| Date: 03-08-2024 | |

| Number of Hours: 35 | |

| Manual Reference: 23 |

The right side radiator has returned from the welder. It comes in at 5lbs 2.3ozs. The left side radiator is still MIA, with the core not yet delivered from the Queensland factory.

The welding is top notch.

Unfortunately many of the tabs are in the wrong place and that will have to be addressed.

Here’s the first shroud or duct that I made. This one just isn’t going to work out. I expected to have to make a second or heavily modify this one, even with just the final welding making a small shape change. I do have poof of concept.

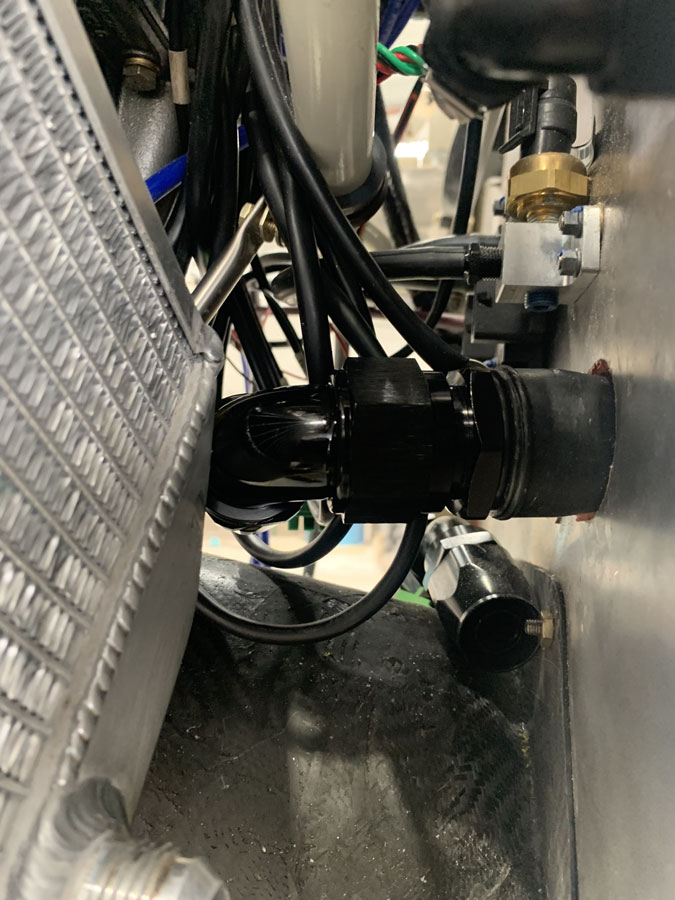

After spending a week and thinking I had this radiator position sorted out, I was wrong. The exit AN-16 pipe from the second water pump is just too close to the radiator lower end. I am going to have to put nearly a weeks work aside and go again.

Where that upper arm is used to be back near the engine mount.

So I need a new tab about here… I had that tack welded on at the airfield and kept working on the new position. Now it was getting a lot harder.

All the arms I’d made no longer work and will need to be redone. On the plus side it looks like I will have the radiator an inch or so further back. This is good news for my feeder expansion duct as the more space between the opening and the rad face the better for spreading out the incoming air.

Yes I got a little excited and put nutplates on all the tabs. Harder to do up in the temporary sense but a better option long term given dropping those tiny nuts is just what you do.

Why didn’t I get the memo on this? I spent a couple of hours trying to get the bolt done up through this P-clamp. Yes lockwire makes it possible. Apparently its a standard thing to do, I just didn’t know it.

I had to add a second clickbond to secure a new bracket for the end radiator tab. That was a LOT of work. Retrofitting is never ideal, time wise.

It has been a real juggling match to get this radiator into the new position. It must not touch, the top cowl, the lower engine mount, the engine mount cross brace and particularly the bottom cowl. The bottom and top cowls came on and off 20 or more times, it was not fun. I got 3 out of 4 right. This exam requires a 100% mark for a pass. The radiator touches the cowl at the front, so I’m not there yet.

I ‘think’ I can lower the mid cross-brace P-Clamp by one 1/4 hole height and put in a new nutplate. This will raise the rad just a bit to hopefully clear the lower cowl. Then I’d need to make some new SS braces to secure it. Wish me luck.