| Date: 10-10-2023 | |

| Number of Hours: 22 | |

| Manual Reference: 22 |

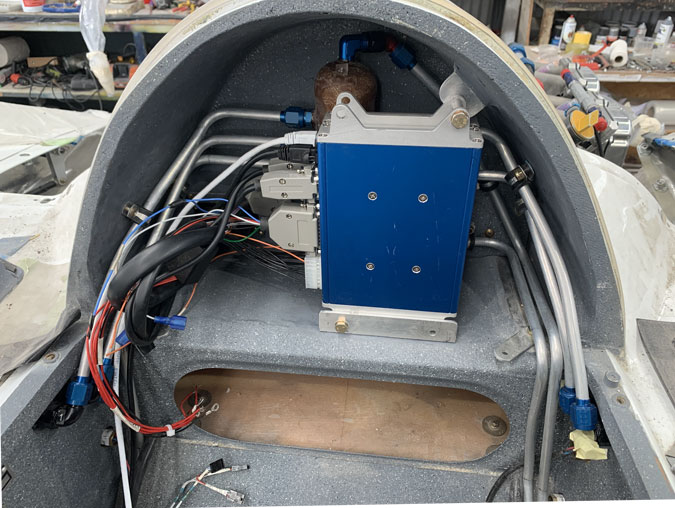

Two jobs here. Now I know where the expansion tank is going I can mount the plugs for the ECU’s. This is a ‘firewall penetration’.

I am getting very low on click bonds so I made a bunch of nutplates instead. Now I’ve sourced some more and ordered 50, next time I can go back to the more time effective method of glassing them on. However as the margins are really tight space wise these bad boys will do the job.

Of course while looking at the ECU plugs, now is the time to really nail down all those vent tubes in the same area. I started with embedding nutplates and then glassing over the top. You can just see three of them.

Back to the plugs. I thought about steel for fire protection…but who am I kidding, the plastic plugs will fail way before the aluminum plate! And, yes, old school file work.

I should have made the plate a little bigger but it will work out OK. The pre-drilled plastic mounts have made it a bit tricky.

I said it was tight, and I do want to keep holes in the firewall at a minimum. This took a bit of extra filing in the end to ensure the plugs had enough room to be put on and secured on the engine side.

Yes vent pipes on and off again. I keep checking to ensure I don’t snooker myself. This will work.

Again some glass over the top to settle it all down.

A bit of grey paint later too. I just can’t help myself. It doesn’t look like much, a few mounting holes but this took several days work.

The vent lines needed a tweak and a slight re-bend. In the end two with P-clamps and I’ll just cable tie the third. What I am doing is trying to get the tension off the vent plenum vessel fittings so they don’t fail.

So the vent pipes went on and off several times again and you can just see the screw holes on the left. The plugs seem to fit pretty well.

On the hot side, I’ll add a little fire protection goo later to seal that area from fumes entering the cockpit. As I said earlier, the plugs will melt in a fire anyway.

I still had the vents on the left side of the plane to secure. After a lot of fiddling and thinking with pipes on and off again I’ve gone back to clickbonds. I found I could secure the pipes on the alternator cover. The rest of the securing job will be done a bit lower than the turtleback next to the baggage hole.

Here we are with pipes secured (although not done up fully), and the ECU’s back in. They ARE plugged in behind all that wire. I expect a few more cable ties will be needed to clean this all up and then I have a nice upholstered cover to hide the lot!