| Date: 08-22-2015 | |

| Number of Hours: 6 | |

| Manual Reference: 20-4 |

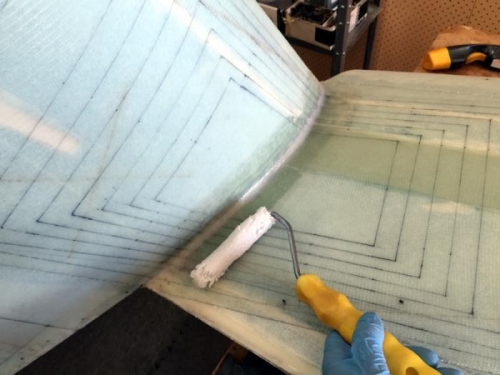

Layup day. The room was a toasty 26C and the epoxy warm. Pic one shows the roller I use. Microfiber head and I just love these things. A roller doesn’t work for every occasion but it is gold for the bigger layups and really works on UNI. I did the usual foil thing and only had a few straggly edges where I’d snip off a strand.

I put the inboard part of the wing on a chair which improved the layup angle so at least I was less than 90 degrees for the cloth.

This is now the 4th and final outside/inside winglet layups of this type. Key things are the roller, foil and using my fingers a lot getting things to sit correctly and having patience to settle the glass in place. By doing the glass on foil the UNI comes to the job with the correct resin to fiber ratio. The two BID pieces are wetted out in place but if you use the roller carefully, the cloth is never overly wet and given the angles you don’t want epoxy dripping anyway with a squeegee or brush application.

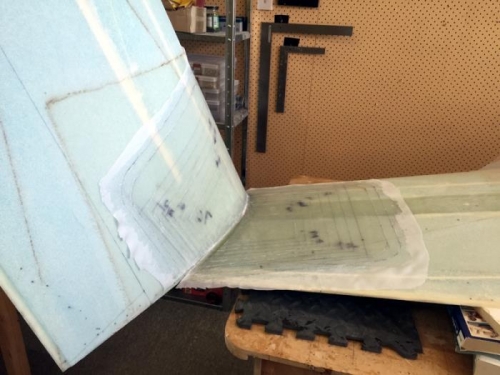

Pic three shows my winglets structurally attached. This is the last really big layup until its strake/fuel tank time. Lots of fun still to come on these wings for now.

Roller action

All plies and peel ply down

My tight working space