to other little jobs. Some nut plates needed moving on the filter box and with that done after an hour or so I installed them back in the plane with the weird idea that they are done until engine start.

You can see some of my lists in the background here. I keep crossing things off and adding more.