| Date: 03-22-2024 | |

| Number of Hours: 8 | |

| Manual Reference: 23 |

With the central bracket made this heat exchanger is still unsecured. It would move in flight and eventually the holding bracket would fail. However if it is held, immobile, with a fore and aft supports all should be well.

I spent a lot of yesterday making these two pieces to fit. While it is not exactly fancy, when tightened up it really holds its end up. Of course I spent the time to nutplate the back of the top bracket with maintenance in mind.

The prop end brackets were very challenging. This is my second attempt and I have gone for some 2024-T3 angle.

The back section was quite a fiddle to get in place.

Here they are roughed out. The fit is critical for this to work.

This was after many hours of work. The screws are countersunk with nutplates on the second fitting so you can still get a bolt into the heat exchanger without interference.

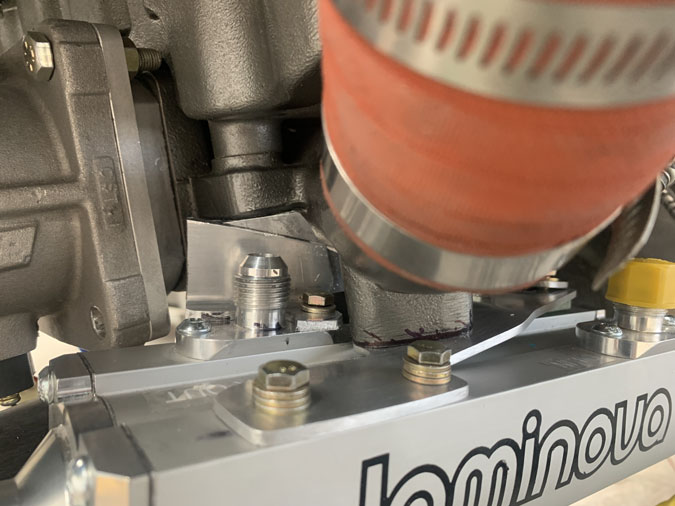

Finally I got it all screwed in place with various different fasteners. The black oil outlet fitting had to fit where things were very tight. I checked several times during all the placements.

This unit is now absolutely rock solid like it was welded in place. I need to get the radiators like this and I’m not sure how.

This was a VERY difficult install but like so many things on this build, it is in the past now. I can move on.

Here’s a bit of a look at how I’m planning to do these back hoses. All those fittings are very expensive and weigh more than I like. To me it’s a safety thing to get the best and do the best I can to ensure no leaks in flight. I will certainly be doing a lot of periodic checks on all these lines.