| Date: 03-08-2024 | |

| Number of Hours: 22 | |

| Manual Reference: 23 |

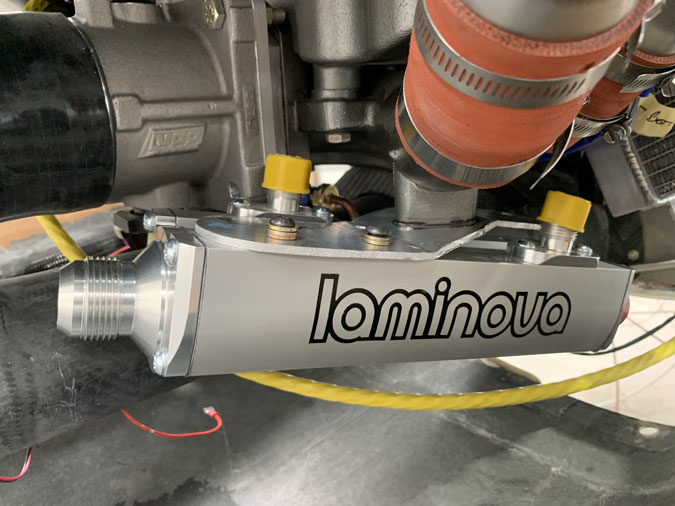

This is all about mounting the Laminova oil to water heat exchanger unit. The model is EC54 which is a double core and I spent months sending data and emails with then in the UK ensuring the unit was tweaked exactly for maximum efficiency for my application.

The Laminova weights in at a hefty 3lbs 15.8ozs. The oil cooler (cooled by air) that I was going to use weighs 4lbs 2.3ozs. So they are within 2.5ozs and that would not determine which to use.

It will go somewhere about here.

The idea is that cooled water comes AFTER the radiators have taken out heat and into this unit. The water flows through and exits at the aft end and then back into the engine. Oil from the engine in/out also goes to the unit and gets cooled.

The concept is that I am not introducing more air into the cowl, slowing it down through a radiator and then exiting the plane, slower than it went in so I would then have additional drag. No one likes that.

Of a couple of places ‘possible’ this is the only area that is going to work. I have to get two hoses in and two out so their ‘run’ is also very important. If I can keep the hose directions as straight as possible this also helps with the cooling efficiency.

With the bottom cowl on the unit is ‘almost’ clear. I’m good at the ends, top and sides, its just at the bottom I might have a problem.

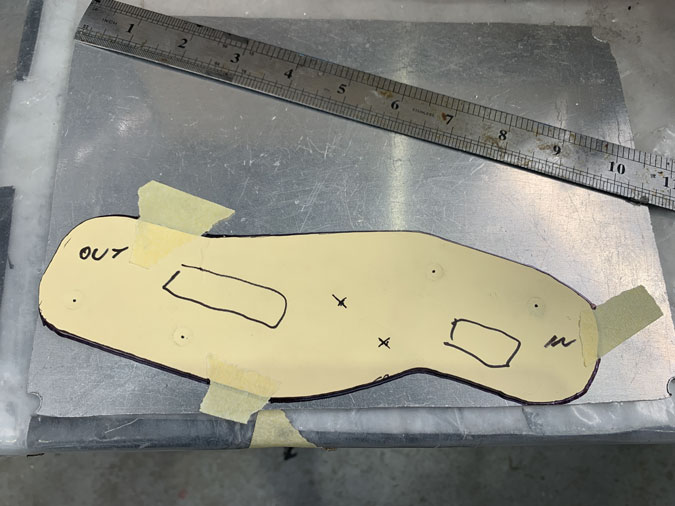

After a LOT of thought and different ideas for mounting I think a simple bracket might just work. Using my CAD skills (cardboard aided design) I came up with this first draft shape.

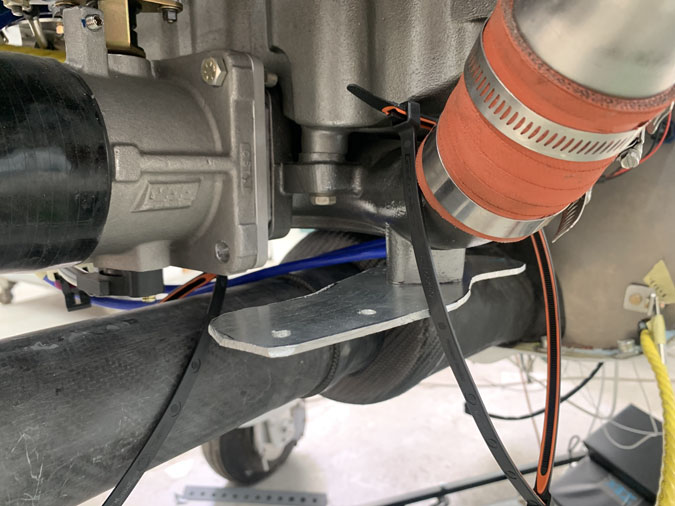

Using the sump attachment point looks pretty secure.

It works as a start. I’m thinking I might be able to tie into the nearby throttle body for a second securing bracket.

Maybe something like this for the exits too. (Later I gave this a fail and thought of something else)

OK, it nearly worked. I’m just touching the bottom cowl. 75% marks when I need 100% for this exam.

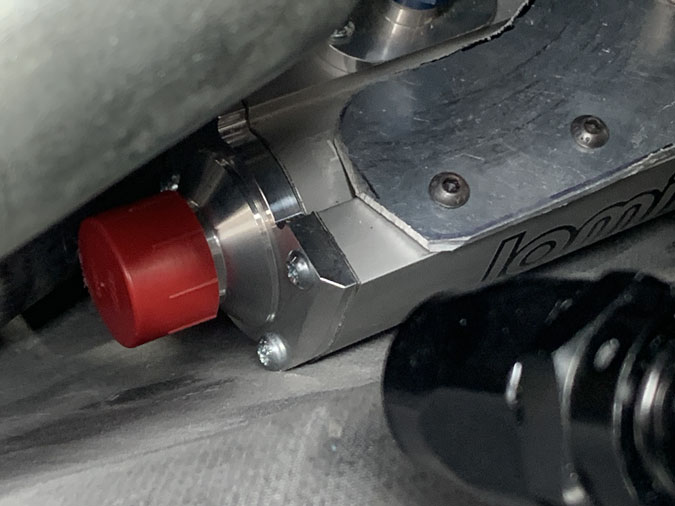

There is plenty of room forward under the unit. After more head scratching I made a joggle using the big metal brake bender. I can slant the unit and just add spacers for the forward screws. Something like this will work.

It was still a bit tight on the bottom.

I found that if I slanted the bracket inboard I got much better clearance. I’ll have to reposition the sump boss holes, but thats easy and the first bracket is a prototype anyway. The good news is that this position is going to be doable and I have some fresh ideas for the hoses.