| Date: 04-06-2016 | |

| Number of Hours: 10 | |

| Manual Reference: 13-9 |

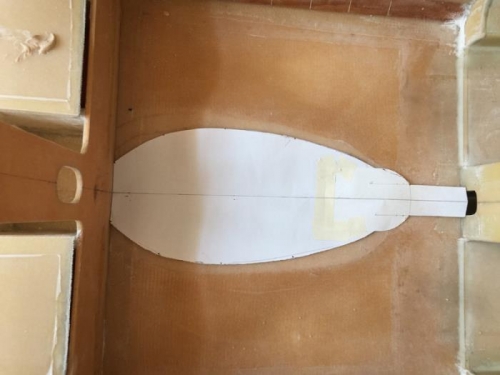

NB is the nosewheel box and is usually bought from a supplier. I do have a plans male mold but I wanted a different size…of course. As you see in Pic 1, I want to seal the whole area between the IP (instrument panel) and F22 on the floor. I also have the idea that if I can make some flat surfaces, this would be a place to mount electronics. I could just glue a hardpoint with nut plates to the top and mid areas of the box.

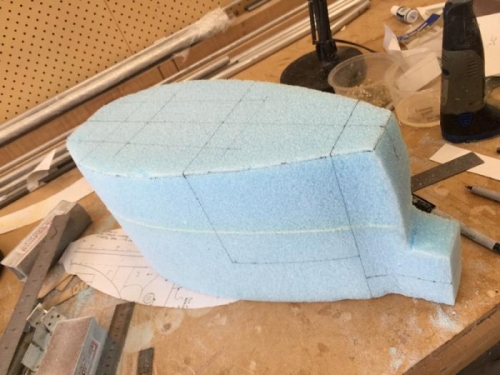

First up after making a base silhouette template was rounding up some blue foam for carving. I didn’t have anything thick enough so a couple of pieces glued together works. Then I spent a while roughing out the shape and slowly carving it to the minimum. Its about 1.5″ higher than plans so the wheel can move in a little deeper. The other factor was as slim as possible as this does restrict leg room. I just went plans thickness here as its works out OK in the flying plane I have.

Since arriving at the shape in pic 3 I have covered it in micro. When thats dry tomorrow, a good sand and maybe another coat and I should have a male mold.

Nose box shape

Foam roughed out

Final plug shape for NB