| Date: 05-29-2024 | |

| Number of Hours: 10 | |

| Manual Reference: 23 |

Since building this door it has been pointed out to me by a particularly knowledgeable expert that there are issues down the track for CF and aluminium. I’ll omit the names. Here’s what he said when I asked for what I should do in this situation i.e. I need the strength of rivets in my carbon fiber structure to join parts with a hinge.

“…when I built the CF ailerons for (name deleted), I layed a barrier ply of very fine fiberglass cloth over the aluminum inserts for the hinges, and then used monel “pop” rivets to install the hinge halves to the ailerons. I determined this to be the best combination given the galvanic series in play. One can install squeeze rivets wet with a sealant (e.g. Proseal) and wipe off the squeezeout, in order to better-isolate the aluminum from the CF, but this is still a crapshoot, as end-on CF fibers can still impinge into the shanks of the rivets.”

I didn’t know what a monel rivet was so here’s a google result

“Monel” refers to a group of nickel alloys that provide enhanced capabilities to withstand conditions that other materials cannot. Monel rivets are commonly found in aerospace, marine, and oil and gas production/refinery applications, as well as in high end musical instruments, among other uses.”

Ok, back to how I did this without the above variation.

I got the rivets in the hinge OK. The door didn’t quite close as well as before. I just bent the curved section of the hinge and it settled down again. Despite being really careful, this is a moving platform.

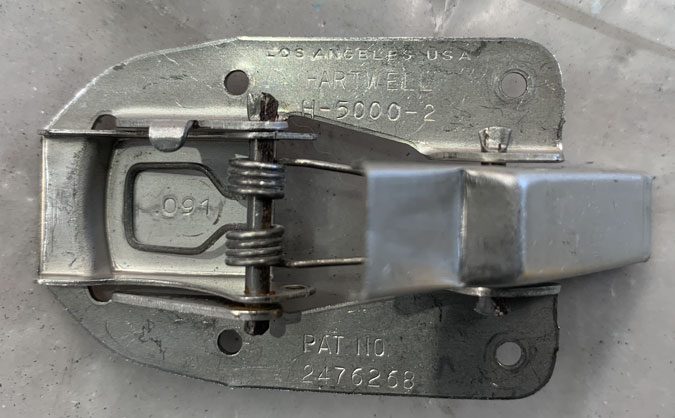

Hartwell H-5000-2 The 0.91 might refer to the height of the tongue in relation to maybe some other bit of this fancy mouse trap aka finger trap. It’s a standard GA part apparently.

I was going to use a smaller push button hinge that was tidier and required much less force. I just wasn’t happy with the striker plate arrangement on that one as it seemed quite marginal to me. The slightest shift and the door might pop open, or need resetting. So this monster is going in.

I stumbled around trying to envisage how far from the lip this should sit. In the middle and back a bit seemed like it would work for putting in the striker.

It is always a bit scary to cut into a nice structure. Yes I’m working at nights as well as days now. 7 days a week trying to get this thing done.

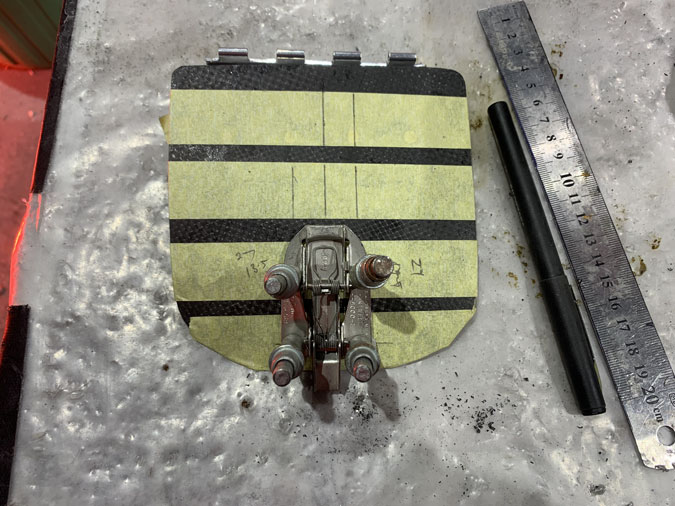

I found I had to get the hinge lower to match the striker position. I was also dealing with a curved surface and if I just clicoed the hinge in place the door distorted enough to ruin my nice fit. Here I’ve gone with four plies of CF, then trimmed the edges after cure. Next I laid a bed of micro to get a really perfect fit for the latch. I guess I got a bonus of isolating the steel from the carbon to some degree.

I used tiny screws and nuts for this micro cure as I didn’t want to distort the door. It still did a little but at least I put in the effort. <grin>

To my surprise the door with the spring in the hinge is so powerful that it straightened everything out and it sits really well. Who knew? Next up was a striker plate. I’m using chrome moly for its strength and I did prime it well as that stuff rusts as you look at it.

I also needed to embed the striker to match the tongue. Too far and the carbon thickness would have been compromised there. If I’d made the hinge any deeper if would have looked pretty bad. So it was a juggle between the two. Of course if the hinge was a different spec I may have been better off. The supplier doesn’t give that option.

The final rivets went in. I used the ‘soft’ type and they really improve my riveting!

The striker was glued and riveted. It is thick enough so I can thin it out just a little if I want to get a stronger latching. I’m happy enough for now.

Here’s the hinge in action. In practice I’m not going to let it spring open so violently. I’ll need to develop a technique that is also safe for my fingers. The big deal for me is that one door allows me to service both oil and coolant.

I will make the fit perfect when its time to prep the cowl for painting. It’s not too bad now and time to cross this job off the list.