| Date: 02-18-2018 | |

| Number of Hours: 10 | |

| Manual Reference: 18-7 |

This has been off and on since late last year. I found that the plans canopy hinges were not wide enough because of my enlarge canopy footprint. So at great expense I ordered a wider hinge. That arrive after a few weeks and I soon realised I’d messed up and I needed an even wider hinge by about .25″ Well the cost of that one was enough to make you weak at the knees. Like nearly $450. I had to order a length of 72″, I needed 16″…. AND it took more than six weeks to arrive.

So for those who care thats an MS20001-12 Aluminium Hinge, Butt. I just think of it as a hinge that is 1.75″ wide when folded. Wide enough. Let me know if you need some.

This is all I needed. 2 X 8″

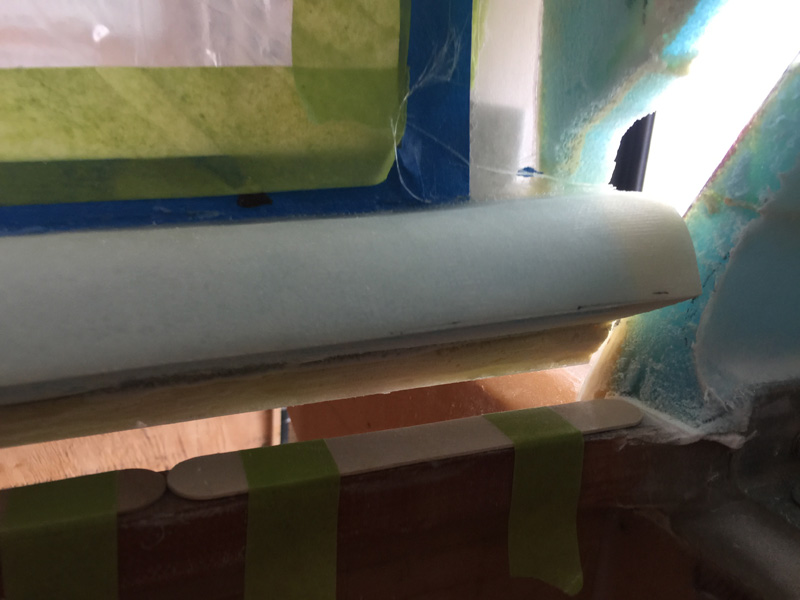

I’m jumping the gun a bit here but I wanted to show you how these hinges line up. Before that some hours were spend inlaying the hinges below the top of the foam as you see above. That meant grinding out some hardpoint material. The canopy was refitted multiple times to ensure the cutout was deep enough. Fun and games.

Yes I was very lucky to have John C. a Quickie builder and pilot, given me a hand for a few hours over a couple of days. Moving the canopy is 100% a two person job. Thanks John!

Here’s another shot showing that the important part is in line, the hinge pins. I thought this was going to be really difficult and had ideas about installing a long length and then cutting away the middle after it was drilled out to ensure the hinges were perfectly in line. Naaaa, I was wrong, it’s easy with a couple of rulers. The trick is to ensure the canopy opens correctly, meaning that the hinge line must be far enough out towards the edge of the fuselage.

Meanwhile I was thinking ahead that the bottom of the canopy rail is yet to be glassed and I need to ensure that the canopy will sit back down far enough after four plies of glass. If it sits Ok with a tongue depressor as a spacer that means I’ll have more than enough of a gap.

You can’t see it, but the hinges fit in their slots and the canopy sits on the longerons with a reasonable gap. A smear of micro later and it will be perfect. John was again a huge help getting that big heavy canopy in the frame on and off.

Having spent some time cutting down the right canopy edge in anticipation of the required clearance when opening, we were up to trying it out. I covered the hinge area with gaffer tape and hot glued the hinge and canopy top to that.

Given the weight of the canopy that hot glue became a pivot point. It needed to sit down while we tested the opening clearances. While John held things open, I added a couple of clamps to keep the hinges down where they needed to be.

Here’s another shot of the same thing. Obviously you can’t close the canopy now.

Here’s how you can hold it open if you need a rest.

This is the canopy where we opened it wide and there is massive clearance. You’d think way too much BUT… I still have to build the sides out straight rather than curving inwards. This is yet another legacy from the canopy being blown too wide that I’m working around. It will be all good in the end and I will have my ‘French’ canopy. The hinges seem way off from the edges but trust me it will all be well supported eventually and might even look like this is what I intended. Ha!

With the hinges in line and 5mt glued in place and everything checked, I went to make 8 marks for the screws. To my horror then I used the center punch the 5mt glue gave way. Fortunately I was able to re-position it exactly using the glue witness ridges and yet again endless checking with straight edges. That was when I got a little excited with the hot glue gun.

Now we have some holes where they should be and I can continue on tomorrow drilling them up for the bolts. After that I can take the hinges off alodyne them… oh, I’ll tell you all about it later. There is still a bit to do before the hinges get attached to the longerons. I am very happy to be getting this done.