| Date: 09-13-2019 | |

| Number of Hours: 12 | |

| Manual Reference: 25 - Paint testing |

I have been very interested in rolling on paint rather than spraying for some time. After a lot of research I purchased some roll on paint. Soon after I found a better candidate to begin the testing on and bought that too.

My self brief was:-

- I wanted a paint system that I could repair or touch up with a seamless result.

- Do it in a busy hangar with other planes nearby and people working and where the doors are mostly open.

- Have the process under my control rather than needing spray gear and a booth.

I set up these panels and prepared them to a smooth finish. Then on went the primer undercoat. I will add I had spent many hours watching you tube videos and seeing guys get amazing results. I was hoping for the same.

Well I never got even close to the you tube experts. They were using different paints but I think I have something similar in ALTEX ELITE 321 boat paint, made for rolling on and tipping. Tipping is just lightly dragging a quality brush through the wet paint to break up any little bubbles and try to get the surface very even. Then this special paint is meant to self flatten and the brush marks mostly disappear.

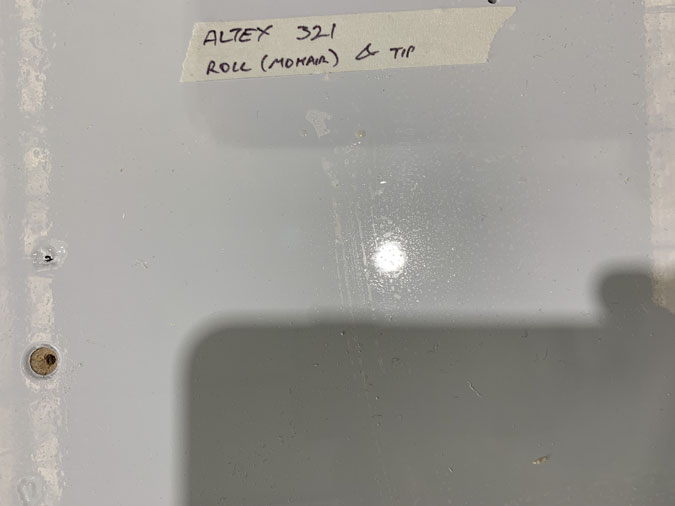

Here’s my best result above with Roll and tip only. It is about the standard of a poor spray job. Pretty much what most of our local GA fleet looks like apart from some very fine bush marks. Thinner paint and more coats would fix that. The surface is slightly rough to the touch. A three foot paint job if your eyes are not perfect 😉

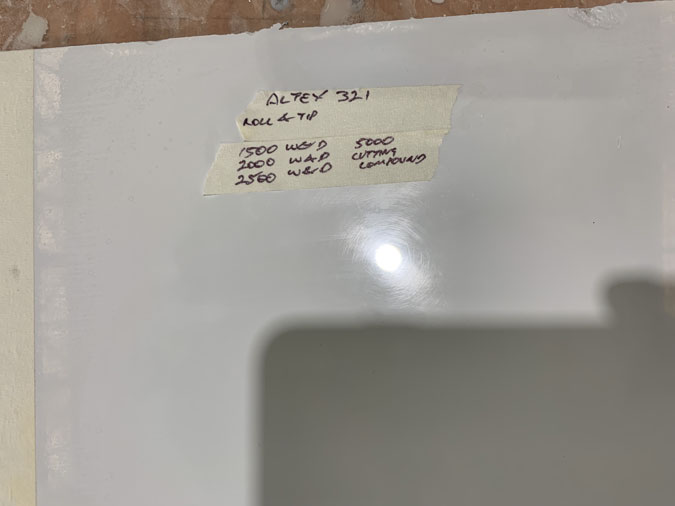

After this I went and saw some car refinish suppliers who are experts. Given I wanted something a little better than a rotten spray job, it seems I have to sand and polish after the paint application to get a good result. The pic above is what I ended up with after the sand and polish process.

Bottom line….

1500 Wet &Dry sandpaper gets all the bush marks and bits of dust out very quickly for a flat finish. I’m using a spray bottle with water every few seconds to prevent scratches from small particles. Then 2000 W&D and then 2500 W&D.

The last step I used is polishing with 5000 compound using an electric buff with a foam pad.

The finish is very good. It is really super smooth, like glass! This has to be good for all the bugs to slide off when I get this thing flying.

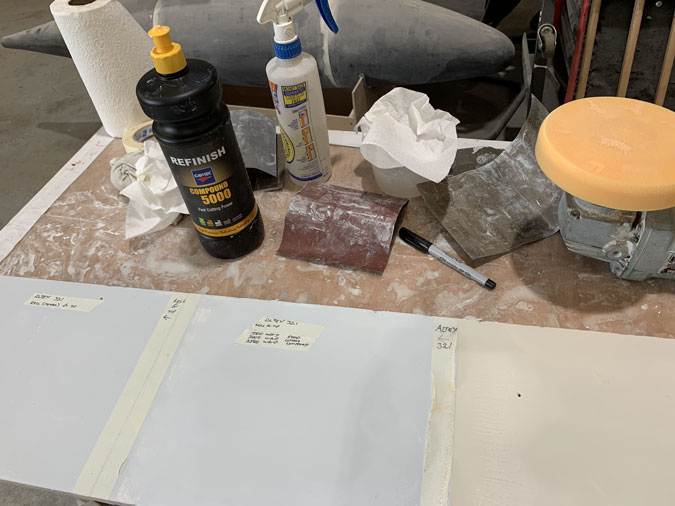

I did about 20 test panels trying different materials and grades of paper, different paint thicknesses, more or less thinners etc. I was really surprised that I could go from the brushed finish straight to 1500 W&D and that the quality of my brushwork really didn’t matter.

The cream panel on the right (above pic) was just a thick coat (of PPG paint) and no tipping. It needed more sanding to get it flat but otherwise it was just as good as the more careful work. ‘Careful’ would equal less coats, a more even paint thickness to sand and less weight perhaps.

Altex recommend 240-320 grit paper final sand before primer. The prep would be otherwise no different with any coating to whatever standard you want to achieve with guide coats and filling IMHO.

The paint again is Altex Elite 321 brushing polyurethane Galleon Grey is my chosen colour. They only have 6 different colours to choose from so I was lucky this one is suitable. The Altex manufacturers claim great UV protection and its made for the outdoor boat environment

I suspect any paint would end up with this surface given the sanding and polishing process. I also tried some PPG paint which was very good. Perhaps even better in the finish but I didn’t like the way it rolled on and it might have ended up heavier.

In conclusion, I have my paint after years of thinking about what to use, lets move on.

2 Comments. Leave new

How about repairs and blending the paint after a repair? Did you test methods for this?

I redid many of the test panels and once you have it sanded flat it all seems to blend seamlessly after you have re-polished.

Being able to ‘repair’ was a part of the brief. I didn’t do specific tests for that however, good catch. I was satisfied (via retesting on the same surface) that the process did give the desired ‘invisible mend’. 🙂