| Date: 12-11-2023 | |

| Number of Hours: 14 | |

| Manual Reference: 22 |

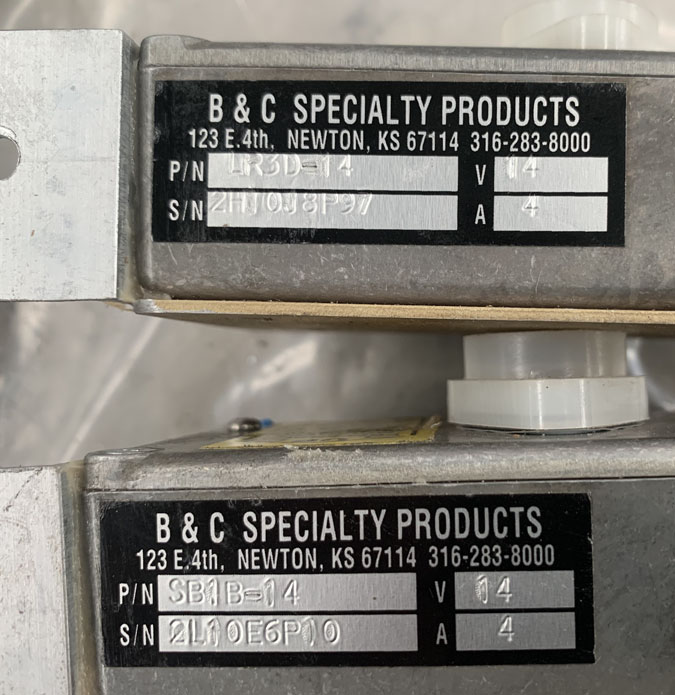

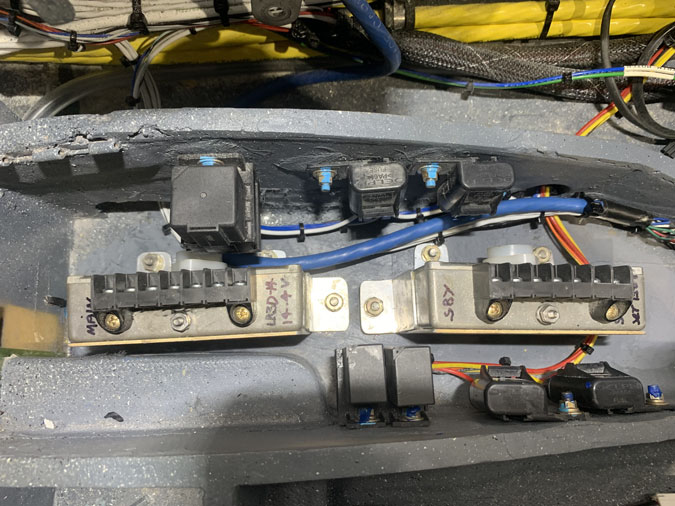

The two alternators, the main belt driven and the aux or standby spline driven require external regulators. Many alternators have these built in. I have gone with the very reliable B&C LR3D-14 and SB1B-14 instead to match the 60amp LX60 main alternator and BC-662-H 35-60amp standby alternator.

Initially I was trying to install them as closely as possible on the cold side of the firewall. This meant either the hellhole or squashed into the turtleback. Both locations were a big install problem, particularly with the manufactures recommendations on a label stuck to the units.

I wrote to B and C and it turns out that even under the canard would be OK as long as they didn’t get wet! My preferred spot of under the seat got the go ahead. This meant I could also get the weight forward as well as a more straightforward mounting (so I thought) and easy access.

This was a really easy spot for mounting the units for once, but it took up a lot of room. I could use that area for storage, or even for ballast if I need it. So I had to veto it as a position.

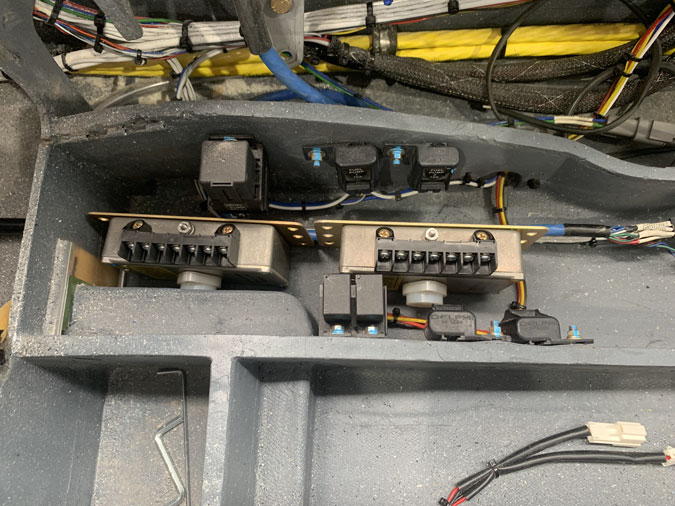

This was a much better spot as it was already in use for ‘electrical’ but the install suddenly got trickier. I’m used to that by now.

I went ahead and cut off the mounting ears to fit my own. I borrowed a special epoxy to glue on the aluminium tabs. Bonding Resin MGS BPR 135G3 and Hardener BPH 135 GG (from Ironbark Composites)

Here are the details, in case I need them later.

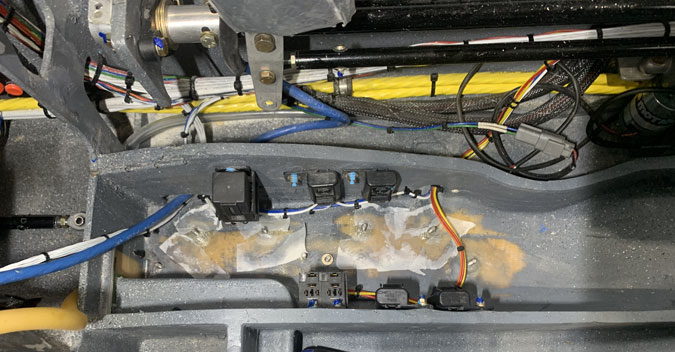

I did the usual thing of mounting clickbonds and two plies of BID over the top. Once cured a lick of paint too.

I cleaned it all up and mounted the units. Done and dusted? Nope. They were just not secure enough, the floor is a little cured here so that was an issue too. I was not happy. So here we go again…

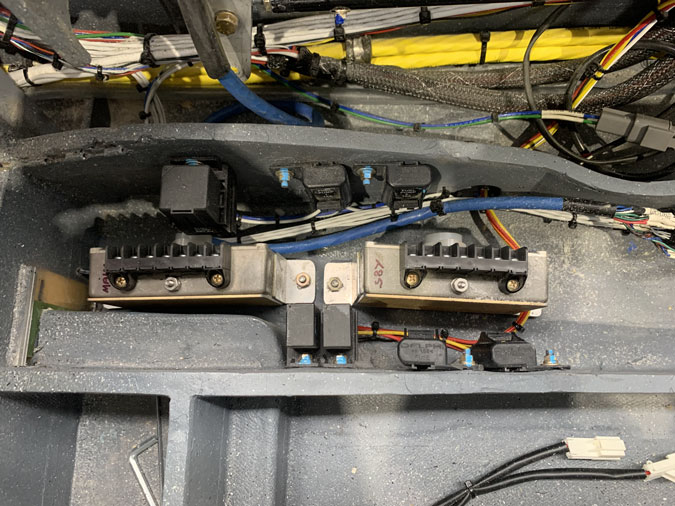

The same process. I made another 2 tabs for each unit and mounted them. This would have been a LOT easier and quicker if I’d done four in the first place.

I spent quite a while sanding off the paint in the area. Then it is the process of gluing the clickbonds into position. Once set then take off the regulators leaving the ‘positioned’ threads. Then eight pieces of 2″ diameter glass (2 ply) individually laid up. Then peel ply, then let it cure. Then remove that. Then add some grey paint. The same process as before.

Now we are all done (again). This time it is four fasteners per regulator and they are ROCK solid. Ready for wiring, I can move on to the next job. Yes this was a bit of a PIA but a good result in the end and a great use of my precious space. This was well over two full days of work.