| Date: 06-30-2020 | |

| Number of Hours: 38 | |

| Manual Reference: 22 |

Time again to remake the panel face. The first time was in MDF. Then I went for 5 series aluminium as its cheap, a little soft and I expected to have to do another one. To my surprise it turned out pretty well but it did need a couple of minor changes which was incentive enough for a third panel face.

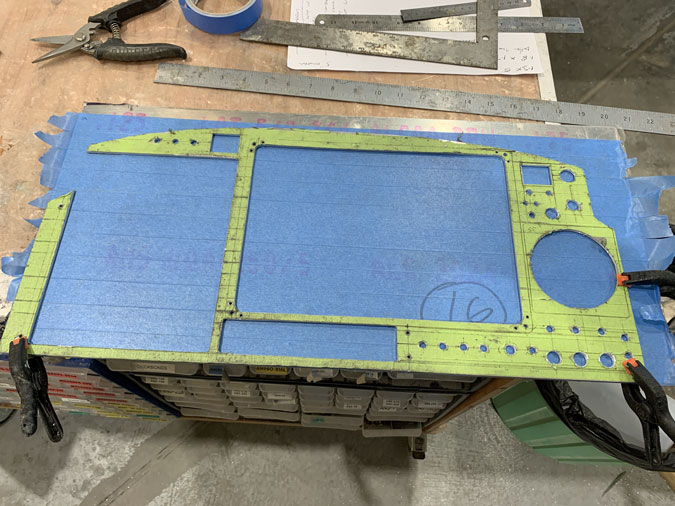

Here’s a test fit with this second 5025 sheet. I added a switch next to the dimmer which is too close and a couple of other switches just needed a small change. Note that the audio panel and the main G3X screen are not inline by a .1″. That was a deal breaker for trying to save this panel and forced me to go again doing another front face.

I’ve gone to 2024 T3, proper structural aluminum. Perhaps overkill as I’m cutting so much away that the weight and strength is not significant. For now its pretty heavy in an uncut sheet.

I’ve again just covered the new face metal in blue tape and I’ll use #2 face plate attempt as a template for #3.

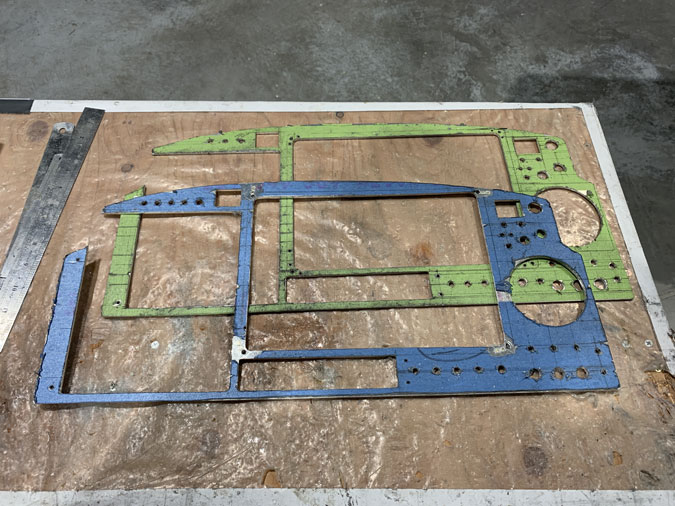

As before some work in getting it cut to fit snugly.

After another day the main instrument cutouts were done.

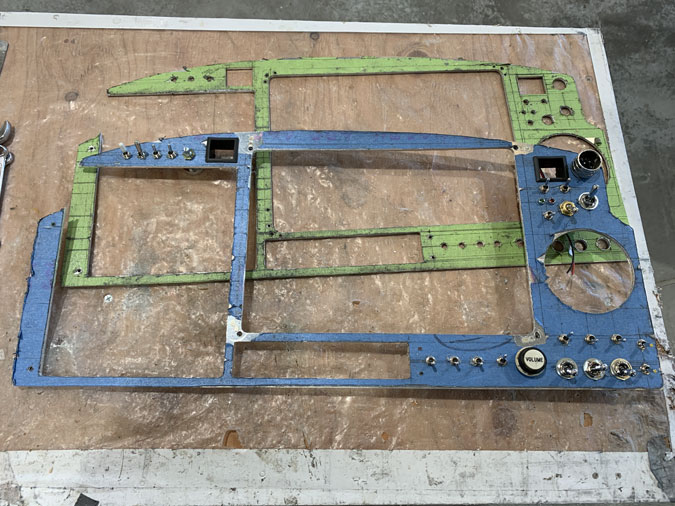

Test fitting worked out although the GTN750 is just not fitting in easily and takes a lot of jiggling. Its not OK yet.

I went ahead and re-drilled the switch holes. The ones on the upper left are a bit too low by maybe .1″ I may get away with it. I’m overall happier with the small changes elsewhere. It doesn’t weigh much now!

The other thing you can hardly see is that I have mounted four nutplates to hold the main screen. This turned out to be a ton of work as there is very little room to do anything and the alignment was critical. There was no room for floating nutplates. Its passable but not perfect.

Here we are populated with dummy switches and a knob. Yes nine days work is covered in this blog entry. Still lots of fitting to do but this is progress.