| Date: 05-19-2024 | |

| Number of Hours: 4 | |

| Manual Reference: 23 |

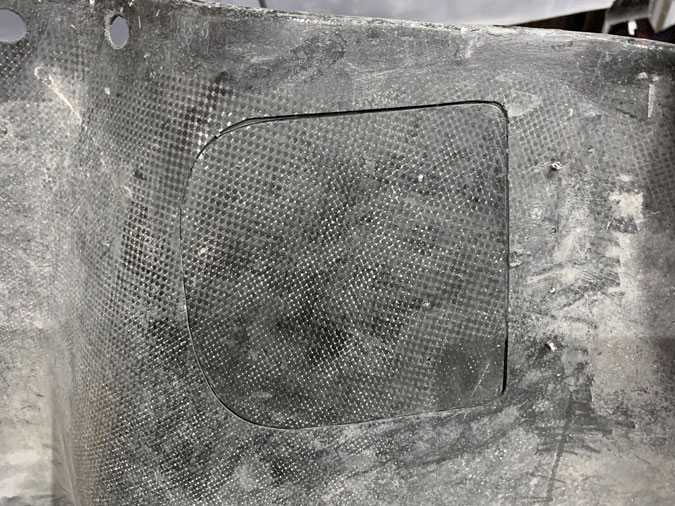

The oil door is one of those side jobs useful when I’m waiting for a part or some other hold up.

I’ve added a piece of 2024-0 so its bends easily give the cowl has a great curve here. I’ve just epoxied it on to form a strong lip.

Next up was positioning the hinge and door with hot glue to ensure I have the geometry correct.

It seems to work OK with the door allowing good access.

Next up was to drill a few holes and add clicos to again ensure the door is opening and closing OK.

I found the four clicos distorted this hatch too much. I’ve just gone for one each end and after this pic I’ve added some micro slurry to ‘add in’ to the middle curve so that the hinge and attached door rests on a solid support.

The door seems to work OK now and it will only need a small amount of filler to make it flush.

The next step is to add a few soft rivets after the cure, as you can see this is now done.

With the edges trimmed it is as wide an opening as I can make for this size door.

As you can see it has quite a spring which is what I wanted. A strong opening so its one or the other… and inline with the airflow if I ever forget it.