| Date: 04-16-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 19-4 |

After finishing the right wing hard points I went to the trouble of removing the wing from the jig and putting the left wing in to do the same job of installing three hardpoints and the two cutouts.

It took a few days and cure cycles. I thought as I’d just done one wing it was good to get the other one out of the way. I tried to do a better job this time and managed to fit the two ply of BID without cutting at the extreme point in the curve, I did get the BID ply to go around the bottom of the cutout. I would have liked the bias to be a bit straighter of course.

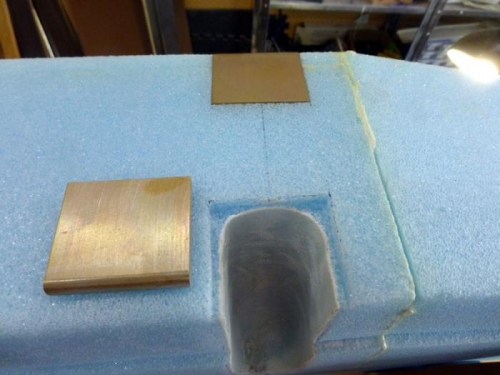

The job got done. Once cured, another clean up and then cutouts for the hardpoints were made with the router initially and then the razor blade and hand tools. I tried to do a better job than the other wing and it wasn’t bad. The thin metal covers were a bit of work as I tried to get a really tight fit. They get covered by the sheet web and spar cap but its still a part of the process to do good work and constantly be trying to improve.

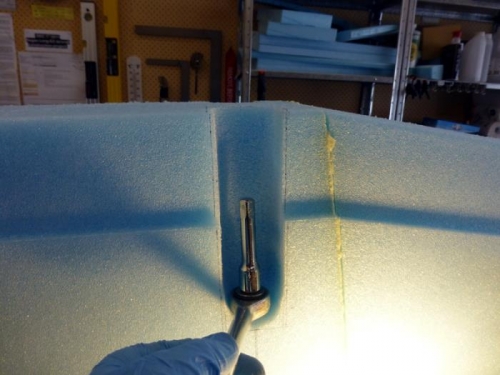

Initial cutout

Fitting the hard points

Left hardpoint done