| Date: 11-04-2022 | |

| Number of Hours: 12 | |

| Manual Reference: no ref |

A few more little jobs while the wait for the engine continues.

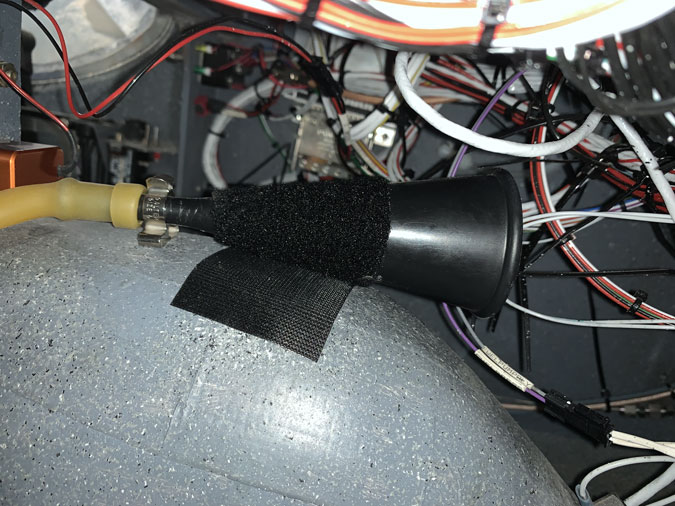

The piss tube is in place now with velcro and some soft surgical line at the end of the PVC tubing.

The soft section of tube takes bends really well and allows the tube to be stored out of the way easily.

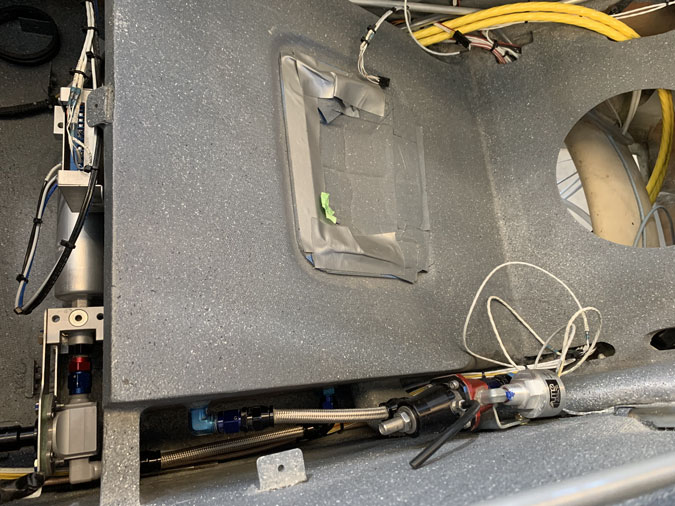

Here’s my canopy breaking tool which I don’t expect to ever need. That’s why I have it. Its well within reach if I ever have to bust out of the canopy after an accident. Its also well out of the way for normal times.

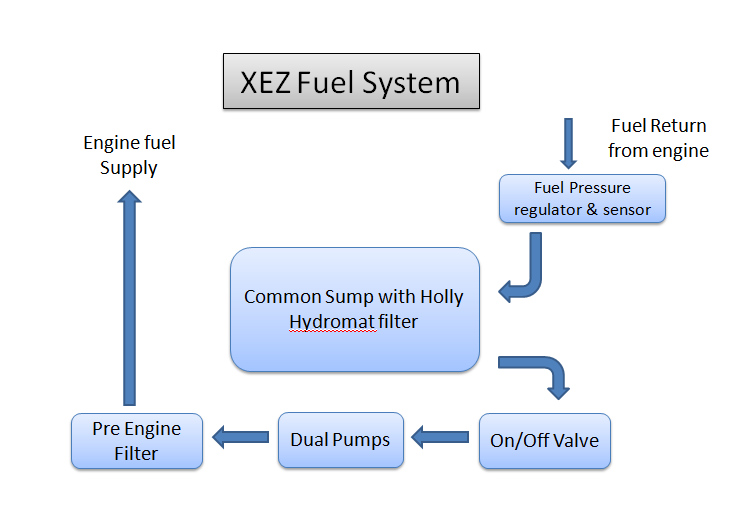

With so little to do while I await the engine I put a few fuel lines back in.

I had to have a think about where things went. Its been a while since I worked all this out.

Its really a very simple system, until you have to make the hoses and get them in place.

A few details not in this simple drawing….The Hydromat filter is 15 microns and the post pump/pre engine filter is 10 microns. I have two vents in each main wing tank and a vent in the common sump all going to a common manifold in the turtleback. They then go down to the bottom of the plane. Each vent at the drain point has a heater in case they become blocked due to icing. They get turned on with pitot heat. We all need a little excitement.

This is what I used for the canopy seals and any other rubber parts that need fixing in place. I just wanted it somewhere in the blog… sorry for the interruption.

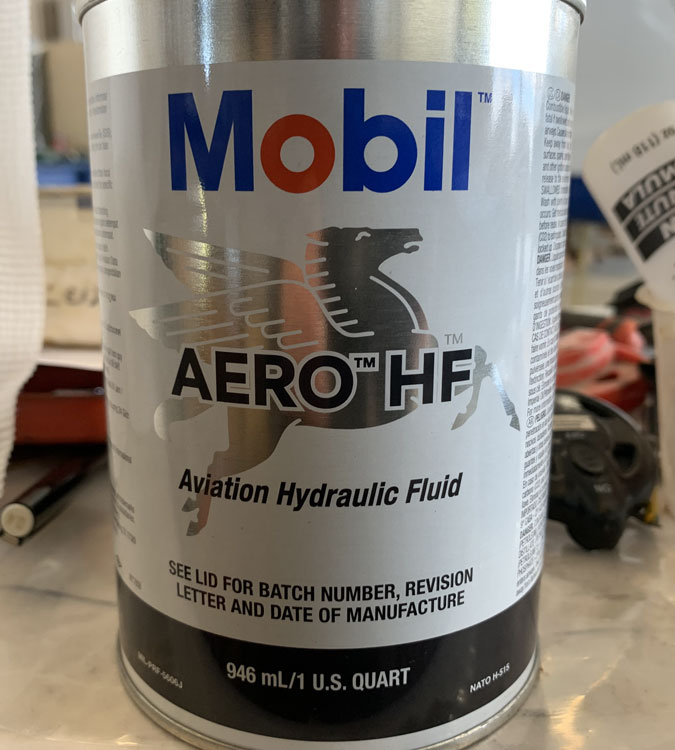

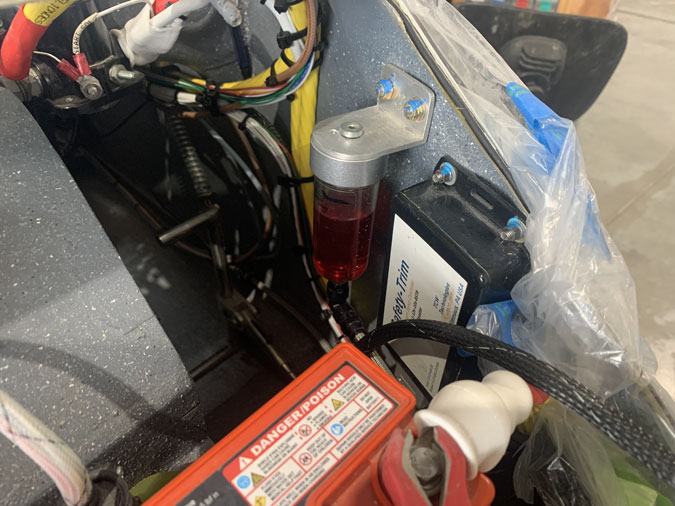

This is the brake fluid I will not put in next week. It is very much standard aviation stuff they use at the airport. Its the old MIL-PRF-5606 BUT I do have something better that I will use instead which is much safer for high temperatures should I have a brake heat issue.

Here’s what AC-43.13-1B says about brake fluids…

Royco 782 which is MIL-PRF-83282

Bottom Line: MIL-H-5606 has been replaced with MIL-PRF-83282 (good to -40F/C) and MIL-PRF-87257 (good to lower temps). Each of these fluids, and their associated systems, are compatible and miscible with each other. You can mix any combination and/or amount of these fluids together without any ill effects.

If, and/or when, you change over from MIL-H-5606 you can either:

1. drain your hydraulic system and refill with MIL-PRF-83282 or MIL-PRF-87257, or

2. merely top off the reservoir with MIL-PRF-83282 or MIL-PRF-87257 as needed.

Both methods have been used with great success with no reported problems.

That said, I would ASSUME mixing the two would reduce the fire protection you get from straight MIL- 83282

This unit lets you pressurize the line. I added a stop valve as I’m filling bottom up and need to check in the nose how I’m doing before I get brake fluid everywhere.

I did get a scare as this is my first time and it seemed like the line was blocked, which would have been an issue. I did blow some compressed air through and got a bit of advice and someone else to watch the bubbles and eventually the fluid come through. It needed about 15psi which required that I hold the fitting in place. Yes I did have a little spill to clean up.

Here we are at the nose. I didn’t fill the reservoirs all the way as when the nose in lowered they might spill out the top breather holes. I will be watching the first time I lower the nose all the way to the ground. That will be the MAX line which I will mark. For now, I have brakes!