| Date: 05-06-2024 | |

| Number of Hours: 18 | |

| Manual Reference: 23 |

Here we go for the last big layup of the whole build. The Left Hand Side (LHS) radiator duct.

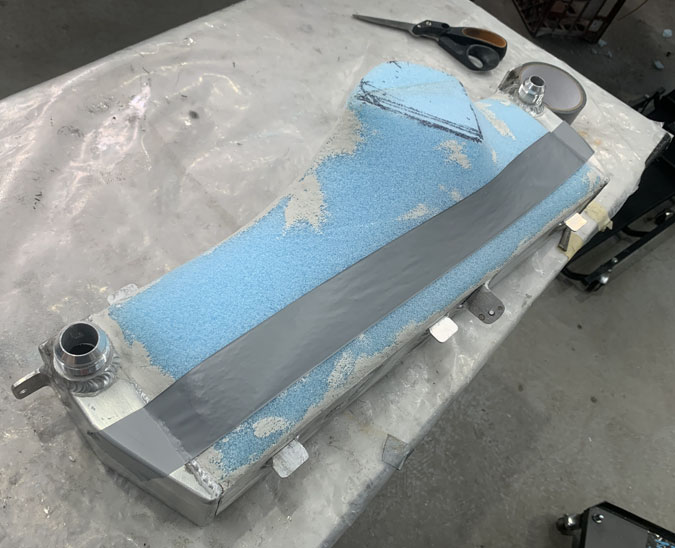

Starting off I got lucky and found a block of foam the right size.

Shaping it carefully, this stage was about getting the block to sit in place proving my parameters were a fit. That took a while as i was going carefully and wanted the biggest duct I could make.

The radiator sits just above a perfect match for the armpit scoop. This is necessary so the radiator doesn’t hit the cowl at any time. The margins are tight. You see how the entry point is offset? That requires a little extra foam to be grafted on, just as I had to do on the RHS.

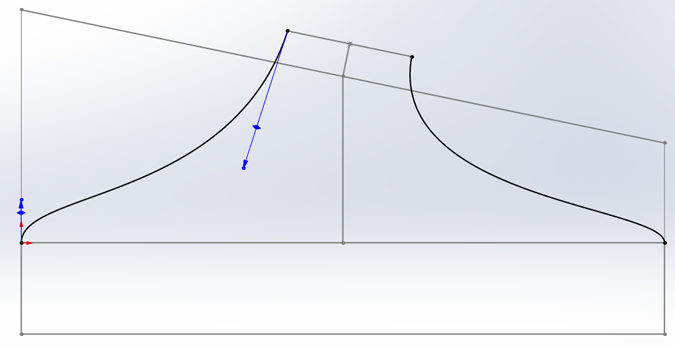

To get to this smooth state was just maintaining the shape I wanted and carving by feel and sight. A perfect 3D print generated by a computer based on ideal parameters would have been nice. Old school carving meant I had a shape in a a couple of days instead of never, given I don’t have a handy printer and the other skills.

More satisfying too. The air won’t know how the shape was made and the variation between ideal and a little hand sculpture is something I will never know in terms of aerodynamic efficiency.

See, not too far out. I couldn’t make the neck longer as there just wasn’t space! Maybe less volume on the LHS was possible? My carving felt about right so I called it good.

I used modeling clay to fill a few gaps then I started on the duct tape wrap.

All wrapped up and its time to cut some carbon cloth and mix epoxy.

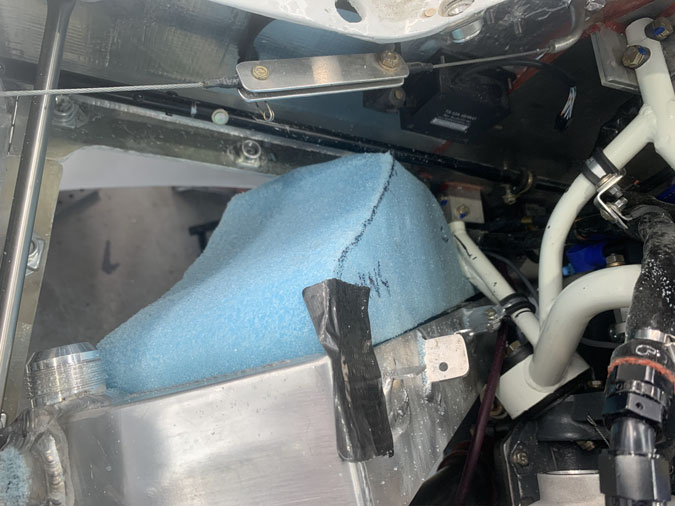

I went for 3 ply of carbon BID laid up on plastic and applied one by one. My epoxy takes a while to go off and it was about 16-18C in the hangar, barely the minimum to do the job.

It was a two day cure to get hard enough to begin the ‘release’.

Getting it off the radiator and cleaned up was a full days work.

I checked the fit was still good. We just cleared the cowl on the bottom. The final step was to add six nutplates. We are done, the LHS duct is built and the last big layup on this marathon build is completed.

Woohoo!!

‘

‘