| Date: 12-23-2023 | |

| Number of Hours: 22 | |

| Manual Reference: 23 |

There is a bit going on here. As I continue this hose business I’m covering a few ‘hold down’ tasks. If not now…when?

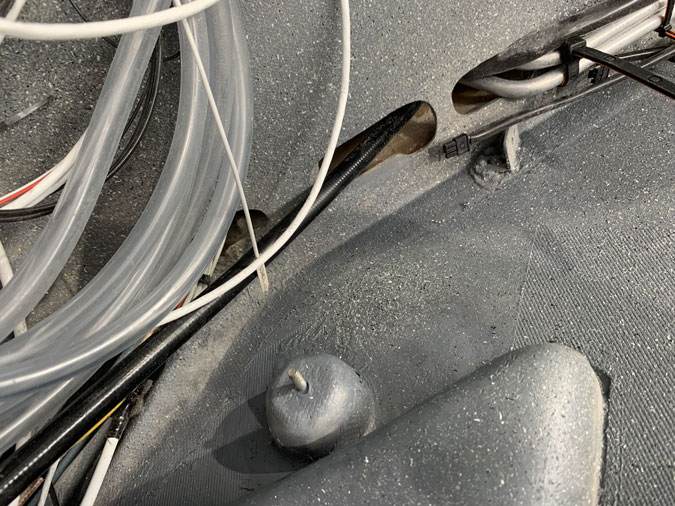

The left side cockpit return line fuel hose seems to hang in mid air so it needed a standoff that allows the hose to remain straight. This is a piece of blue foam carved to shape with a click bond on top and then two plies of glass.

After a bit it was bonded to the side which had paint removed first of course. Some glass around the base and then a little grey paint.

While obviously not done up you can see a good fit for the P clamp and then I did two slots at the end for a rubber faced reusable cable clamp. This was the easy side. On the right I’m still thinking how to do it with the main power cables, control pushrod, wiring and other stuff all in the same place.

I have gone to quite some trouble to get the right fittings for these hoses. Above is a regular straight fit.

This lower fitting is angled. There are 30, 45 and 90 degree options in this ‘Speedflow 200’ line. While they are not cheap, its a tidy way to minimise the bends in the hoses as much as possible. Teflon lined, these guys don’t like to bend too much, unlike the all rubber type. Keeping the fuel (or air) flows as smooth as possible with minimal sudden direction changes is also a goal with this install.

Again more trial fitting, this time with the fire protection cut to size.

This joins the two banks of injectors. I’ll be using standoffs and whatever works to secure the lines every 6 inches or so.

I don’t like how the hose is almost sitting on the engine here. I might add some rubber or the RTV impregnated glass I’ve made up for this sort of thing and sit it over the fittings.

Now this batch of hoses are sized and all the ends fitted they need to be tested. Again I went to 1000psi for at least 60 seconds on each hose. They are all fine.

I tried to get the special aviation dip for sealing the fire sleeve ends but none was available. I am NOT buying a few hundred dollars worth of stuff to only dip 8 ends. RTV will have to do.

Ready for installation.

Here I’ve added stainless steel straps to secure the fire sleeves. This was a bit of fiddling around and I did buy a special tool. The type of straps I ended up with self lock. So like a cable tie as you pull it through they say put. I just needed to get them tight or lets say, ‘firm’ and then cut the ends off. I gave a few hammer taps where the ends were just to make the sharp end sit down.

You can see here how I looped around the spark plug to ensure access.

This is a bit hard to see but it was SUPER hard to connect at the engine end. There is a restriction fitting on the -4 line right next to the left top engine mount. Connecting it was a few hours including reshaping a spanner to a minimum head size! In the end I took off the ignition block. That then gave access, I should have started with that in the first place.

This sensor is for oil pressure to the G3X. A lot of mucking around required! You can’t quite see where it goes on the engine. To see it you really need to take the engine off and I’m not doing that for you. Sorry!