| Date: 11-25-2023 | |

| Number of Hours: 5 | |

| Manual Reference: 23 |

This sump has been a saga. I wanted the induction facing forwards to meet the RAM air duct, not backwards where I would have to turn the air 180 degrees and use up a lot of under the cowl space.

Initially it was to be the Skydynamics cold air induction sump. The engine builders tried hard but it just couldn’t be made to fit. I had sent detailed dimensions of my ‘space’ but this was not enough.

Next up they arranged for a helicopter sump and modified it to fit. Again communications over the Pacific failed despite my best efforts. What arrived was huge and I couldn’t even put the lower cowls on. It was facing forwards but there was zero space for the air filter and no room for the radiators either.

A Superior rear facing cold air induction sump was later sent. This fits a treat but the air intake is pointing the wrong way. Did I mention it fits?

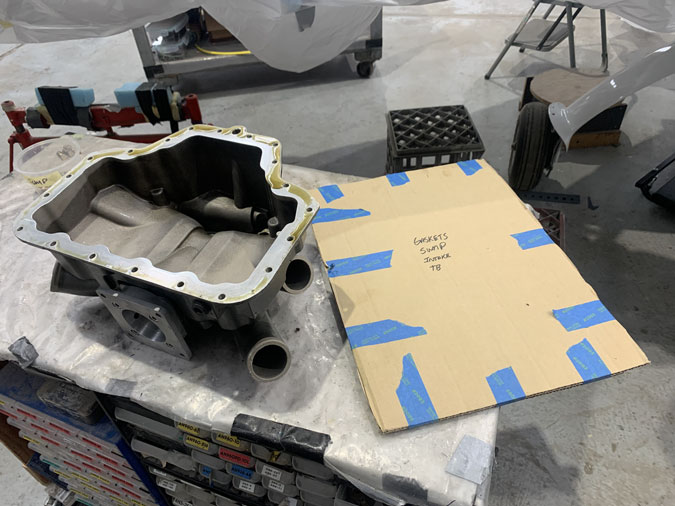

In case you missed other posts, here it is. The sump is just held on with four bolts for now. I have dealt with the rear facing, but at the cost of turning the air and eating up the space I wanted for the oil heat exchanger. The 180 turn has been OK’ed by a fluid dynamics expert as not a big issue given I have already slowed the air in a plenum.

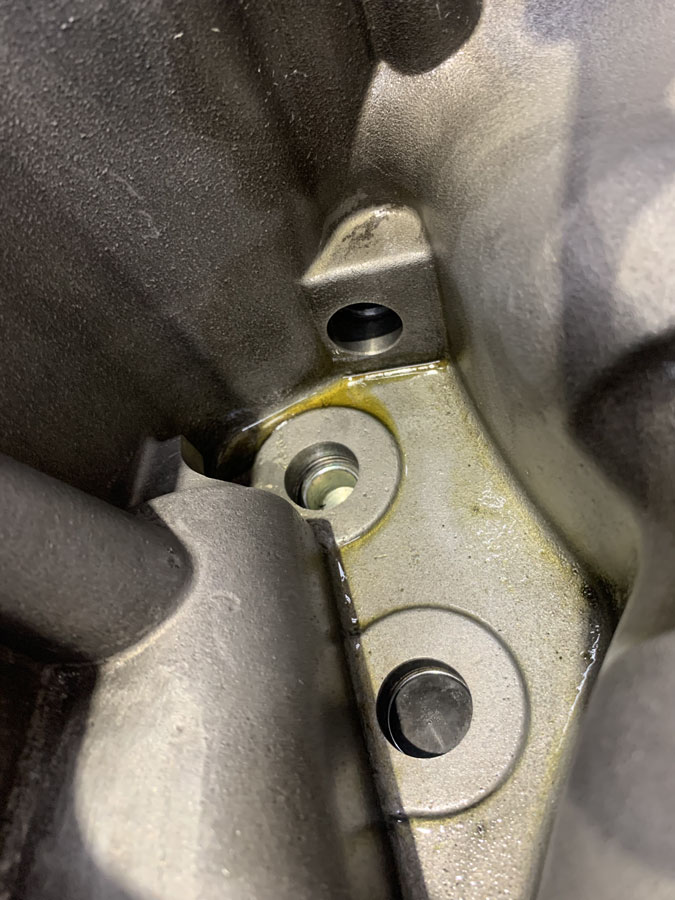

To do oil changes, I’d have to remove the induction! As a fix I have ordered a quick drain fitting that will go in the side hole you see above. It will get most of the old oil out, maybe all of it if I raise one wing. I can do the main plug at each 100 hourly which might be a time to find out how much is really left that the quick drain misses. If its none… I will remove the bottom fitting and just put a plug in.

I spent a while doing the usual clean up, but it was pretty good, I just had some gasket residual to deal with. The engine has only done 25.2 hours on the test stand.

I sourced longer bolts than were supplied. These are the standard Lycoming/Superior spec. A smear of 515 went on both sides of the gasket.

Torque was 95 inch pounds, the standard for 1/4″ bolts. I used thin washers to ensure I had some thread showing. I could have used one thin and one thick except at the rear center. Am I getting too fussy? There is threat all the way with these bolts so they are impossible to ‘shank’.

I’ve put the runners on too. Again a smear of 515 on the gaskets. This is the ‘final’ fit up for the sump story, I hope. The throttle body however is just bolted up loosely as this will come off and on again as I sort out the throttle cable.