| Date: 07-03-2013 | |

| Number of Hours: 10 | |

| Manual Reference: 9-3 |

This was a few days again lining things up. I repositioned the fuselage exactly on the center line of the bench and parallel to the end and all square.

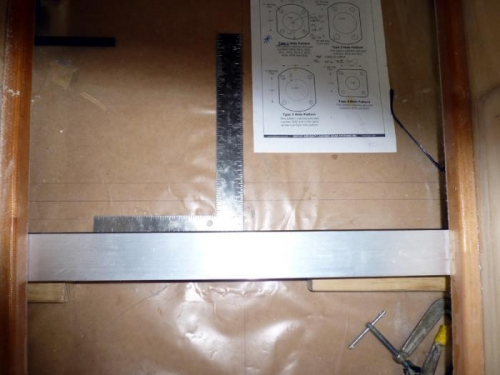

Next was to get a straight edge hard up against the longerons and measure straight up. 2.5″ less than plans and of course both sides need to be the same. I taped two rulers together and then taped a backing square of aluminium to keep it from bending. Checking was easy once I was set up.

Finally distance forward and aft needed to be the same both sides. In other words the axles the same distance from the rear or front so the aircraft can taxi straight once th nose wheel is correct. I was .26″ out so had to move the axle forward one side and back the other. So they are not 100% center of the gear leg but there is plenty of side meat and parallel wheels are important.

You can see plumb bobs located on the axles down to the big straight edge. A great way to get real positions.

This all took a lot of thought. You can see view holes in the jigs to help get lines visible on the gear pad template.

Checking the center line

Setting the axle height

Checking axle forward location