| Date: 04-25-2018 | |

| Number of Hours: 7 | |

| Manual Reference: 21-3 |

I’ve been preparing the leading edge strips for some days now. 1.9″ wide and length as required. One ply of BID each side and the fuel safe epoxy.

As you can see above, there are three strips per side. This is similar to the plans construction except I’m not doing the fairing block or the kink in the strakes. I’m also making this LE nose area a little smaller than plans to allow more fuel.

After a lot of fiddling around I fitted the six pieces dry. As usual its not plans positions either. It makes more sense to me to have these stripe parallel to the leading edge of the strakes. I think the plans mean you to do that but on the numbers given I can’t see how.

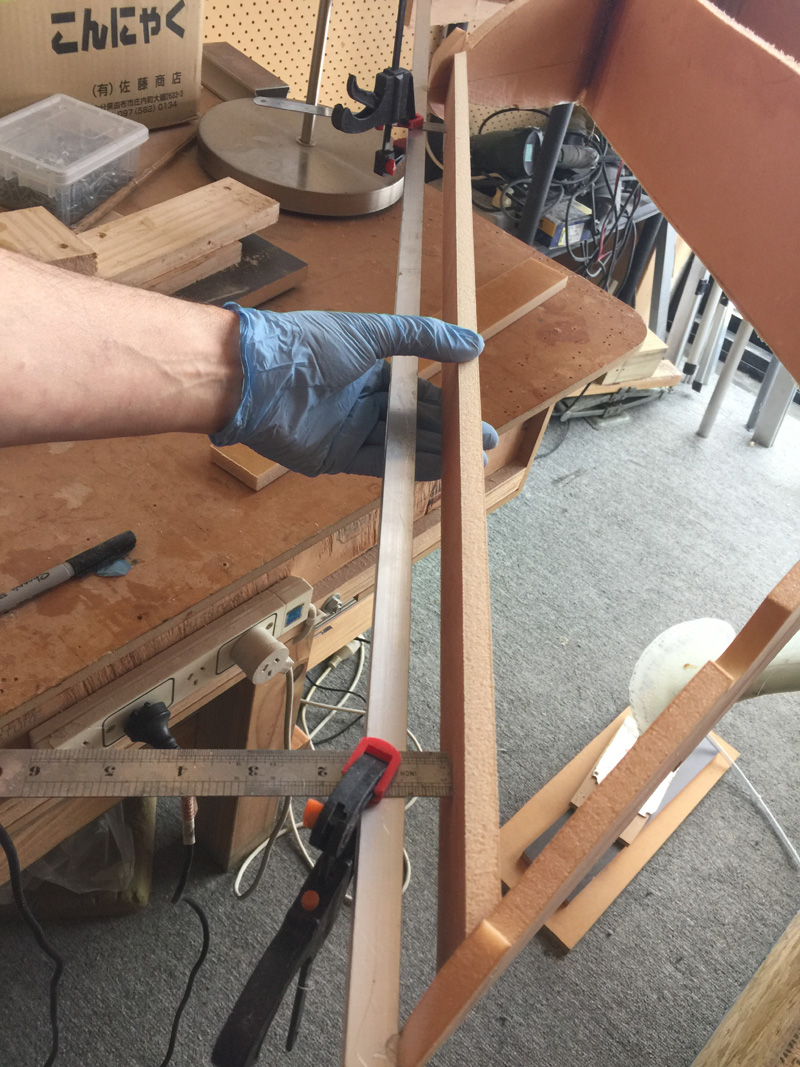

I worked on 0.7″ gap measure with those rules. That gave me a ‘fitting point’. I then floxed in a piece, clamped it in place. After that I hot glued sticks to the outside leading edge aluminium straight edge which is also hot glued in place. Then I retrieved my rules and clamps when it set. A guy only has so many six inch rulers.

You can see the result here. Those leading edge pieces will probably get a lot of careful trimming upper and lower to fit the tops and bottoms. I think the edge angles will need adjusting. All good.

Here’s another shot showing them reasonably straight. It doesn’t matter as its all internal, but I like to go for a straight line when I can.

Another view as I did the other side. More sticks and clamps. That piece was made from two pieces of foam I laminated together due to a lack of 12mm foam. Its not some fancy structural reason.

Again reasonably straight. I can remove those forward dowels once this cures, I have a box like structure in place.

The basic strake shape with ribs and baffles has arrived.