| Date: 01-24-2020 | |

| Number of Hours: 20 | |

| Manual Reference: 22 |

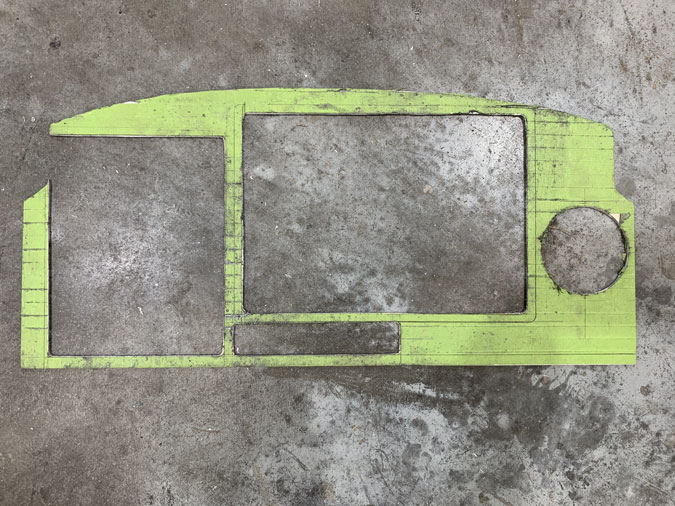

Moving on with the Instrument Panel. My first version was in MDF, time for metal.

I’ve gone for 5000 series .125″ aluminium for my first proper metal attempt. Cheap as chips. It really is a bit too bendy so I may go for 2024T3 as the final. I’m pretty sure I won’t get this done in one attempt. With the final panel thickness I can set things up as if its the last version.

After fitting the panel to the plane I went with my MDF template to do the cutout.

I just covered it all in green tape to ‘practice’ protecting the metal surface. It’s also great for drawing on. Just a jig saw and files. That’s metal files. No CAD files for me at this stage.

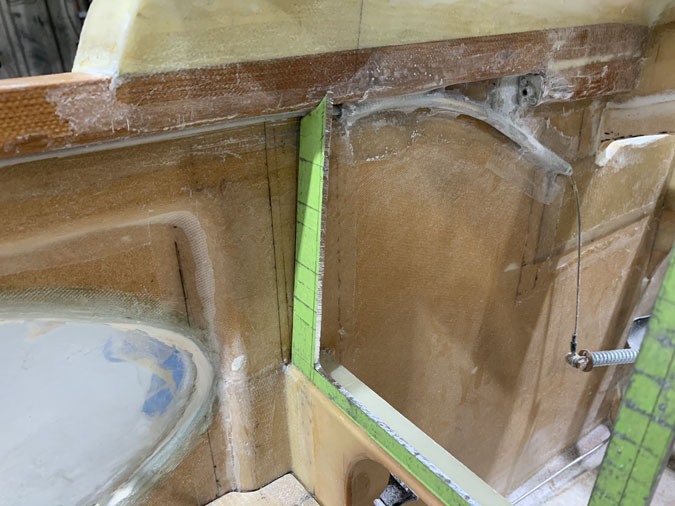

It fits, more or less.

Here’s the angle idea left side.

…and right side. Its down to around .8″ at the top compared to parallel to the bottom of the panel.

Apart from looking cool, I needed the panel sitting down at the rear so that the tray of the GTN750 fits. You might see how it would contact at the rear if the back end was higher i.e. straight instead of slanted at the front.

Now you can decide if the slanted back panel idea was a design decision first and a fit realization/necessity after, or the other way around. I’m not telling.

Just a note if anyone is reading this.

I am now doing my instrument rating which is around 4 days per week. The rest of the time I am studying a few things and mainly doing approaches on my home flight sim. This is going to slow the build over the next two months almost to a standstill. Given no word on an engine delivery date it is probably good to get the flight instruction I need now. Even better if I pass the eventual flight test, be it sooner or later.