| Date: 03-21-2024 | |

| Number of Hours: 50 | |

| Manual Reference: 23 |

After more work and endless fitting of the cowl I realised that this heat exchanger does not fit as I had hoped. So I refitted the RHS radiator to move it about an inch or so up towards the wing. This was to give more space for the water hoses that were not going to work out from where this heat exchanger was. That was a week’s work,,,

Then back to remounting that Laminova heat exchanger… again.

So I figured it would go here.

Just miss the throttle-body inlet with some fancy bends to get the angles I thought I wanted.

Lots of fitting with my prototype piece and I went to make the ‘final’ one. HA!

So I make another bracket. That was a fail, or lets call it another ‘prototype’ and back to seeing how to fit it again. By now I’d moved the radiator again and that was a mammoth job…again.

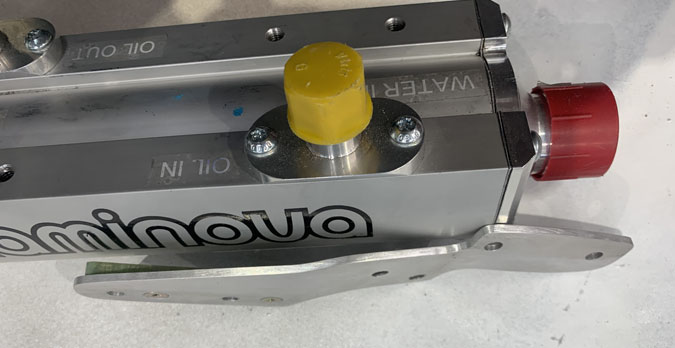

It looks clear in the pic here. The problem is that RHS corner was too near the cowl bottom. The rest of the unit is fine.

So I made another fancy bracket. Note this one has a bit of a bend at the left side attachments? then two bends after that. I seem to have a 2D brain where as a 3D brain is better for this stuff. So it takes a while.

Here’s my prototype again which I kept re-drilling and playing with and putting the bottom cowl on and off for.

So I got all excited and made another one to be the ‘final’ piece. After installing it and thinking I was OK I realised that the cowl wasn’t quite seated in its final position and this was yet another epic fail.

Even worse the local expert sheet metal guy walked pasted and said, “Is that commercial grade aluminium?”. “It will crack.” Well I am going to support it both ends, but he is right. He had a scrap of 6061-T6 although 2024 T3 would have been fine too. Anyway I’m getting better at roughing out this shape.

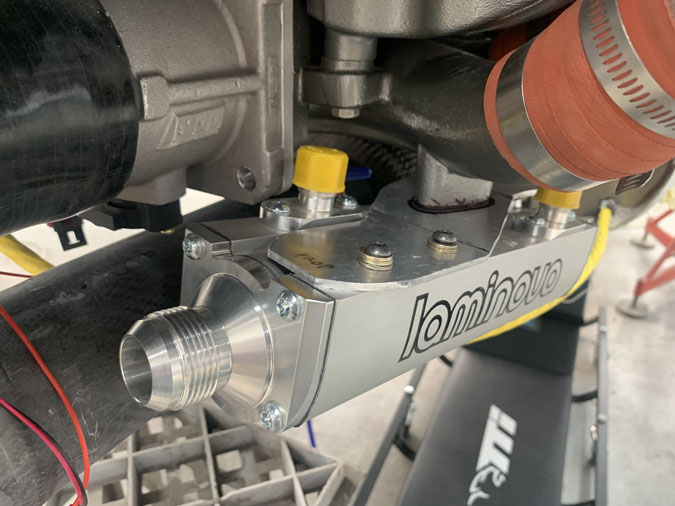

I got very busy for a couple more days and the one on the right is the final piece. The green thing (G10) is a spacer for the offset bend so I can screw the unit hard onto the bracket.

Its a funny shape but it works.

You get two pics here. Not because its interesting but because it took so long to get right!

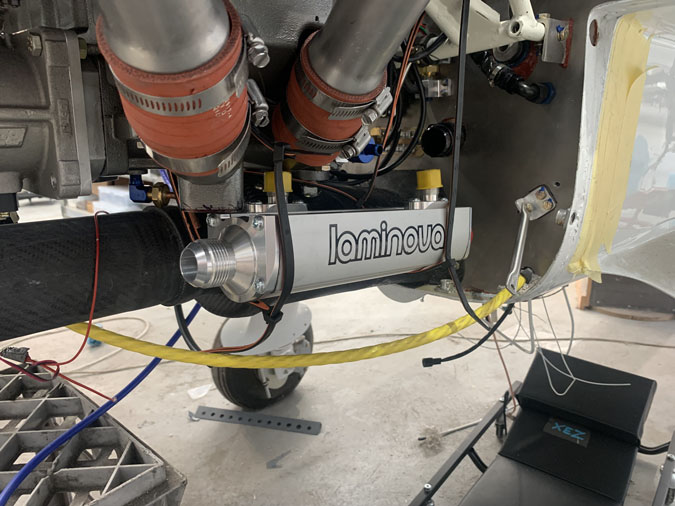

This is the unit in place. Its hard to see but I went to a LOT of trouble to position this so the oil connections could work. Notice the one at the front where you can just see the block hose fitting in place.

Here’s an overview of where it sits relative to everything else. The fun’s not over yet. This unit needs two more support brackets fore and aft. I want it rock solid to the engine which we all know shakes. I have concerns about all the stainless steel support rods I have on this thing. Cracking is something I will keep my eyes out for. Here I can use short angle brackets to get the job done so it might last.

I’m not going to document refitting the radiator here. The pics look almost the same as the first fitting, but it was many hours of work which I’ve included in this entries log.