| Date: 06-21-2020 | |

| Number of Hours: 36 | |

| Manual Reference: 22 |

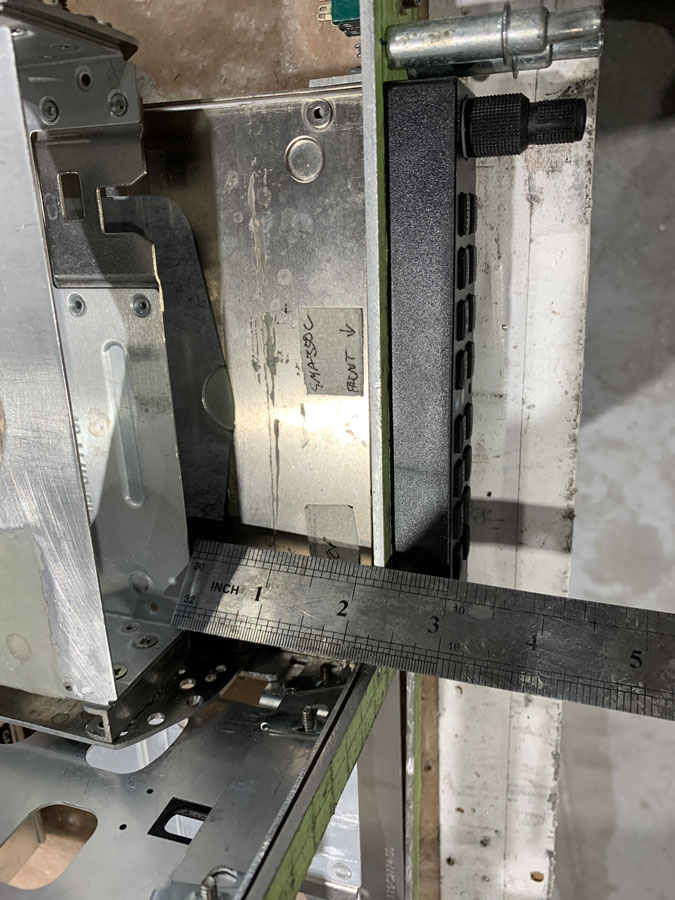

Having done a trial fit of the instruments I found that I had missed a clearance by about .2″. This meant that the main screen would not go in. A minor problem? Lets call it for what it is, an opportunity to do better with a massive refit.

I allowed a good gap for the back of the main screen. BUT… I should have measured with the ADS-b box in place because it protrudes about half an inch from the edge where the ruler starts. This meant that that tray AND everything above it has to be re-positioned.

The audio mixer was still in the right place so I just needed to work around that.

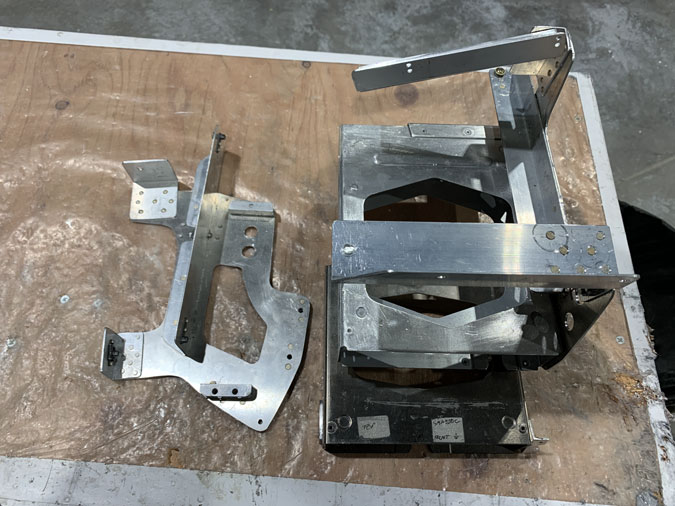

I spent some hours working with my existing panel bits and moving pretty much everything back .5″ so I had that needed front clearance. Despite all the work I knew I was going to have to replace the main side bits where all those nutplates are. I wanted a correct starting point for the new parts so modified the old ones first.

Using the old parts as a template I fabricated these two 2024 T3 side pieces and added the nut plates. There is also a new fixing system for the third tray item, the remote VHF radio. I have tried to get everything in shear rather than tension for the fixing. I’ve also reduced the final weight by using some open box fillers rather than solid aluminium.

I have learned with this third version lots of little clearance issues. Rather than a redo, its building on knowledge to try and get a cleaner, lighter result for this tray. In most aircraft, installers have a little more space for so many instruments. Of course it wouldn’t be my EZ if it was easy.

This was the clearance issue and as you can see now there is plenty of room for that top Garmin item on the left as well as the one underneath that was the problem. You can also see the main screen back at the right has plenty of clearance for air circulation, something I always have in mind for this tight install.

Getting that top VPX fitting (the red box) has also been changed. I’ve streamlined the mounting system to make removal easier. I have a slight slop on the top. If I get water going in, it will be to a known place rather than everywhere. Of course I am NOT going to have my hatches leak. At least thats the plan.

Here’s a close look at the internal fixings. Lots of rivets and angle aluminium.

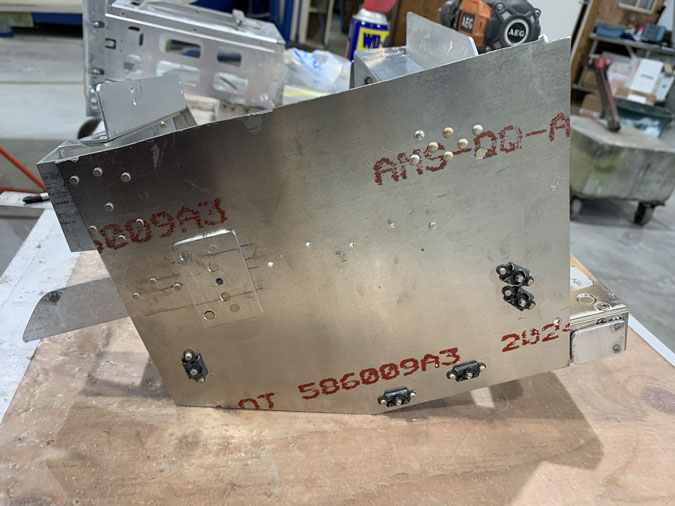

Yes those side pieces are massive aluminium plate! Now that everything fits in that center section it just needs a bit of a ‘trim’.

This side all fitted and in place became…

This piece now with metal removed to make it lighter and stronger. Maybe its a modern art sculpture too. You decide.

Here’s the side ‘before view’

Here’s the ‘after view’ of the side piece.

The ‘finished for now’ center tray mount.

Here it is with the left trays that will probably be my next item for a rework.

A close up of the middle bit because after so much work I want to see it again.