| Date: 08-02-2016 | |

| Number of Hours: 10 | |

| Manual Reference: 13-11 |

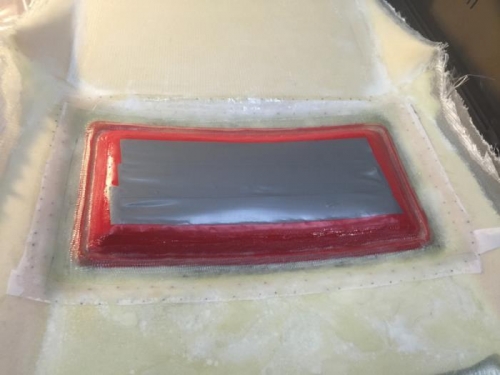

This began with some careful release tape work. I really didn’t want to have to bash the hatches out with a hammer later. Although I’m told that works quite well. I did just the edges first and then pressed the hatch back into the cutout. I made it as flush as I could and then added lots of hot glue on the top side. You can see this in the next log entry on the forward hatch. No need to duplicate every shot eh?

Pic 1 shows the three ply layup for each side. I interlocked them at the edges as I went like a pile of matchsticks. Probably a good third of what was laid up will be edge trimming. I might have gone for 2 ply but I was thinking too little can’t be sanded off as easily as too much.

I also added some thin cord which was taped over to make a ditch for some rubber seals later. If I was doing it again I think I’d omit this, lay up extra plys and route it out neatly instead. It was really hard to get the glass sitting nicely. I’ll think about this later. I may fill the ditch and route. No rush, I have the rest of the plane to build.

Once it cured and was trimmed I have a great fitting hatch cover as implied in pic 3. Oh yes and with some slow careful work the hatch did come out with no violence after cure. The top is not 100% perfect with the top skin but very close and within a bit of filler that will be done anyway at finishing time.

2″ Hatch edge tapes

Taped, laid up and curing

Edges cleaned and strong