| Date: 06-20-2017 | |

| Number of Hours: 10 | |

| Manual Reference: no ref |

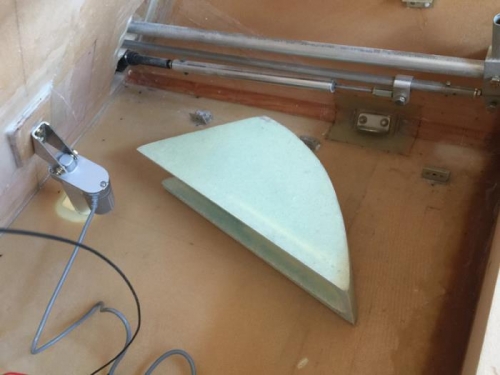

This just keeps going on and on. I scalloped out the insides of the cover and glassed it with one ply of BID. A day later it was nearly a fit. Another afternoon was needed to keep tweaking the insides.

It seems the wiring lead was catching a little and the edges needed just a touch off them to improve the fit. I also had to make hard points. Finally I’ve sealed the foam edges and where I’ve had to trim the insides too.

Tomorrow I’ll have a go at making the screw on angles fit so the box can be secured as you see in pic 3. This is not going to be something I’ll want to keep removing and reinstalling. The screw positions once the strakes are on is going to be hard to access.

It is quite a robust cover and it should take the pressure of the ferry tank pressing on it without a problem. Of course it is much heavier than I would like. About the weight of helium would be better.

Insides glassed

The fit

More fitting