| Date: 05-11-2024 | |

| Number of Hours: 15 | |

| Manual Reference: 23 |

While I already have an expansion tank, I also want an overflow bottle. The expansion tank is a little small at around 1liter and I think I want a greater margin, the extra is another .8Lts or so I think. With a small bottle I can more easily top up as required, visually inspect without removing the cowl and prevent fluids going overboard if I get too hot.

The main aluminium expansion tank is pressurised and has the radiator cap. If the pressure gets above 1.2bar, or about 17psi, the cap pops slightly allowing fluid into the overflow bottle. As the engine cools down the fluid is drawn back into the system and the valve at the cap closes again.

This is the third bottle I have purchased. <sigh> I just couldn’t get the other ones to fit and this at least is a proper Rotax bottle so I know the plastic is OK for under the cowls. The other ones I bought were automotive so just as good really. Let me know if you need a weirdly shaped vessel.

Somehow it needs to fit here. Kind of suspended in mid air, exactly positioned so it is very close to the oil filler but not touching. It also needs to be accessible from the oil filler door, not too high or too low and not interfering with adding oil either. Oh, and easy to fill via that door too.

This is the idea.

OK, its not that pretty. Be nice, it took a day of head scratching and thinking to design.

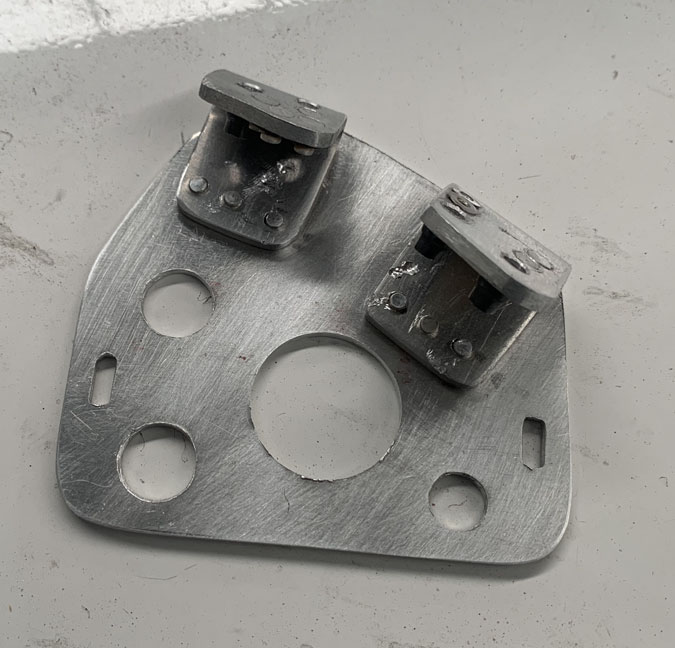

Here’s the idea. I’ll support one corner with a hose clamp on the engine mount. This smaller bracket will take up a little of the weight of the bottle and fluid and stop it wiggling around. The main support needs to be from the top.

I started with some mock ups, again after thinking of a lot of options. Staring and thinking is my modus operendi followed by more of the same until something to try feels right. The plan is to suspend a plate from the underside of the cowl lip and cable tie the bottle to that. Because the lip is curved I’ve needed to go for two brackets on weird angles with exact bends in the supports facing onto the flat plate.

Here’s the idea in practice.

Now you can see if I strap the bottle to the plate and have it also supported in the lower right corner, it should work and be where I want it.

I had to make a lot of brackets to finally end up with these two. I thought I was doing the right thing using really strong 2024-T3 aluminium and bending them, but I kept getting cracks. After three sets failed I took a break and did some reading.

2024 is not really recommended for bending. Three series or five series is the go. 3030 seems best but I found some 5083 and I was very careful to get a nice wide radius bend using the big brake in the hangar.

Then I went and made them small to save weight. Doh! I should have sized for the nutplates first and I made an easy job very difficult. I’m learning something every day as well as making brand new mistakes. I still got it done.

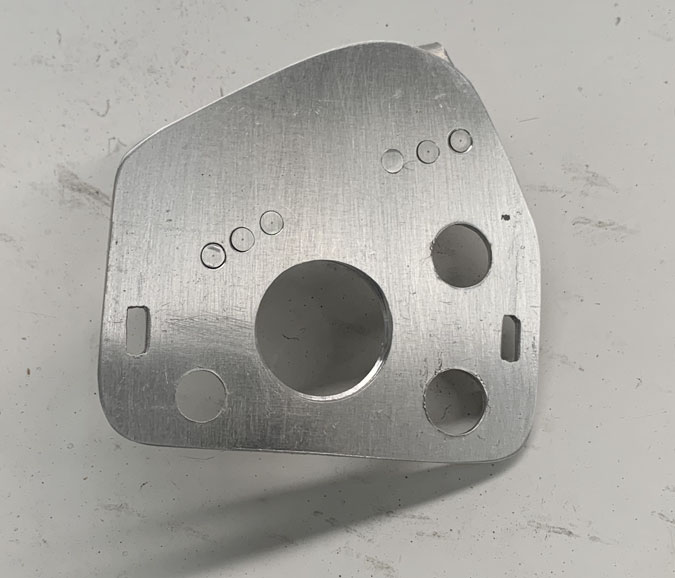

After a bit of a clean up its not too bad. I added the holes to reduce the weight a little. The slots are for the cable ties.

It is not so pretty around those rivets. I had an ‘interesting’ job getting it done. Next time, rivets first, trimming to size later.

I had to pull the radiator out to secure the lower bracket. It seemed a good time to add some fireproofing to the cowl pocket. I was leaving this in case I needed to introduce some extra cooling air but I have changed my mind and is can be removed later if necessary. I still have to do the other side next time that radiator is out.

Here’s how the bottle is supported from the bottom with that backup bracket.

From the top the bottle is very secure.

You can see ‘we’ have met the brief with both fluid items accessible via the oil door. I still have to install the hinge and fastener for that too!

This shows how tight things are in that corner.

Finally a bit of an overview. I just have to add a bit of hose and this part of the water circuit is done.